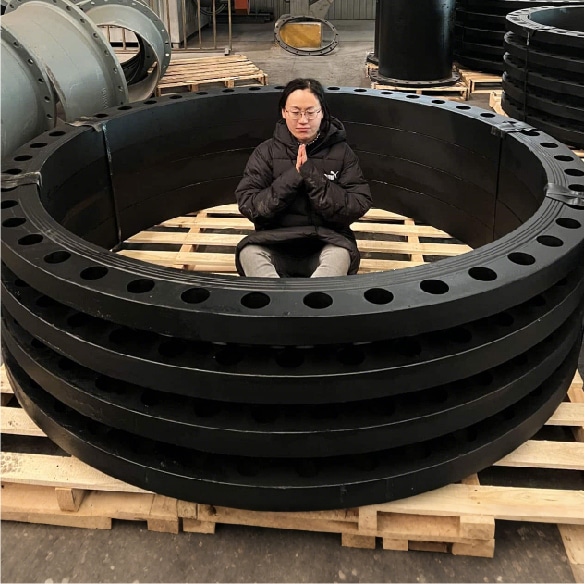

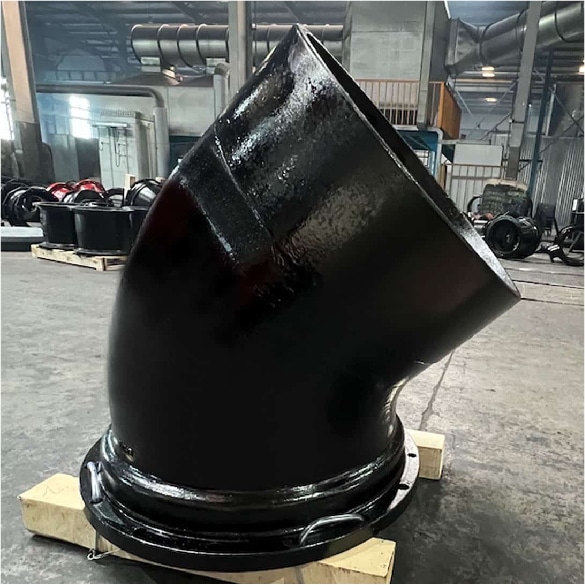

DUCTILE IRON PIPE FITTING MANUFACTURER

Ductile pipe fittings is the abbreviation of ductile iron pipe fittings , they are components used in piping systems to connect, divert, or otherwise manage the flow of fluids (usually water or sewage) through ductile iron pipes. These fittings are made from ductile iron, a type of cast iron known for its improved strength, flexibility, and impact resistance compared to traditional cast iron.

Judberd is a chinese manufacturer for ductile pipe fittings, our ductile iron fittings are classified as EN545/ISO2531 ductile iron fittings for water supply and irrigation, AWWA C110 and AWWA C153 ductile iron fittings for water supply and irrigation, EN598 ductile iron fittings for sewage and AS/NZS 2280 ductile iron fittings for water supply and irrigation in Australia, new Zealand and Fiji , EN12842 ductile iron fittings for PVC pipe and EN545/ISO2531 loose flange ductile iron fittings. Judberd is specially competitive for MJ fittings, also called mechanical joint fittings. Details as below

EN545/ ISO2531 DUCTILE IRON PIPE FITTING

Judberd can produce ductile iron pipe fittings include but not limit to below type, if you have enquiry sheet, welcome you contact judberd.

AWWA C110 ductile iron pipe fitting

Judberd can produce all ductile iron pipe fittings according to AWWA C110,

include but not limit to below type, if you have enquiry sheet, welcome you contact judberd.

CONCENTRIC AND

ECCENTRIC REDUCERS

90℃ REDUCING BENDS

90° LONG RADIUS BEND

TEE

CUSTOM DUCTILE IRON PIPE FITTING

Judberd’s professional R&D team can design and customize pipe fittings based on your engineering requirements.

Contact Judberd to get started on your custom design.

MORE PIPE FITTINGS AS BELOW IN OUR CATALOGUES

DUCTILE IRON PIPE FITTINGS CATALOG

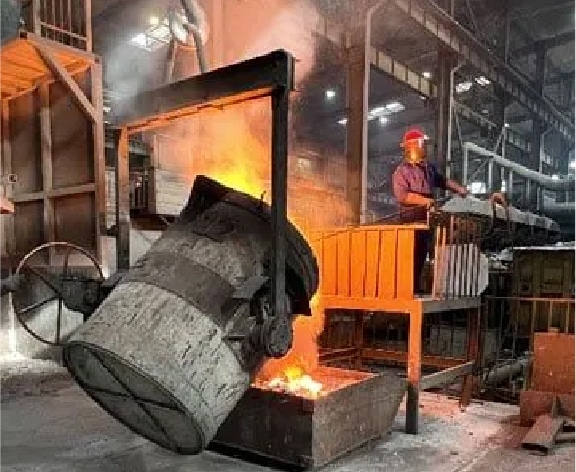

PRODUCTION PROCESS

Judberd have 2 types production process,

Vacuum lost foam casting and Static pressure line casting, their production processes are as below.

