High Pressure Pipe Repair Clamp

High pressure repair clamp are specially designed for high pressure pipelines ,the max.pressure it can afford is 70 bar for big size pipe ,200 bar for small size pipe. Judberd high pressure repair clamp have high reliability for pressurized pipeline repair. Can be quickly and securely installed without full network shutdown. Have Long-term corrosion protection through internal coating and high-strength materials.

Specification

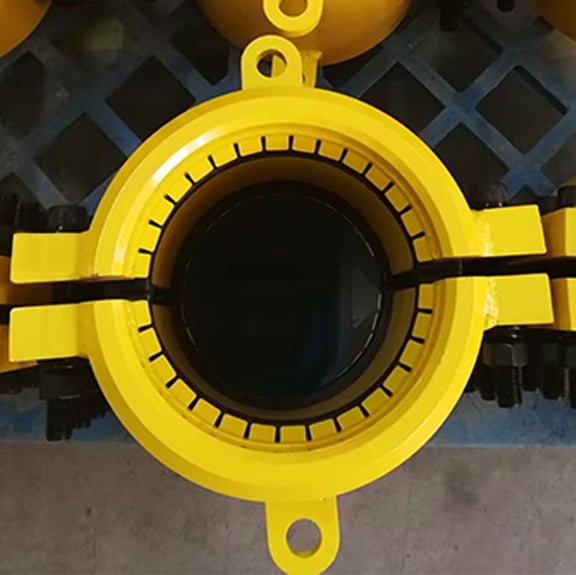

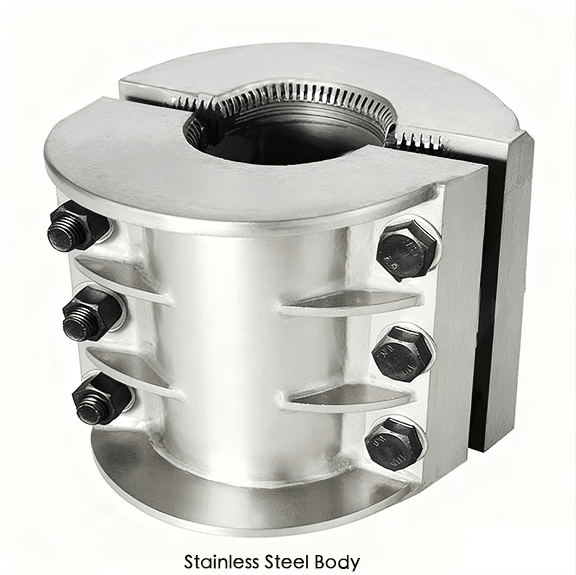

● Judberd has designed the shell type high pressure Repair Clamp in carbon steel to meet the needs of high pressure pipe repair. the surface can be sprayed, painted with epoxy paint or with a corrosion protection coating of your choice depending on the material inside the pipe and the surroundings of the repair clamp.

● Our high-pressure repair clamp can withstand pressures of up to 200 bar for small size which is smaller than DN250, and up to 70 bar for large pipe sizes up to DN 1200, which is sufficient for most high-pressure pipe repairs. if the customer has a higher pressure pipe to be repaired, we can also design it to suit the actual working conditions.

●Standard: Designed per ASME section VIII DIV.1

● Single piece molded seal fixed in wedge lock grooves for each half of clamp for peripheral and lateral sealing.

● Easily replaceable seal without special tools or grinding needed.

● Seal length: Standard 5-inches (2- to 12-inches); 8-inches (from 14-to 24-inches)

● Buna-N, Teflon and silicon rubber optional seal materials.

● Temperature ranges from -20 deg C to 250 deg C.

● Pressure range from 0-2030 psi for small size and 0-1000 psi for bigger size.

●Hinge and rod assembly are provided as per client’s request.Lifting lugs are provided on clamp sizes 12-iches and larger for easy installation.Relief plug connection of 1/2-inch NPT.Heat insulating cord (parallel to seal) facilitates welding of sleeves to pipe and protects seal if clients require.

