Back to all water valve

Butterfly Valve Manufacturer

Butterfly valve is a type of quarter-turn valve used to control the flow of liquids, gases, or slurries. It consists of a circular disc (the valve’s “butterfly”) that rotates 90° to either allow flow or shut the flow off. When the disc is parallel to the flow, fluid flows. When the disc is perpendicular to the flow, the valve stops the flow. You can also rotate the disc partially to throttle the flow.

As a china manufacturer for butterfly valve, we can produce wafer type butterfly valve, lug type butterfly valve ,flange butterfly valve and groove ends butterfly valve as below.

Butterfly Valve parts

Butterfly valves have a few main parts that are the same in all types of butterfly valves, but they can vary a little bit depending on the design (wafer, lug, flanged, or groove butterfly valves).

Valve Body: The main part of the valve that holds all the other parts inside. It is designed to be installed between two flanges in a pipeline.

Valve Disc: The part of the valve that rotates to control the flow of fluid. It is usually round and made of materials like stainless steel or nickel alloys.

Valve Stem: The part that connects the actuator to the valve disc, so that when the actuator moves, it makes the disc rotate.

Seal (Seat): The material that seals around the valve disc and body to make sure the valve doesn’t leak when it is closed. Common materials include EPDM, PTFE, and NBR.

Actuator: The part (manual, electric, pneumatic) that makes the valve stem and disc rotate to open or close the valve.

O-Rings and Gaskets: These are used to provide additional sealing to prevent leaks around the valve body, stem, and actuator connections.

Types of Butterfly Valves and Their Parts

1,Wafer Butterfly Valve

Body: A small design that fits between two flanges and is bolted in place. The wafer valve body is usually thinner than flanged butterfly valves.

Disc: Same as the other types, it rotates 90° to control the flow of fluid.

Stem & Actuator: Same as the other types, the stem connects to the actuator to open and close the valve.

Seal: The seat is usually made of EPDM or PTFE, and it makes a tight seal between the valve body and the disc.

Installation: Wafer butterfly valves don’t have flanges on either side and rely on the flanges of the pipeline to hold them in place. This makes them less expensive and smaller.

2,Lug Butterfly Valve

Body: The body has threaded lugs (protrusions) on either side that allow the valve to be bolted between two flanges.

Disc: Works the same as other butterfly valves.

Stem & Actuator: Works the same as wafer and flanged butterfly valves.

Seal: Usually made of EPDM or PTFE, depending on the application.

Installation: Lug butterfly valves are easy to install and remove without disconnecting the entire pipeline. The threaded lugs make them great for systems that need to be maintained or disconnected periodically.

3,Flanged Butterfly Valve

Body: Has flanges on both sides, making it easy to bolt directly to flanged pipe ends. This design provides a stronger, more secure connection.

Disc: The disc rotates to control the flow of fluid, just like other butterfly valves.

Stem & Actuator: The actuator is connected to the stem to control the opening and closing of the valve.

Seal: Common sealing materials include EPDM, NBR, and PTFE, depending on the medium.

Installation: Flanged butterfly valves are bolted between two flanges, making them stronger and more reliable for high-pressure applications compared to wafer or lug types. They are used more often in applications where a strong seal and high pressure capability are needed.

4,Groove Butterfly Valve

Body: The valve body has grooves on the ends that allow it to lock in place with grooves in the pipe or mating components.

Disc: The disc is the same as other designs, rotating 90° to control the flow.

Stem & Actuator: The stem and actuator work the same as other designs to control the operation of the valve.

Seal: The seal material can vary (EPDM, NBR, etc.) based on the application.

Installation: Groove butterfly valves are designed to fit into grooved piping systems. They are typically used in applications that need to be installed quickly and are good for systems that use grooved pipe fittings instead of flanges.