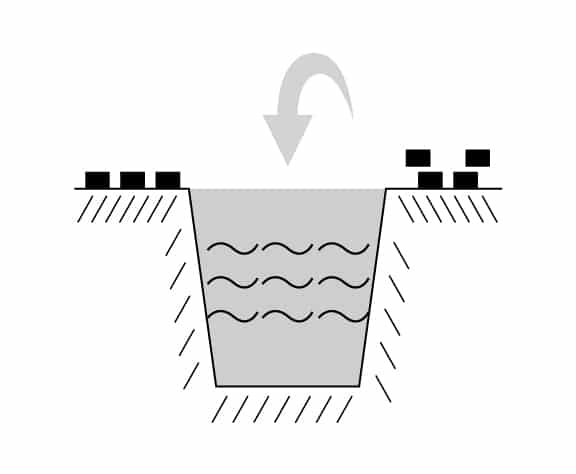

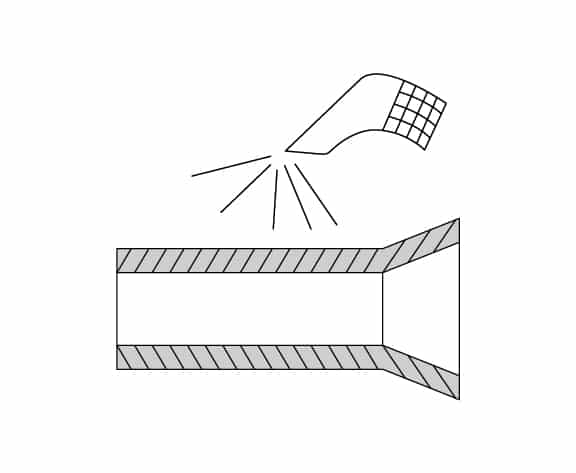

VACUUM LOST FOAM CASTING

Step 1

Preexpanding

Step 2

Modelling for lost foam moulds

Step 3

Stick pieces together to shape the lost foam for casting

Step 4

Lost foam moulds are ready

Step 5

Coating for lost foam moulds

Step 6

Dry the coated lost foam moulds

Step 7

Put the lost foam in the casting box

Step 8

Assemble the pouring channel

for the iron

Step 9

Cover lost foam moulds by sands

Step 10

Iron melting

Step 11

Nodular

Step 12

Remove the slag from the molten iron

Step 13

Pouring

Step 14

Release of parts

Step 15

Polishing

Step 16

Sand blast and machining

Step 17

Zinc spraying

Step 18

Pressure test

Step 19

Cement lining

Step 20

Apply asphalt coating

Step 21

Packing

After step 16

Sand blast and machining–FBE coating