●Hydro testing at 1.5 times of design pressures at factory prior to shipping.

●High temperature and low temperature applications are available. Consult our factory representative

Options:Special seal length available: Up to 30-inches with an overall length up to 40-inches.Medium-yield steel, high-yield steel and other material available upon request.Normally the clamps material is carbon steel.Bolts and nuts materials are as per client’s request.

Anti-Corrosion Coating to Clamp body and bolts and nuts are available, as per client’s request

● Application Permanent or temporary pipe leak repair for hydrocarbon, steam, petrochemical, oil and cross-country pipelines.

Product instruction

pressure test video for high pressure pipe repair clamp

Mill test report for high pressure pipe repair clamp

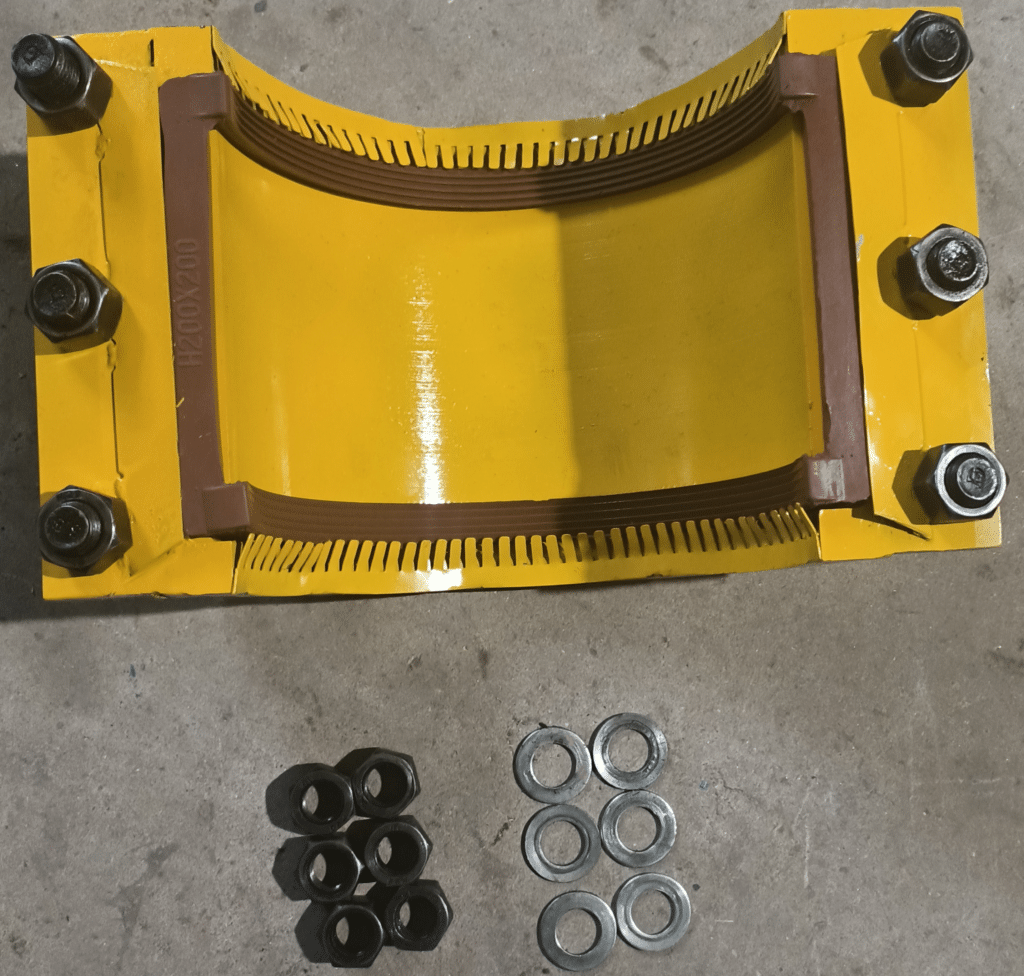

Products Details( take below product as example):