Summary of Differences by Type

| Component | Wafer Butterfly Valve | Lug Butterfly Valve | Flanged Butterfly Valve | Groove Butterfly Valve |

|---|---|---|---|---|

| Body | Thin, compact, fits between flanges | Threaded lugs for bolting to two flanges | Both sides have flanges for bolting | Grooved ends for locking into grooved pipes |

| Seal | EPDM or PTFE | EPDM or PTFE | EPDM, NBR, or PTFE | EPDM, NBR, or PTFE |

| Installation | Bolted between pipe flanges | Can be installed and removed without disconnecting pipe | Bolted to flanged pipe ends | Locks into grooved pipe system |

| Applications | Cost-effective, space-saving | Suitable for systems needing periodic maintenance | Heavy-duty applications | Quick installation in grooved piping systems |

Choose Right Butterfly Valve

Choosing the right butterfly valve depends on the medium, pressure, temperature, installation method, and sealing material of the pipeline. Here are some recommendations for different scenarios:

Water Supply Pipeline (Clean Water, Drinking Water)

Recommended Butterfly Valve Types:

Wafer Butterfly Valve: Suitable for low and medium pressure water pipelines, compact and light, suitable for small space.

Lug Butterfly Valve: Suitable for pipelines that need to be removed for maintenance or segmented water supply.

Flanged Butterfly Valve: Suitable for large diameter pipelines, stable installation, better sealing.

Sealing Material: Soft seal (EPDM, NBR), no pollution, in line with drinking water standards.

Valve Body Material: Common materials are ductile iron, stainless steel, carbon steel, and the inner lining is epoxy resin or rubber to prevent corrosion.

Other considerations:

Must meet NSF, WRAS, or other drinking water safety standards.

Consider water hammer, you can choose butterfly valve with slow closing function.

Flanged Butterfly Valve For Water Supply

Oil Pipeline (Crude Oil, Refined Oil)

Recommended Butterfly Valve Types:

Lug Butterfly Valve: Easy to remove in one direction, suitable for pipeline maintenance.

Double Flanged Butterfly Valve: Suitable for high pressure, large diameter pipelines, more stable sealing.

Metal Seated Butterfly Valve: Suitable for high temperature or oil transport with solid particles, durable, heat resistant.

Sealing Material: NBR (oil resistant rubber) or metal sealing to prevent seal degradation due to oil.

Valve Body Material: Carbon steel or stainless steel, resistant to corrosion and oil.

Other considerations:

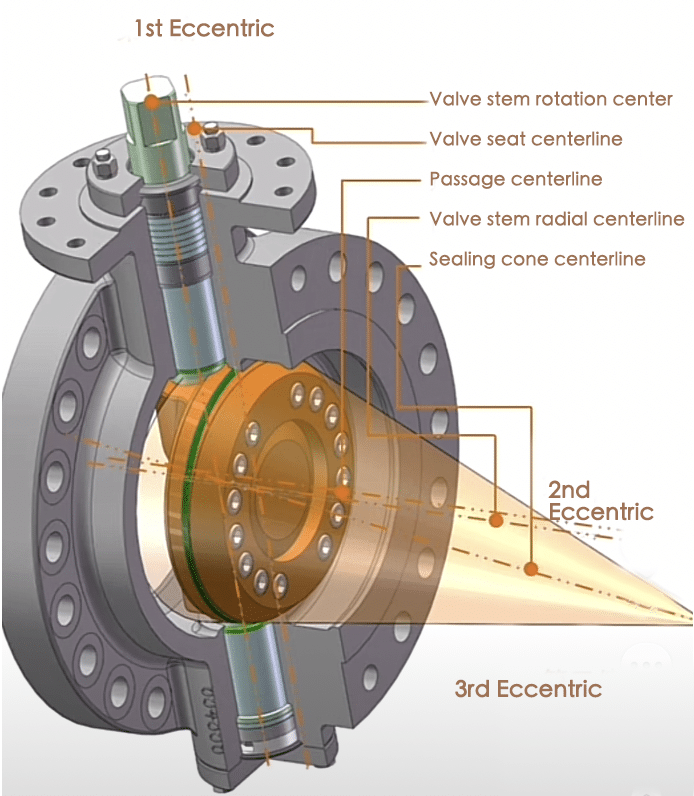

For high pressure oil pipelines, it is recommended to use double offset or triple offset butterfly valves to minimize seal wear.

Must meet API 607 or API 6FA fire safety certification.