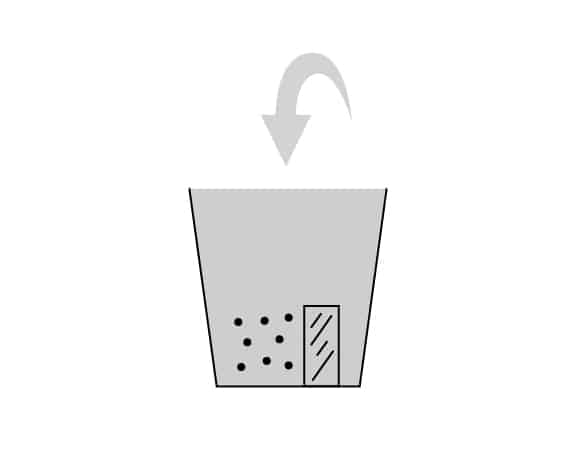

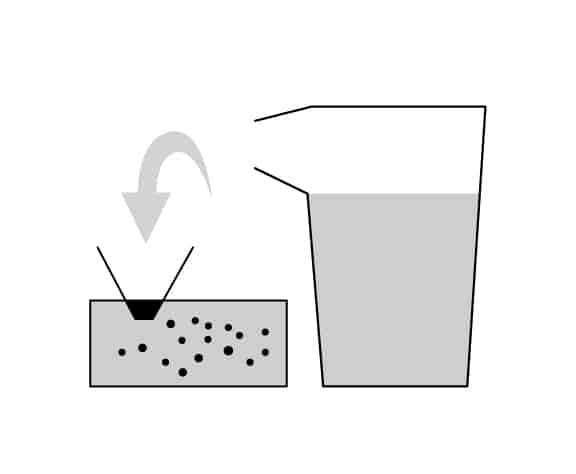

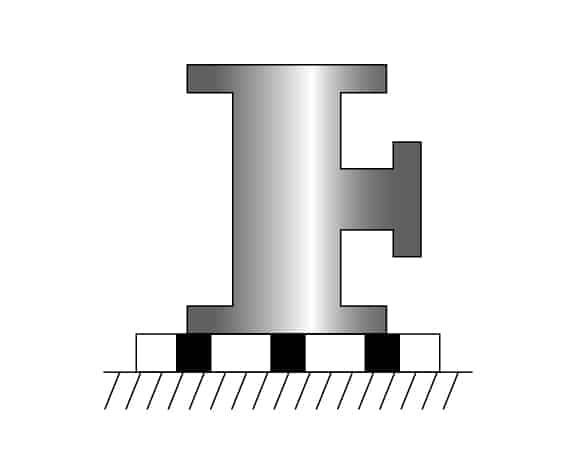

STATIC PRESSURE LINE CASTING

Step 1

Moulding sand preparation

Step 2

Injection molding

Step 3

Sand core preparation

Step 4

Bottom core closure

Step 5

Molten iron melting

Step 6

Nodular treatment

Step 7

Pouring

Step 8

Polish & Clean

Step 9

Sand blast and machining

Step 10

Zinc paint spray

Step 11

Hydraulic pressure test

Step 12

Cement lining

Step 13

Bitumen paint externally

Step 14

Package

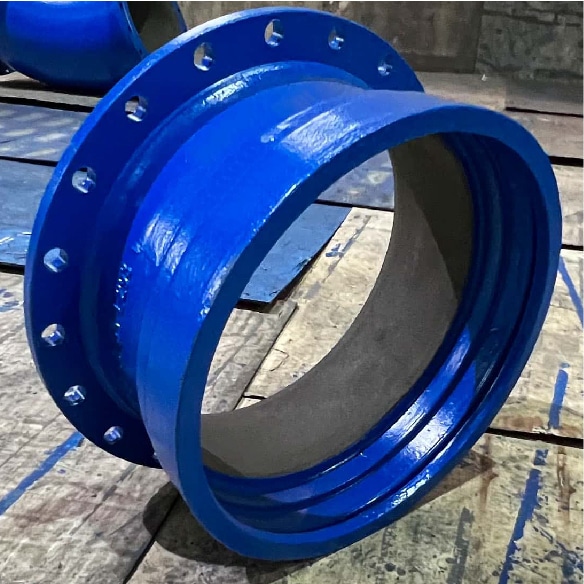

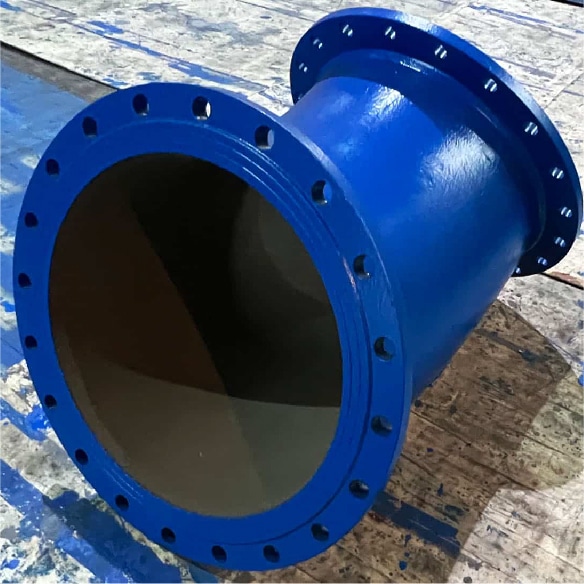

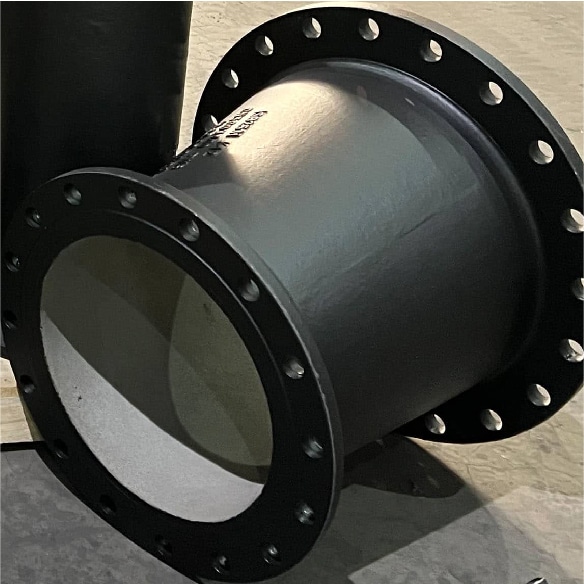

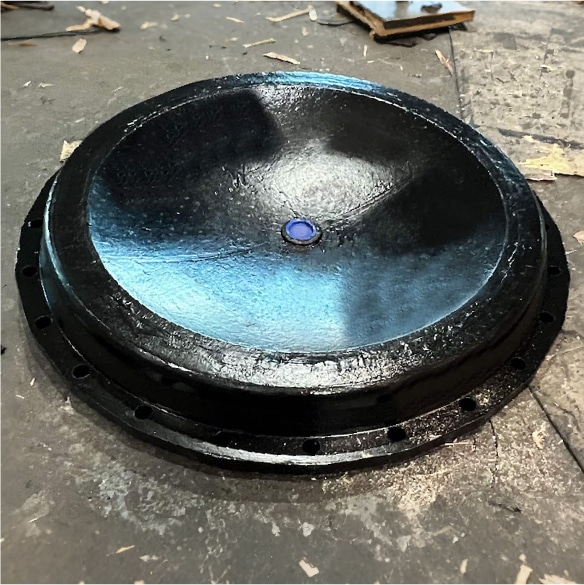

SURFACE COATING

We can do surface coating according to client project requirement,

below several types are for your reference.