8″ straight pipe clamp split sleeve type, Design Pressure: 1000 psi;

Material Seals: Viton; Clamp body :ASTM A516 GR.70; Clamp lug :ASTM A516 GR.70. ; Clamp Bolts: ASTM A193 GR. B7 , Clamp Nuts: ASTM A194 GR 2H

| Test Item | Technical request | test result |

|---|---|---|

| Physical appearance | No dirty,with PTFE coating | ok |

| PTFE Coating to clamp body (warranty 5 years) | Thickness is 0.08mm to 0.1mm | ok |

| PTFE Coating to bolts and nuts (warranty 5 years) | Thickness is 0.02mm to 0.03mm | ok |

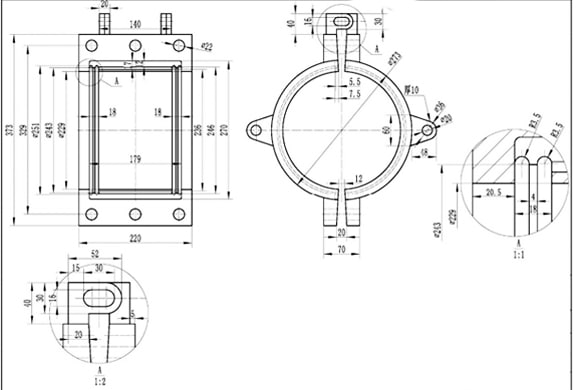

| Dimensions | As per below drawings (Tolerance ±1mm) | ok |

| Clamp body material | ASTM A516 GR.70 | ok |

| Bolts material | ASTM A193 GR. B7 | ok |

| Nuts material | ASTM A194 GR 2H | ok |

| Viton Seals | Fluoro Rubber | ok |

| NDT to all the welding lines | conducted by ultrasonic testing | ok |

| Hydraulic Test | 1.30 time of design pressure(1.3*1000PSI=1300 PSI), Keep test pressure at least 2 hours, no deformation, no leak | ok |

