Dismantling Joint Feature

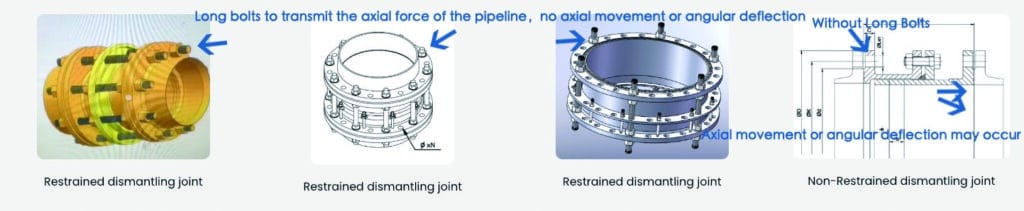

The most commonly used dismantling joint is the rigid type dismantling joint, non rigid dismantling joint does not have long tie rods which go through the whole dismantling joint, so when the pipeline have movement force because of the vibration of the ground, thermal expansion and contraction, because there is no long tie rods to support the fixation, the movement force will push the long part of the dismantling joint to move or deflect relative to the sealing rubber ring, then it is easy to cause leakage or even sealing rubber ring failure.

Nowadays, the commonly used dismantling joints are heavy duty dismantling joint and light duty dismantling joint, For the heavy duty dismantling joint you need to tight the nuts of the long tie rods (as below part5) to press the gland (as below part3) for the sealing ring to be pressed.

The light duty dismantling joint is operated independently by using a separate small bolt (part 5 below) to press the small flange (part 3 below) to compress the sealing ring to seal the joint.

At the same time, because there are small bolts to press the sealing ring, only 25% of the number of long tie rods (not less than 4 numbers) is needed to withstand the required pressure, so the cost is cheaper compared to heavy duty dismantling joints, but heavy duty dismantling joint can afford bigger axial force and higher pressure compared to light duty type.

HEAVY DUTY DISMANTLING JOINT

LIGHT DUTY DISMANTLING JOINT