FOR POTABLE WATER

Cement inside,zinc and

bitumen outside

FOR SEWAGE

High alumina cement lining inside,

red epoxy paint outside

FOR POTABLE WATER

Fusion bonded epoxy

inside and outside

FOR POTABLE WATER

Epoxy paint inside,

zinc and bitumen outside

FOR SEA WATER

Epdm lining inside,

anti-rust paint outside

FOR CHEMICAL FLUID

PTFE lining inside,

red epoxy paint outside

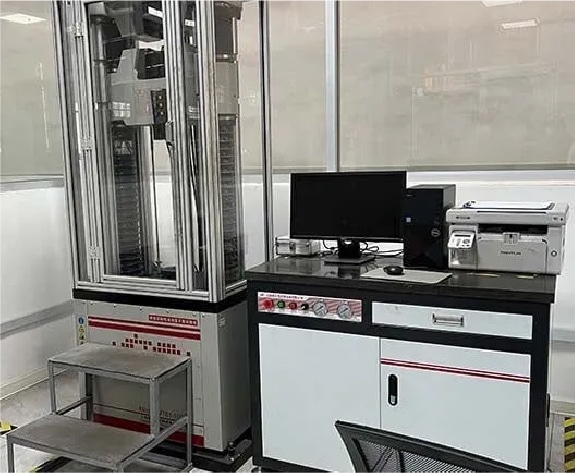

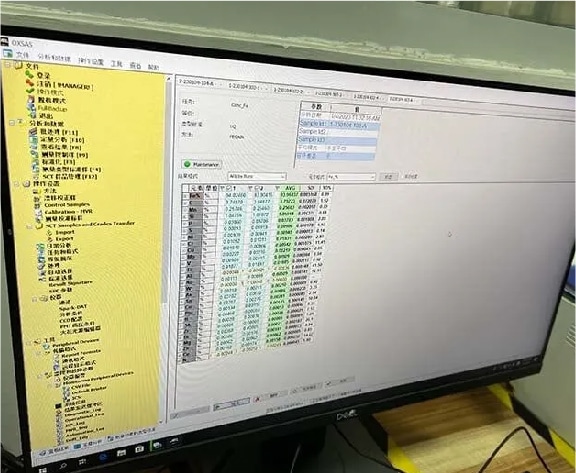

MATERIAL INSPECTION

1. Check the chemical composition of the iron with a pre-furnace analyser.

2. Adjust metal content in iron water by adding metal until the metal content is quanlified.

3. Machine test bars to standard sizes for tensile strength and elongation testing.

4. Use instrument to tensile test bars to test tensile strength and elongation.

5. Polishing samples for spectroscopy with a spectroscopy grinder.

6. Chemical Composition Testing By Spectrometer, 2 Tests Are Required To Ensure Accuracy.

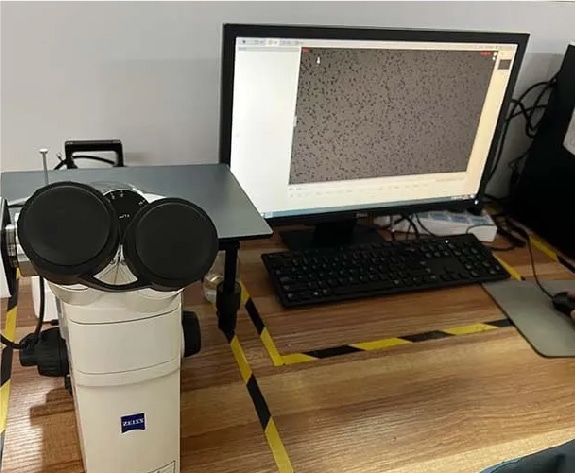

7. Polishing Of Samples For Metallographic Testing Using A Metallographic Specimen Grinding And Polishing Machine.

8. Metallographic testing to compare test results with standards to determine compliance.

INSPECTION

Judberd is a competitive manufacturer of ductile pipe fittings.

We have strict inspection procedures for product quality , below photos are for your reference

Hydrostatic Pressure Testing

Bitumen Thickness Inspection

Cement Thickness Inspection

Dimension Inspection

USE

Ductile iron pipe fittings are widely used for potable water, wastewater, and industrial applications,

but different pipeline have different requirement for ductile iron pipe fitting,

primarily in material selection, anti-corrosion coatings, connection methods, and pressure ratings.

1. POTABLE WATER SUPPLY

Applications Used in municipal water supply networks, water distribution pipelines, fire protection systems, and rural water supply.

Key Requirements is Material Safety, Must comply with drinking water safety standards such as ISO 2531, EN 545, AWWA C110/C153 to ensure no harmful substances are released.

● INTERNAL LINING (PREVENTS WATER CONTAMINATION)

Cement Mortar Lining – Commonly used, prevents water quality deterioration and provides some corrosion protection (ISO 4179).