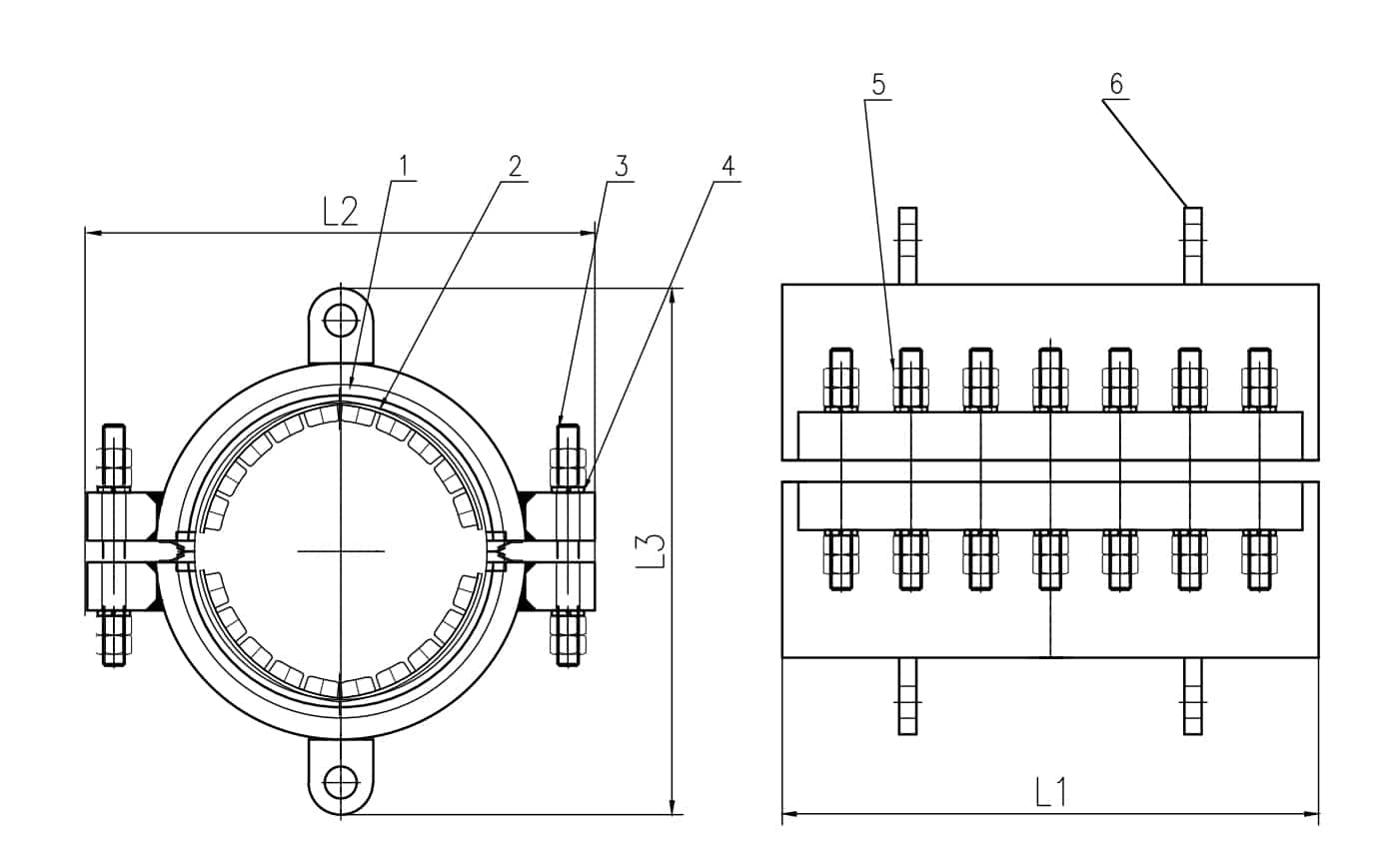

Drawing

Material

| Part No. | Name | Material |

|---|---|---|

| 1 | Body | ASTM A216 Grade WCB |

| 2 | Seal | NBR |

| 3 | Bolt | ASTM A193 B7 anticorrosion treatment:galvanization |

| 4 | Washer | galvanized carbon steel |

| 5 | Nut | ASTM A194 2H anticorrosion treatment:galvanization |

| 6 | Lifting Lug | ASTM A216 Grade WCB |

Dimensions

(unit mm)

| Size | Outer diameter of pipe(mm) | L1 | L2 | L3 | Number of Bolts (per side) |

|---|---|---|---|---|---|

| 8" | 203 | 350 | 346 | 356 | 5 |

| 10" | 254 | 350 | 397 | 407 | 5 |

| 12" | 305 | 350 | 511 | 521 | 5 |

| 16" | 406 | 450 | 612 | 622 | 6 |

| 20" | 508 | 500 | 714 | 724 | 7 |

| 28" | 711 | 550 | 931 | 951 | 8 |

1.Design calculation reference is according to ASME BPVC.VIII.1-2023 Division 1

2.Body with FBE coating no less than 250μm

3.The water pressure test 100bar (5 minutes)

4.Connection for steel pipe, suitable for gas

5.Temperature:15℃ to 60℃

6.Maximum Allowable Pressure:10 MPa (100 bar)