Gas Pipeline (Natural Gas, Liquefied Gas)

Recommended Butterfly Valve Types:

Triple Offset Metal Seated Butterfly Valve: Suitable for high temperature and high pressure gas pipelines, excellent sealing, long service life.

Lug or Double Flanged Butterfly Valve: Suitable for low and medium pressure gas transportation, easy to install and maintain.

Sealing Material: Metal sealing or PTFE (Polytetrafluoroethylene) to ensure high gas tightness, no leakage.

Valve Body Material: Carbon steel or stainless steel, resistant to pressure and corrosion.

Other considerations:

Must meet API 598 test standards to ensure zero leakage.

Must have anti-static and explosion-proof design to prevent spark generation.

Chemical Pipeline (Acid, Alkali, Corrosive Fluid)

Recommended Butterfly Valve Types:

Fully Lined Butterfly Valve: Suitable for strong acid and alkali, preventing corrosion.

PTFE Lined Butterfly Valve: Suitable for highly corrosive chemicals such as concentrated sulfuric acid and hydrofluoric acid.

Double Offset or Triple Offset Butterfly Valve: Suitable for high temperature or high pressure corrosive media, extending service life.

Sealing Material: PTFE, EPDM, or other chemical resistant materials to ensure no leakage, no pollution.

Valve Body Material: Stainless steel, alloy steel, or plastic (PFA, PVDF lining) for superior corrosion resistance.

Other considerations:

Select appropriate valve body and sealing materials based on the specific chemical medium to ensure long-term durability.

Pneumatic or electric actuators can be used for automated control.

Summary

| Application | Recommended Valve Type | Sealing Material | Valve Body Material | Key Considerations |

|---|---|---|---|---|

| Water Supply | Wafer, Lug, Flanged Butterfly Valve | Soft seal (EPDM, NBR) | Ductile iron, stainless steel, carbon steel | Drinking water standards, water hammer prevention |

| Oil Transport | Lug, Double Flanged, Metal Seated Butterfly Valve | NBR or metal sealing | Carbon steel, stainless steel | Fire safety certification, high-pressure resistance |

| Gas Transport | Triple Offset Metal Seated, Lug, Double Flanged Butterfly Valve | Metal sealing, PTFE | Carbon steel, stainless steel | Zero leakage, explosion-proof design |

| Chemical Pipelines | Fully Lined, PTFE Lined, Double/Triple Offset Butterfly Valve | PTFE, EPDM | Stainless steel, alloy steel, PFA/PVDF lining | Corrosion resistance, automated control options |

Choosing the right butterfly valve depends on the medium, pressure, temperature, and installation environment of the pipeline to ensure safe, stable, and long-term operation.

Butterfly Valve Installation

Proper installation of a butterfly valve is essential for optimal performance and longevity. Below are step-by-step instructions for installing different types of butterfly valves:

1,Wafer Butterfly Valve Installation (Wafer butterfly valves are installed between two flanges using bolts and do not have threaded holes on the valve body.)

Tools & Materials Needed:

Wafer butterfly valve, Pipe flanges, Bolts, nuts, and washers, Gasket (if required), Wrench or spanner, Torque wrench, Pipe alignment tool

Installation Steps:

Check the Valve and Pipeline:Make sure the valve and pipeline are clean, free of debris, and undamaged.Ensure the valve size matches the pipeline size.

Partially Open the Butterfly Valve:Open the disc slightly (about 10% open) to prevent damage during installation.

Align the Flanges and Valve:Position the valve between the two pipeline flanges.Use a pipe alignment tool or clamps to hold the valve in place.

Insert the Bolts:Pass the bolts through the flange holes and loosely tighten the nuts to hold the valve in place.

Center the Valve:Make sure the butterfly valve is centered properly before fully tightening the bolts.The valve disc should not touch the pipeline when opening or closing.

Tighten the Bolts Evenly:Use a torque wrench to tighten the bolts in a crisscross pattern to ensure even pressure.

Check Valve Operation:Fully open and close the valve to ensure smooth operation and proper sealing.

Final Tightening and Testing:Once confirmed, fully tighten the bolts to the recommended torque.Perform a pressure test to check for leaks.