Fusion Bonded Epoxy (FBE) Coating – Suitable for high-hygiene standard pipelines, offering superior corrosion resistance (AWWA C213, EN 14901).

● EXTERNAL PROTECTION COATING (CORROSION RESISTANCE IN VARIOUS ENVIRONMENTS)

Zinc Spray + Bitumen Paint – Basic protection (ISO 8179).

High-Performance Epoxy Coating – Suitable for highly corrosive environments such as coastal areas (AWWA C210, EN 545).

● PRESSURE RATINGS

Typically PN10, PN16, PN25, depending on water transmission pressure.

● CONNECTION METHODS

Socket Joint (Push-Fit Joint) – Common in municipal water networks, easy to install (EN 545).

Flange Joint – Used for large-diameter pipes or sections requiring disassembly and maintenance (ISO 7005).

2. WASTEWATER & SEWER SYSTEM

Applications Used in sewage networks, municipal drainage, and industrial wastewater treatment systems.

Key Requirements is Corrosion Resistance, Wastewater may contain acids, alkalis, and organic pollutants, requiring stronger anti-corrosion performance.

● INTERNAL LINING (CHEMICAL RESISTANCE)

Cement Mortar Lining – Suitable for general municipal sewage but has limited resistance to strong acids and alkalis (ISO 4179, EN 598).

High-Corrosion-Resistant Epoxy Coating – Used for industrial wastewater with chemical contaminants (AWWA C210, EN 14901).

Polyurethane Lining – Provides excellent abrasion resistance, suitable for wastewater containing sand, gravel, or particles (EN 15655).

● EXTERNAL PROTECTION COATING (CORROSION RESISTANCE IN VARIOUS ENVIRONMENTS)

Epoxy Powder Coating – Ideal for underground humid environments, enhances durability (AWWA C213, EN 598).

● PRESSURE RATINGS

Generally lower, typically PN6, PN10, PN16, as wastewater pipelines mainly rely on gravity flow and do not require high pressure.

● CONNECTION METHODS

Flexible Coupling – Recommended for areas with ground settlement, reducing pipeline stress.

Flange Joint – Used in pump stations and wastewater treatment plants requiring removable sections (ISO 7005).

3. INDUSTRIAL APPLICATIONS

Applications Used in industries such as oil, chemical processing, food manufacturing, metallurgy, and power plant cooling water systems.

Key Requirements is High-Temperature & Corrosion Resistance, Requires materials suited for chemical corrosion and high-temperature environments.

● INTERNAL LINING (FOR SPECIFIC MEDIA)

Rubber Lining – Ideal for strong acids and alkalis, used in chemical industries (ISO 1629).

Epoxy Coating – Suitable for industrial cooling water and general chemical transport (AWWA C210).

Ceramic Lining – Used for highly abrasive media such as slurry and mining applications.

PTFE (Polytetrafluoroethylene) Lining – Excellent chemical resistance, used for aggressive chemicals (ASTM D3307).

● EXTERNAL PROTECTION COATING (FOR EXTREME ENVIRONMENTS)

Hot-Dip Galvanized + Epoxy Coating – Suitable for high-humidity, high-salinity environments such as coastal industrial zones (ISO 1461).

PTFE Coating – Used for transporting organic solvents and highly corrosive chemicals (ASTM D3295).

● PRESSURE RATINGS

Industrial pipelines typically require higher pressure resistance, commonly PN16, PN25, PN40, or even higher depending on specific requirements.

● CONNECTION METHODS

Flange Joint – Ideal for high-pressure, high-temperature, and corrosive industrial pipelines (ISO 7005).

Threaded Joint – Suitable for small-diameter, high-pressure industrial piping.

The selection of ductile iron pipe fittings varies based on application needs.

For potable water, safety, hygiene, and pressure resistance are the primary concerns.

For wastewater, corrosion resistance and adaptability to chemical environments are critical.

For industrial applications, high-pressure and high-corrosion resistance requirements must be met with specialized linings and coatings.

CONNECTION METHODS

UNDERGROUND PIPING

CONNECTION METHODS

● Socket and Spigot Self-Anchoring Gasket Connection

This connection uses the socket and spigot ends of the pipe fitting, with a rubber gasket to seal the joint. The self-anchoring function of the gasket helps prevent movement of the pipeline under external pressure. During installation, the pipe ends are inserted into the socket of the fitting, ensuring the gasket is properly placed and seated to create a tight seal.It is used for most underground piping, especially where a good seal is required and the ground is not likely to settle. It is great for piping that is fixed in place or under heavy soil pressure.