Other size and length is available upon request

Please note dimension may vary at our discretion

Drawing

Material

| Sr.No. | Name | Material |

|---|---|---|

| 1 | Body | Carbon Steel |

| 2 | Gasket | EPDM/NBR |

| 3 | Bolts,Nuts and Washers | Carbon steel or Stainless Steel |

| 4 | Plug | Carbon steel or Stainless Steel |

Dimensions

(unit mm)

| Pipe Size | A | D | C | Working Pressure PN bar |

|---|---|---|---|---|

| 38 | 73 | 139 | 228 | 140 |

| 50 | 79 | 146 | 228 | 140 |

| 63 | 85 | 133 | 215 | 140 |

| 76 | 101 | 133 | 215 | 140 |

| 101 | 127 | 133 | 215 | 140 |

| 152 | 180 | 133 | 228 | 140 |

| 203 | 231 | 133 | 254 | 140 |

| 254 | 285 | 139 | 266 | 140 |

| 304 | 336 | 139 | 266 | 100 |

| 355 | 368 | 203 | 355 | 100 |

| 406 | 419 | 203 | 355 | 100 |

| 457 | 469 | 203 | 355 | 100 |

| 508 | 520 | 203 | 355 | 64 |

| 558 | 571 | 203 | 355 | 64 |

| 609 | 622 | 203 | 355 | 64 |

| 660 | 673 | 203 | 355 | 64 |

| 711 | 723 | 203 | 355 | 64 |

| 762 | 774 | 203 | 355 | 64 |

| 812 | 825 | 203 | 355 | 64 |

| 863 | 876 | 203 | 355 | 64 |

| 914 | 927 | 203 | 361 | 64 |

| 965 | 977 | 203 | 361 | 64 |

| 1016 | 1028 | 203 | 361 | 64 |

| 1066 | 1079 | 203 | 403 | 64 |

| 1219 | 1231 | 203 | 406 | 64 |

Other size and length is available upon request

Please note dimension may vary at our discretion

how to CHOOse high pressure pipe repair clamp?

High pressure pipe repair clamps are designed to quickly and reliably repair oil, gas, and high-pressure steel pipelines where the system pressure is above 25 bar.

Selecting the right clamp ensures long-term sealing, structural integrity, and safety under demanding working conditions.

1, Identify the Application Conditions

1. Medium

● Oil / Gas / Steam → Choose a clamp with a reinforced structure and high-temperature and oil-resistant gaskets.

● Water / Chemical Liquids → Choose materials resistant to corrosion like stainless steel or coated carbon steel.

2. Pressure

● For systems above 25 bar, the clamp rating should be ≥ 1.5 × system working pressure.

● Common classifications:

PN25–PN40 → Medium to high pressure

PN64–PN100 → High pressure

PN160+ → Ultra-high pressure

3. Temperature

● -20°C to +80°C → EPDM or NBR gasket

● Up to +120°C → Viton or PTFE gasket

● Ensure the gasket is compatible with the medium in the pipeline.

2, Confirm Pipe Details

1. Material

● Carbon steel, alloy steel, stainless steel, ductile iron, PVC, etc.

● Each requires different tightening torque and clamping force.

2. Dimensions

● Provide Outer Diameter (OD) and Wall Thickness (WT) .

● The clamp must cover the damaged area + at least 50 mm on each side.

3. Surface

● The surface should be clean, smooth, and free of weld protrusions or rust to ensure a proper seal.

3, Identify the Type of Damage

| Damage | Clamp |

|---|---|

| Small hole or pinhole leak | Single-section high pressure clamp |

| Linear crack | Double-section clamp |

| Circumferential crack | Full wrap reinforced clamp |

| Weld seam leakage | Wide-body high pressure clamp |

4, Select Proper Materials and Structure

Body

_

● SS304 / SS316 (ASTM A240) → Corrosion resistant, suitable for oil and gas.

● Carbon Steel + FBE / Hot Zinc Coating → Cost-effective for temporary repair.

● Super Duplex 2507 → For marine or acidic conditions.

Bolts & Nuts

_

● Grade 8.8 / 10.9 Zinc-Plated Steel → For medium pressure.

● A2-70 / A4-80 Stainless Steel → For corrosive environments.

● PTFE or MoS₂ coated bolts → Prevent seizing during tightening.