Wafer butterfly valve installation

2,Lug Butterfly Valve Installation (Lug butterfly valves have threaded holes in the valve body, allowing direct bolting to one or both pipeline flanges.)

Tools & Materials Needed:Lug butterfly valve, Pipe flanges, Bolts and washers, Wrench or spanner, Torque wrench

Installation Steps:

Inspect the Valve and Pipeline:Make sure both the valve and pipeline are clean and undamaged.Check that the valve size matches the pipe size.

Position the Valve:Align the valve with the flange holes.

Attach One Side First:If you are replacing a valve without removing the entire pipeline, bolt one flange to the valve body first.Hand-tighten the bolts.

Align the Second Flange:If you are connecting both sides, align the second flange with the valve.Insert the bolts into the threaded holes on the valve body.

Evenly Tighten the Bolts:Use a crisscross pattern to evenly tighten the bolts with a torque wrench.

Check the Valve Operation:Slowly open and close the valve to ensure smooth operation.

Final Torque and Pressure Test:Fully tighten the bolts to the required torque and conduct a pressure test to check for leaks.

Lug butterfly valve installation

3,Flanged Butterfly Valve Installation (Flanged butterfly valves have integral flanges on the valve body and are bolted directly between pipe flanges.)

Tools & Materials Needed: Flanged butterfly valve, Pipe flanges, Gaskets, Bolts, nuts, and washers, Wrench or spanner, Torque wrench

Installation Steps:

Inspect the Valve and Pipeline:Make sure the pipeline and valve are clean and free of dirt and damage.Confirm the valve size matches the pipeline size.

Install the Gaskets:Place gaskets between the valve flanges and pipe flanges.

Align the Valve with the Pipeline:Position the valve so the bolt holes align with the pipeline flanges.

Insert and Tighten the Bolts:Insert the bolts and loosely tighten them to hold the valve in place.Make sure the valve is properly centered.

Evenly Tighten the Bolts:Use a crisscross tightening pattern with a torque wrench to apply even pressure.

Check Valve Operation:Open and close the valve to ensure smooth movement and proper sealing.

Final Tightening and Testing:Fully tighten the bolts to the required torque.Perform a pressure test to check for leaks.

Flanged butterfly valve installation

4,Grooved Butterfly Valve Installation (Grooved butterfly valves are installed with grooved couplings instead of bolted flanges, allowing for quick assembly.)

Tools & Materials Needed: Grooved butterfly valve, Grooved pipe ends, Grooved couplings, Gasket (if required), Pipe alignment tool, Torque wrench

Installation Steps:

Inspect the Valve and Pipe Ends:Make sure the grooved ends are clean, undamaged, and properly prepared.

Install the Gasket (if required):If the grooved coupling requires a gasket, place it inside the coupling.

Position the Valve:Insert the valve between the grooved pipe ends.

Attach the Grooved Couplings:Slide the grooved couplings over the pipe ends and valve.

Tighten the Coupling Bolts: Use a torque wrench to tighten the coupling bolts evenly.

Check Valve Operation: Open and close the valve to ensure smooth movement.

Final Tightening and Testing: Make sure all bolts are secure and perform a pressure test to check for leaks.

Grooved butterfly valve installation

Important Installation Tips for All Butterfly Valves:

Do NOT fully close the disc before installation to prevent damage.

Always use a crisscross bolt tightening pattern to ensure even pressure.

Check for pipeline misalignment before installing the valve to avoid stress on the valve body.

Perform leak and function tests after installation to ensure proper operation.

Butterfly Valves Problems, causes, and solutions

1, Water Systems

Common Problems:

Dripping: Water leaks around the valve.

Cause: The seal is old or damaged, or the valve was not installed correctly.

Prevention and Solution: Regularly inspect and replace the seal, and make sure the valve is installed correctly.

Hard to Turn: The valve is hard to turn.

Cause: The valve has not been turned for a long time, or there is dirt or corrosion on the valve.

Prevention and Solution: Regularly turn the valve, and clean it to prevent dirt from building up.

Sticking or Not Closing All the Way: The valve does not close all the way.

Cause: The valve parts are damaged, or the rubber seal is old.

Prevention and Solution: Regularly inspect and replace the rubber seal and valve parts.