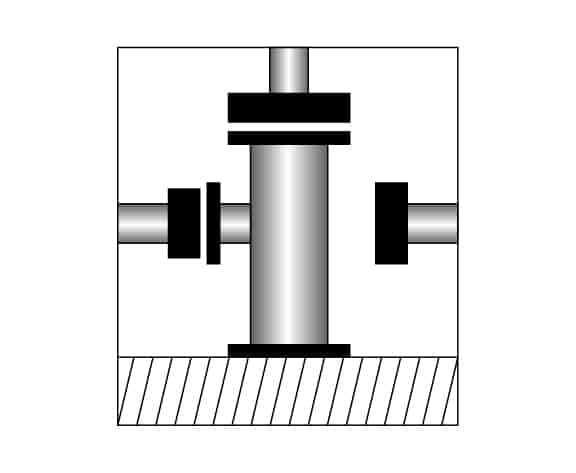

● Flanged Connection

Flanged connections involve attaching a flange to each pipe end and bolting them together. A gasket is usually used between the flanges to ensure a leak-proof seal.It is used for underground piping or piping that requires periodic maintenance or disassembly. Especially good for high-pressure piping or piping that connects to valves, pumps, or other equipment.

ABOVE-GROUND PIPING

CONNECTION METHODS

● Flexible Coupling Connection

Flexible couplings are used to connect pipes of different diameters or to compensate for slight misalignment or movement. The coupling wraps around the pipe joint with a flexible material (such as rubber or polyurethane) and is tightened with metal clamps, providing strong resistance to vibration and movement.It is used for above-ground piping that is subject to frequent vibration or slight movement, such as piping in industrial settings or under roadways where external forces may be present. It is also good for connecting pipes of different materials or sizes.

● Flanged Connection

Like underground systems, flanged connections can be used for above-ground piping, especially in high-pressure systems or when you need to take it apart.It is used for above-ground piping systems, especially when you need to take it apart frequently for maintenance, inspection, or replacement.

UNSTABLE GROUND

CONNECTION METHODS

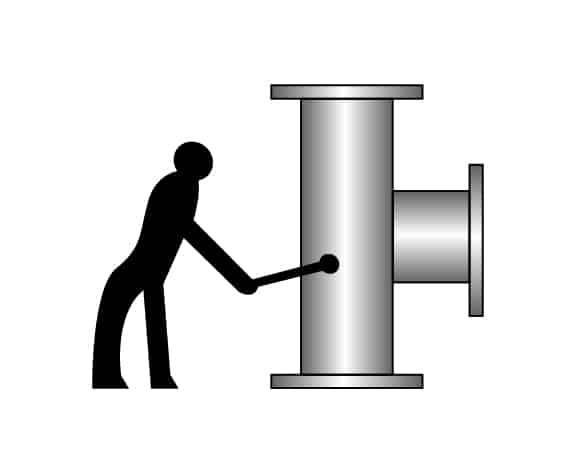

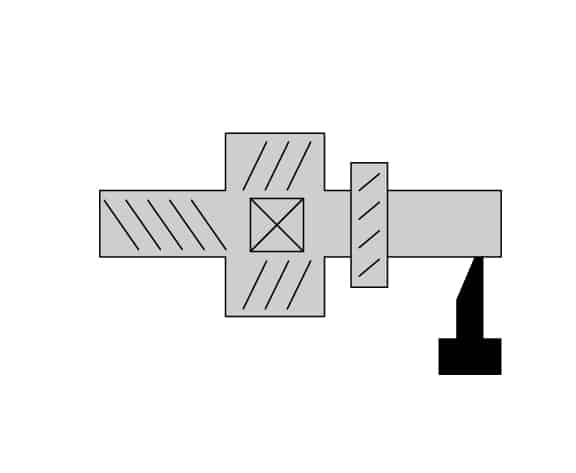

● Mechanical Joint Connection

This method uses a metal joint and rubber gasket to connect the pipe ends. The pressure can be adjusted with bolts to ensure a tight seal. Mechanical joints can connect pipes of different sizes and materials, giving you flexibility in your piping system.It is used for areas with unstable ground, such as soft soil, areas that settle, or where there is seismic activity or vibration. The flexibility and ability to move with the ground make it perfect for these conditions.

● Socket and Spigot Self-Anchoring Gasket Connection

When you are working in unstable ground, you must make sure the gasket is installed correctly to prevent leaks or the pipe from moving due to the ground. You may need extra support or a special design based on the ground conditions.It is used for areas with uneven ground or poor soil bearing capacity, particularly in soft or shifting soils.

SUMMARY OF CONNECTION METHODS FOR DIFFERENT ENVIRONMENTS

● Socket and Spigot Self-Anchoring Gasket Connection

Use for underground piping, large installations, and permanent installations. It seals well and is great for high-pressure applications.

● Flanged Connection

Use for above-ground piping or piping that you need to take apart frequently. Best for large diameter piping or high-pressure piping systems.

● Flexible Coupling Connection

Use for above-ground piping, especially in places where vibration or slight misalignment is common.

● Mechanical Joint Connection

Use for areas with unstable ground. It is flexible and resists movement, making it great for areas with seismic activity, settlement, or vibration.

Each connection method has its own unique advantages based on the installation environment.

The right choice ensures the stability and safety of your piping system over time.

Depending on the conditions where you are working, you need to choose the right connection method based on your use requirements,

the conditions where you are working, and your maintenance needs.

COMMON ISSUES, POSSIBLE CAUSES, AND SOLUTIONS FOR DUCTILE IRON PIPE FITTINGS

1. LEAKAGE AT THE JOINT

POSSIBLE CAUSES

● Improper Installation

If the fittings are not installed correctly, the seals may not be tight enough, leading to leaks.