Sealing Gasket

_

● EPDM → Water

● NBR → Oil

● Viton → High temperature or oil-gas mixture

● PTFE → Chemicals or corrosive liquids

5, Determine the Structural Strength and Coverage

● The minimum coverage length = damage length + 100 mm.

● For pressures > 40 bar, use thick body and double-bolt-row design.

● For DN300 and above, use reinforced ribs or inner support rings.

● Manufacturers like Judberd can perform FEA analysis to ensure pressure and sealing performance.

6, Information Required for Quotation or Selection

| Parameter | Information Required from Customer |

|---|---|

| Medium | Oil / Gas / Water |

| Pressure | ____ bar |

| Outer Diameter (OD) | ____ mm |

| Wall Thickness (WT) | ____ mm |

| Type and Length of Damage | ____ |

| Material | ____ |

| Temperature | ____ °C |

| Location | Aboveground / Underground / Offshore |

| Permanent or Temporary Repair | Permanent / Temporary |

Expert Tip

For critical oil & gas lines, always choose clamps:

● Tested at 1.5× working pressure,

● With reinforced body and high-performance gasket,

● Backed by certified manufacturer FEA verification.

Judberd provides custom-engineered high-pressure repair clamps tailored for oil, gas, and industrial pipeline systems worldwide.