Stuff Blocking the Valve: Something is blocking the valve.

Cause: The water is dirty, and you do not have a filter before the valve.

Prevention and Solution: Install a filter before the valve, and clean it regularly.

Corrosion: The metal valve parts are corroding because of the impurities in the water.

Cause: The metal valve parts have been in contact with oxygen or acidic water for a long time.

Prevention and Solution: Use a valve made of stainless steel or other materials that resist corrosion, and regularly inspect the valve.

2. Oil Systems

Common Problems:

Dripping: Oil leaks around the valve, which can be dangerous.

Cause: The seal is bad, or the valve is old.

Prevention and Solution: Use seals that resist oil, and regularly inspect and replace the seals.

Hard to Turn: The valve is hard to turn.

Cause: There is oil buildup or dirt in the valve.

Prevention and Solution: Regularly clean the valve, and inspect the lubrication system.

Sticking: The valve sticks because there is sticky oil buildup.

Cause: There are oil deposits in the valve, or you have not turned the valve for a long time.

Prevention and Solution: Regularly turn the valve, make sure it is well lubricated, and clean it.

Deformation: The valve body deforms under high pressure.

Cause: The valve is under too much pressure and heat.

Prevention and Solution: Use materials that resist high pressure and heat, and regularly check the valve.

Corrosion: The valve parts are corroding because of the oil.

Cause: The oil has sulfur, acid, and other things that corrode the valve parts.

Prevention and Solution: Use materials that resist corrosion, and regularly check the valve.

3. Gas Systems

Common Problems:

Dripping: Gas leaks out of the valve, which is dangerous.

Cause: The seal is bad, or the valve is old.

Prevention and Solution: Use butterfly valves with metal seals, and regularly check the seals.

Hard to Turn: The valve is hard to open or close.

Cause: You do not turn the valve very often, or the seal is damaged.

Prevention and Solution: Regularly turn the valve, make sure it is well lubricated, and check the seal.

Seal Failure: The gas leaks because the seal fails when the pressure changes.

Cause: The gas pressure changes, or the seal material is not right.

Prevention and Solution: Use seals that are made for high pressure and high temperature, and regularly check the seals.

Corrosion and Scaling: The gas has water or acid in it, which can corrode the valve parts.

Cause: The gas has acid in it, like H2S.

Prevention and Solution: Use materials that resist corrosion, like stainless steel, and regularly clean and check the valve.

Thermal Expansion: The valve material expands when it gets hot, which can affect how the valve works.

Cause: The temperature is too high, or the temperature changes too fast.

Prevention and Solution: Use materials that resist high temperatures, and regularly check the temperature and the valve.

4. Chemical Systems

Common Problems:

Corrosion: The valve parts are corroding because of the strong chemicals.

Cause: The valve has been in contact with strong acids, bases, or other chemicals.

Prevention and Solution: Use materials that resist corrosion, like valves lined with PTFE or made of alloy steel.

Dripping: The seal fails because the chemicals do not like the seal material.

Cause: The seal material is not right for the chemicals.

Prevention and Solution: Use seals that are made for the chemicals, and regularly inspect and replace the seals.

Sticking: The chemicals have solid particles or residue that make the valve stick.

Cause: The chemicals have solid particles or residue in them.

Prevention and Solution: Put a filter before the valve, and clean the valve regularly.

Damage: The chemicals make the valve material tired or crack.

Cause: The valve has been in contact with reactive chemicals, like strong acids or solvents.

Prevention and Solution: Use materials that resist the chemicals, like fluoropolymer linings or high alloy steels, and regularly check the valve.

Scaling and Deposits: The chemicals cause minerals to build up in the valve, which can affect the flow and how the valve works.

Cause: The chemicals evaporate or react to make solids in the valve.

Prevention and Solution: Clean the valve regularly, use materials and designs that resist scaling, and put coatings on the valve to reduce the deposits.

5. Seawater Systems

Common Problems:

Corrosion: The valve materials are corroding because they are in the seawater.

Cause: The valve has been in the salty water for a long time, and it is rusting and corroding.