● Damaged Gaskets or Seals

Gaskets or seals can wear out or get damaged during installation or because of environmental factors like excessive pressure or temperature.

● Incompatible Materials

Using the wrong gasket material or pipe material for the specific application (e.g., oil, gas, or water) may cause sealing issues.

SOLUTIONS

● Check the Installation

Make sure the pipe and fitting are lined up correctly and the gasket is seated properly in the groove. Tighten the bolts according to the manufacturer’s recommended torque settings.

● Inspect the Gasket

Replace any damaged or worn gaskets with new ones that are compatible with the medium being transported (e.g., EPDM for water, NBR for oil).

● Material Compatibility

Make sure the pipe, fitting, and gasket materials are suitable for the medium being transported and the environmental conditions.

2. CORROSION OF FITTING OR PIPE

POSSIBLE CAUSES

● Exposure to Harsh Environments

Ductile iron fittings can corrode when exposed to certain chemicals, saltwater, or high humidity.

● Inadequate Coating or Surface Protection

If the fittings are not properly coated or the coating wears off, they are more susceptible to corrosion.

SOLUTIONS

● Use Proper Coatings

For outdoor or coastal installations, make sure the fittings are coated with anti-corrosion treatments like polyester FBE powder for UV resistance or epoxy coatings for moisture resistance.

● Regular Inspection

Periodically check the fittings for signs of corrosion, especially in high-risk environments like marine or underground areas.

● Consider Material Upgrades

If corrosion continues to be a problem, think about switching to stainless steel (e.g., SS304, SS316) or adding additional corrosion-resistant coatings to the fittings.

3. MISALIGNMENT OR UNEVEN STRESS ON THE FITTINGS

POSSIBLE CAUSES

● Incorrect Alignment During Installation

When the pipes and fittings are not lined up correctly, uneven stress can be placed on the joints, leading to failure or deformation.

● Excessive Pressure

Too much pressure in the pipeline can cause the fittings to deform, leading to leaks or damage.

SOLUTIONS

● Proper Alignment

Make sure the pipe and fitting are lined up correctly before tightening. Use supports to hold the pipeline in place.

● Monitor Pressure

Check the operating pressure of the pipeline and make sure it does not exceed the rated pressure of the pipe fittings. Consider using pressure regulators or pressure relief valves if needed.

● Install Expansion Joints

For systems that experience temperature changes, installing expansion joints can help absorb the thermal expansion and prevent stress on the fittings.

4. CRACKING OR FRACTURING OF THE FITTINGS

POSSIBLE CAUSES

● Improper Handling During Installation

Dropping or hitting the fittings during handling can cause cracks, especially if the fittings are not properly supported.

● Impact from External Forces

External forces like heavy machinery or construction activities near the pipeline can result in cracking or fracturing.

● Excessive Temperature or Pressure Fluctuations

Significant changes in temperature or pressure can cause the ductile iron to become brittle over time, leading to cracks.

SOLUTIONS

● Handle with Care

Make sure the fittings are properly supported during handling and installation to avoid any impact damage.

● Protect from External Impact

Install protective barriers or provide adequate clearance around the pipeline to prevent external impact or heavy machinery from damaging the fittings.

● Avoid Rapid Temperature/Pressure Changes

Make sure the system operates within the recommended temperature and pressure limits to prevent thermal stress or pressure surges that could cause cracking.

5. DIFFICULTY TIGHTENING BOLTS OR FLANGES

POSSIBLE CAUSES

● Thread Damage or Corrosion on Bolts

If the bolts or threads are corroded or damaged, it may be difficult to tighten the bolts properly.

● Improper Torque Settings

If the bolts are not tightened to the manufacturer’s recommended torque, this can lead to either under-tightening (causing leaks) or over-tightening (causing damage).

SOLUTIONS

● Check Bolts for Damage

Regularly inspect the bolts for signs of wear, corrosion, or damage. Replace any bolts that are not in good condition.

● Use Proper Torque

Follow the manufacturer’s recommended torque settings for the bolts. Use a calibrated torque wrench to ensure accuracy.

● Lubricate Threads

Apply anti-seize lubricant to the threads of bolts to prevent rusting and make the tightening process easier.

6. DEFORMATION OF FITTINGS DUE TO OVERLOADING

POSSIBLE CAUSES

● Excessive Load on the Pipeline

Overloading the pipeline or fitting with too much weight or pressure can cause the fitting to deform or even fail.

● Improperly Sized Fittings

If the fittings are not sized correctly for the pipeline’s pressure rating or the medium being transported, they may not be able to handle the load.

SOLUTIONS

● Choose Correctly Sized Fittings

Make sure the fittings are sized correctly for the pipeline, taking into account factors like pressure rating and medium type.

● Avoid Overloading

Do not exceed the pressure or load specifications for the system. If necessary, install pressure relief valves to prevent overloading.

7. UNEVEN FLOW OR PRESSURE LOSS

POSSIBLE CAUSES

● Improperly Sized Fittings or Pipes

If the fittings or pipes are too small or too large for the application, it can cause flow restrictions or pressure loss.