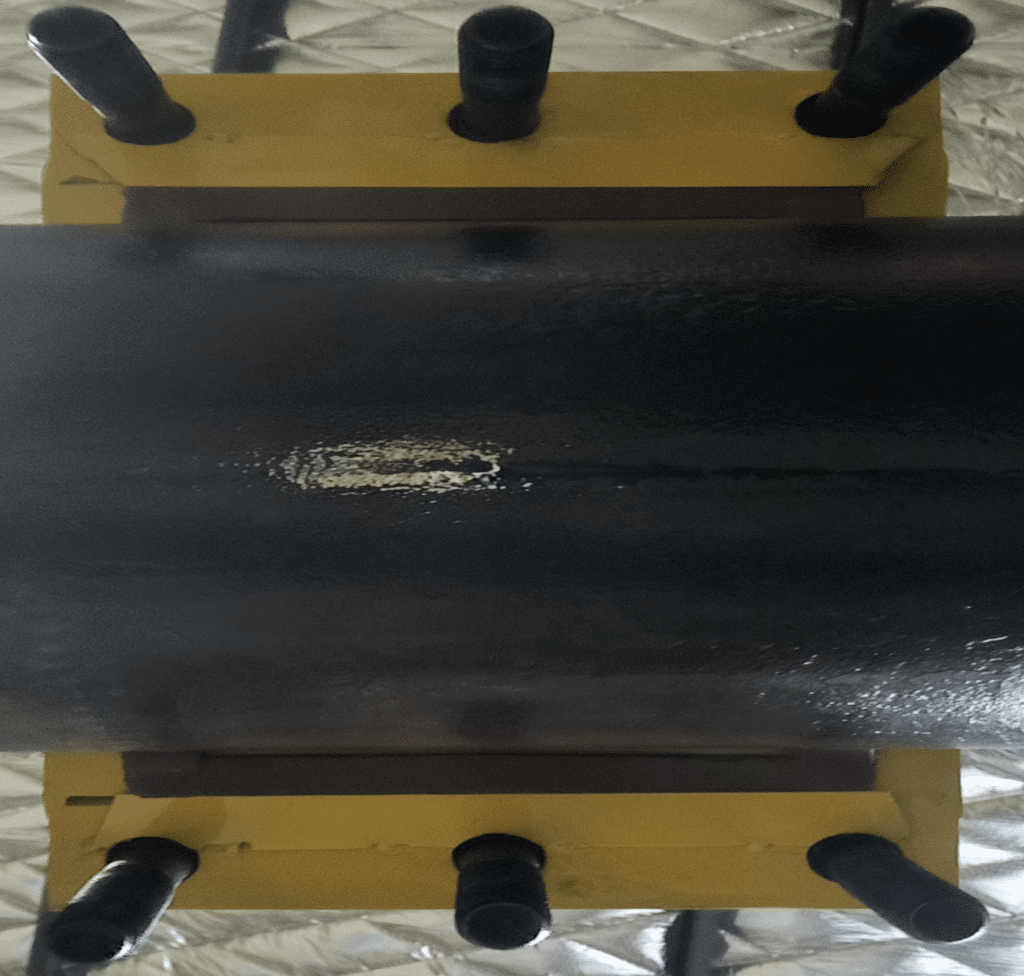

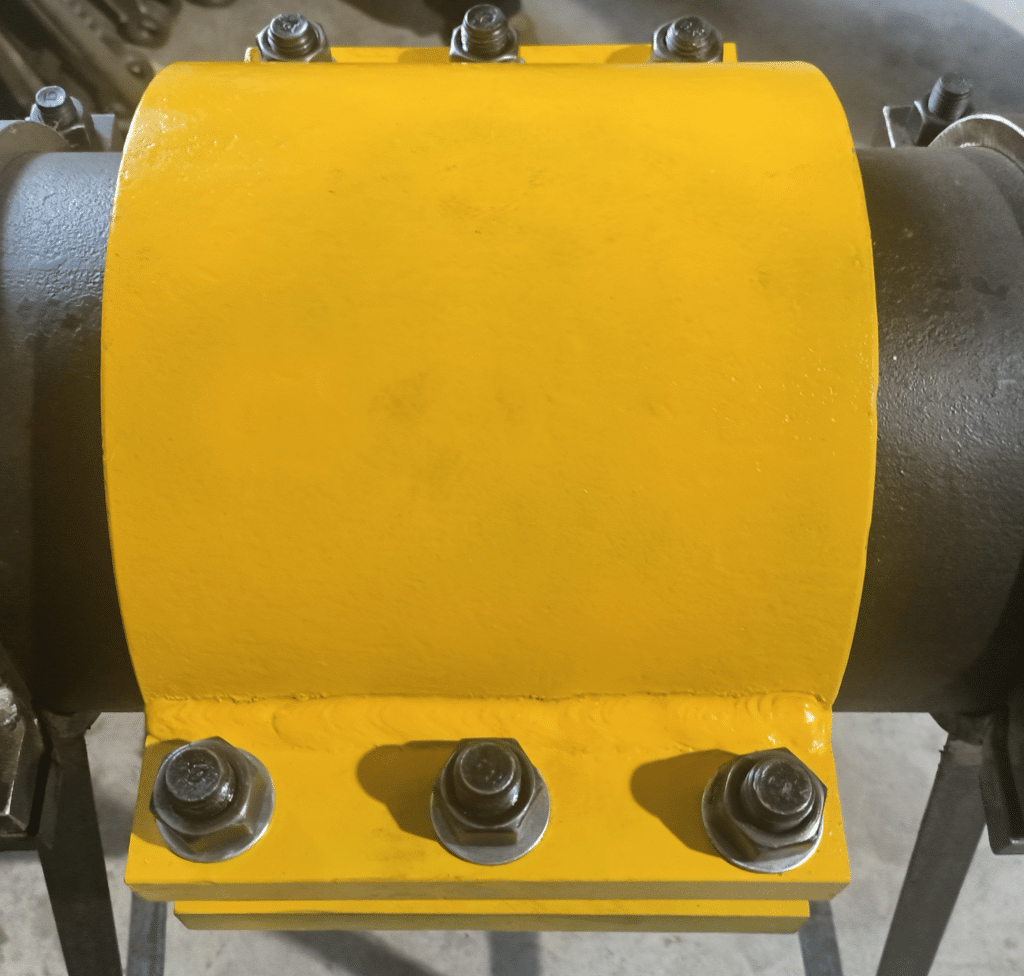

how to assemble high pressure pipe repair clamp?