Prevention and Solution: Use materials that resist seawater corrosion, like SS316L stainless steel, and put coatings on the valve to stop corrosion.

Scaling and Deposits: The seawater has minerals and organic matter in it that make deposits in the valve.

Cause: The seawater has calcium, magnesium, and other minerals in it.

Prevention and Solution: Clean the valve regularly, use materials and coatings that resist scaling, and put coatings on the valve to reduce the deposits.

Hard to Turn: The seawater makes the valve stick or hard to turn.

Cause: The salt and minerals build up in the valve, or the valve is corroded inside.

Prevention and Solution: Regularly turn the valve and clean it, use materials that resist corrosion, and put the right coatings on the valve.

Seal Failure: The seawater makes the seals go bad, and the valve leaks.

Cause: The seals go bad because they are in the saltwater all the time.

Prevention and Solution: Use seals that resist seawater, like Viton or PTFE, and regularly replace the seals.

Wear from Particles: The seawater has particles in it that wear on the valve surfaces.

Cause: The seawater has sand, silt, and other particles in it.

Prevention and Solution: Use designs that resist wear, and clean the valves regularly.

6. High-Temperature and High-Pressure Systems

Common Problems:

Dripping: The seals go bad because of the high temperature and pressure, and the valve leaks.

Cause: The seal material breaks down under extreme conditions.

Prevention and Solution: Use butterfly valves with metal seals, regularly check the seals, and use materials that are made for high temperature and high pressure.

Deformation: The valve parts deform because of the high pressure and heat.

Cause: The valve has been in high temperature and high pressure for a long time.

Prevention and Solution: Use materials that are made for high temperature and high pressure, like alloy steels.

Seal Failure: The seals are not good enough for the extreme conditions, and they go bad.

Cause: The seals are not made for the high temperature and pressure.

Prevention and Solution: Use seals that resist high temperature, like metal-to-metal seals, and regularly check the seals.

Hard to Turn: The high temperature makes the valve expand, and it is hard to turn.

Cause: The material expands because the temperature changes.

Prevention and Solution: Use materials that resist expanding when they get hot, and use the right lubricants for high temperature.

Scaling and Deposits: The high temperature makes minerals build up in the valve.

Cause: The high temperature makes the minerals evaporate or react to make solids in the valve.

Prevention and Solution: Clean the valve regularly, use materials that resist scaling, and put coatings on the valve to reduce the deposits.

If you keep up with maintenance and use the right materials, you can avoid most of these problems.

Butterfly valve VS gate valve

1, Butterfly valve and gate valve are both important parts of a pipeline to cut off fluid or gas, but butterfly valve has one more function compared to gate valve, that is, it can be used as a flow regulator, i.e. butterfly valve can be used to reduce the flow rate when it is not fully open.

2, Butterfly valve is through the rotation of the valve disc around the valve stem to achieve the opening and closing of the valve, while the gate valve is through the up and down movement of the valve disc driven by the valve stem to achieve the opening and closing of the valve, so the stroke of the butterfly valve is shorter and the opening and closing is more rapid.

3, in terms of design, the butterfly valve has a simpler construction, so the cost is lower compared to the gate valve and has a price advantage.

4, The butterfly valve’s valve disc is designed with a scraping function, so it is suitable for fluids and gases containing suspended particles. The butterfly valve disc and sealing ring are made of more diversified materials, such as viton and PTFE seals, which are resistant to corrosion and high temperatures, etc. If required, the disc and body of the butterfly valve can also be covered with rubber, which makes it suitable for corrosive and high & low temperature fluids and gases.

5, In terms of connection, butterfly valves are available in a variety of designs such as wafer type, lug type, groove type, butt-weld type and flange type, so that they can be flexibly selected according to the specific working conditions, especially when the installation space is small, compared to the gate valve, there are greater advantages

6, for larger size pipelines, butterfly valves are usually chosen, because the structural characteristics of gate or globe valves in large size pipelines determine that the valve will be very large, very heavy and high cost

What pressure can butterfly valve afford?

For resilient seated or metal seated , ductile iron body butterfly valves can withstand a maximum working pressure of 2.5 Mpa .

If higher pressures are required, then steel material and metal seated butterfly valves are required.