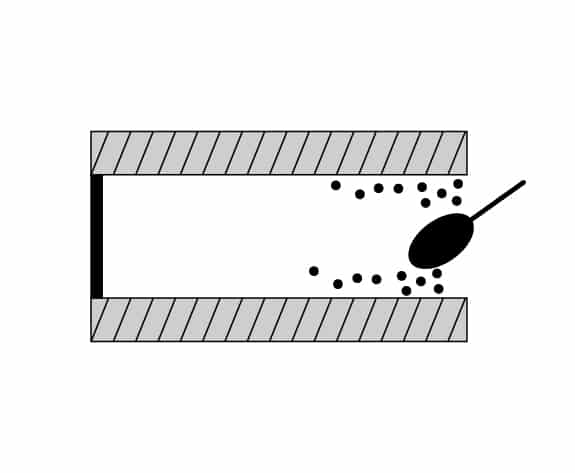

● Internal Blockages

Over time, debris or buildup inside the fittings can restrict the flow of fluid or gas, causing pressure loss.

SOLUTIONS

● Ensure Proper Sizing

Confirm that the fittings and pipes are sized correctly for the intended flow rates and pressure. This may involve working with an engineer to verify the correct specifications.

● Regular Cleaning and Maintenance

Clean the fittings and pipes regularly to prevent blockages or buildup that could restrict flow. This is especially important in systems that transport materials with high particulate content.

By understanding the common problems, possible causes, and appropriate solutions, you can take proactive steps to ensure the longevity and performance of your ductile iron pipe fittings. Regular inspections, proper installation, and choosing the right materials for specific conditions can help avoid most problems. If issues persist, it’s always a good idea to consult with judberd technician for further guidance.

WHAT IS DUCTILE FITTING AND ITS ADVANTAGE?

Ductile fitting also called ductile pipe fitting, ductile iron fitting, ductile iron pipe fitting, DI pipe fittings or DI fittings.

It is ductile iron material pipe fittings which normally be used for water supply.

Compare to grey cast iron pipe fitting,Ductile iron pipe fittings have several advantages over grey cast iron pipe fittings,

primarily due to their enhanced mechanical properties and performance characteristics. Here are the key advantages:

HIGHER STRENGTH AND DUCTILITY

DUCTILE IRON

Exhibits high tensile strength and significantly higher ductility due to its spherical graphite structure. This allows it to withstand greater internal pressures and external forces without fracturing.

GREY CAST IRON

Has lower tensile strength and limited ductility because of its flake-like graphite structure, making it more brittle and prone to cracking under stress.

IMPACT RESISTANCE

DUCTILE IRON

Better able to absorb and resist impact forces, reducing the risk of damage during handling, installation, and operation.

GREY CAST IRON

More susceptible to cracking and breaking under impact due to its brittle nature.

FLEXIBILITY

DUCTILE IRON

Offers greater flexibility, allowing it to bend slightly under stress without breaking. This property is crucial in applications where ground movement or thermal expansion may occur.

GREY CAST IRON

Rigid and less able to accommodate movement, increasing the risk of failure under dynamic conditions.

CORROSION RESISTANCE

DUCTILE IRON

Typically coated with protective layers such as epoxy, zinc, or bituminous coatings, enhancing its resistance to corrosion and extending its service life.

GREY CAST IRON

Can also be coated, but the inherent brittleness can lead to coating damage and subsequent corrosion over time.

LONGER SERVICE LIFE

DUCTILE IRON

Generally offers a longer service life due to its superior mechanical properties and resistance to environmental factors.service life due to its superior mechanic.

GREY CAST IRON

Shorter lifespan in comparison, particularly in demanding applications where mechanical stresses and environmental exposure are significant.

EASE OF INSTALLATION

DUCTILE IRON

Lighter and easier to handle compared to grey cast iron, facilitating quicker and more efficient installation.

GREY CAST IRON

Heavier and more cumbersome to work with, which can increase installation time and labor costs.

RESISTANCE TO FATIGUE

DUCTILE IRON

Better suited to withstand cyclic loads and fatigue, making it more reliable in applications with fluctuating pressures or loads.

GREY CAST IRON

More prone to fatigue failure due to its brittle nature.

DESIGN VERSATILITY

DUCTILE IRON

Can be cast into more complex shapes and thinner sections without compromising strength, providing greater design flexibility.

GREY CAST IRON

Limited by its brittle nature, which restricts the complexity of shapes and thinness of sections that can be cast.

COST-EFFECTIVENESS

DUCTILE IRON

While the initial material cost may be higher, the reduced maintenance, longer lifespan, and lower risk of failure often make ductile iron more cost-effective over the life of the installation.

GREY CAST IRON

Lower initial cost but may incur higher maintenance and replacement costs over time due to its brittleness and shorter service life.

Ductile iron pipe fittings offer superior strength, ductility, impact resistance, flexibility, and overall durability compared to grey cast iron pipe fittings. These advantages make ductile iron the preferred choice for many modern piping systems, particularly in applications requiring high performance and reliability.