01

Confirm the outer diameter of the pipe and select the right repair clamp.

02

Clean the surface of the pipe before installation.

03

Confirm the construction environment and wear good safety protection tools.

04

Prepare the installation tools and keep the pipeline free of pressure to avoid injury to worker.

05

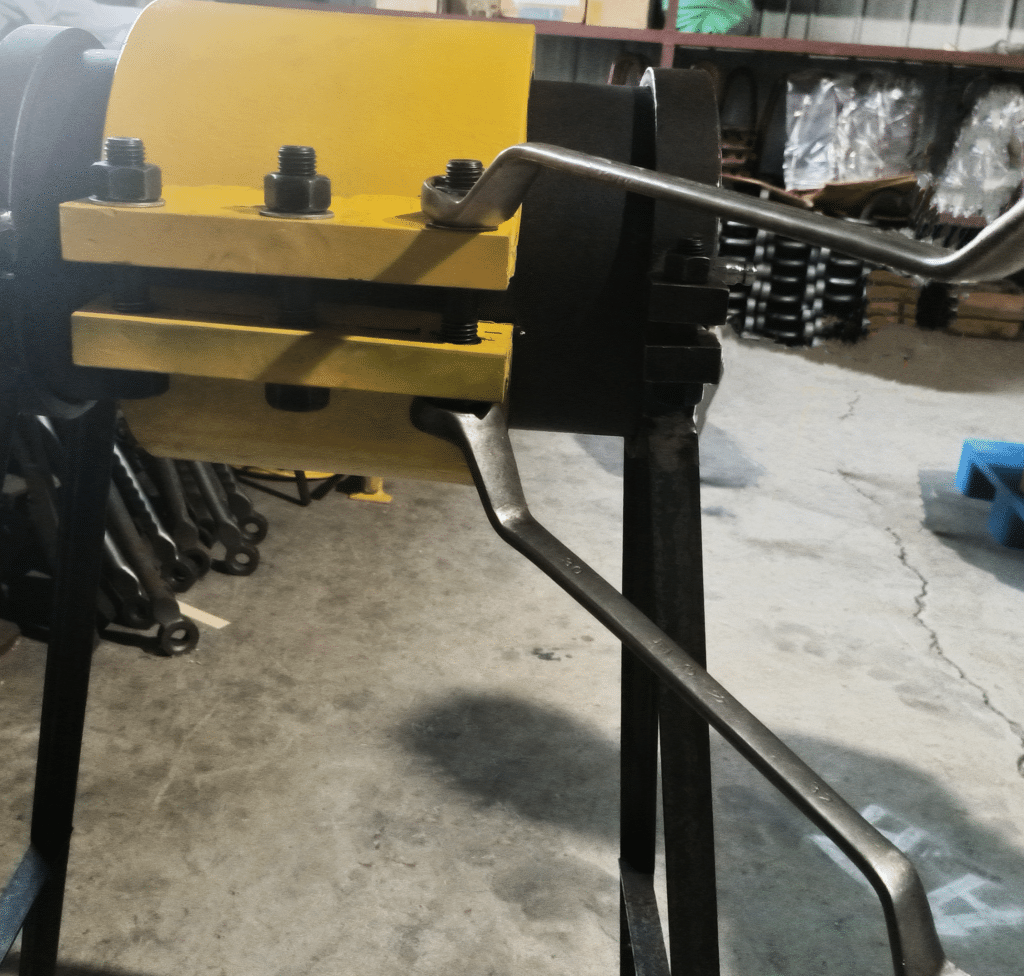

Open the repair clamp.

06

Place lower piece of the repair clamp onto the position of the pipe to be repaired. note that the leak point must be within the seal ring.

07

Install upper half piece of repair clamp and tighten the bolts.

08

Install according to the torque value recommended on our high pressure repair clamp manual. if a hydraulic spanner is not available during installation, an extension pole spanner can be used to achieve the strongest preload.