Stainless steel pipe coupling is a fitting that connects two pipes together, creating a safe and leak-proof connection. typically made of SS304, SS316, or SS316L stainless steel, it is highly corrosion resistant, strong, and durable.

Judberd’s stainless steel pipe couplings come in different types—some are for connecting pipes, and some are for both connecting and repairing pipes.We have many different types stainless steel pipe couplings as below , include but not limit to Stainless steel pipe couplings that restrain, Stainless steel pipe couplings that are tough, Stainless steel pipe couplings that are fire-resistant, Stainless steel pipe couplings that repair, Stainless steel pipe couplings that have a brass grip ring and are specifically designed to connect HDPE pipe, etc.

Stainless Steel Restrained Pipe Coupling with teeth grip ring to avoid pipe to be pulled out

Stainless steel pipe coupling for pipe connection which allow for pipe expansion and contraction

Restrained pipe coupling with teeth grip ring to avoid pipe to be pulled out narrow type for limited space

Repair coupling ,single band , can repair pipeline leaks caused by aging, corrosion, sand holes, and cracks etc

Repair coupling, Double bands , can repair pipeline leaks caused by aging, corrosion, sand holes, and cracks etc

High-impact , better impact resistance and much more reliable axial pullout resistance than standard type

Fire-resistant pipe coupling, handle temperatures up to +800°C (±50°C) and provide fire resistance 90 minutes.

Combination of restraining tie rods and pipe coupling, connecting pipes and provide vibration isolation and noise reduction.

Restrained pipe coupling for HDPE Pipe, with brass grip ring to grip HDPE pipe to avoid it is to be pulled out

One end restrained another end non restrained, used to connect HDPE pipe to ductile iron, steel, PVC, GRP etc pipes

Tee pipe coupling with branch outlet, can be used to split medium from the main pipeline to branch pipeline

Why Judberd Stainless Steel Pipe Coupling?

1.Design Advantage

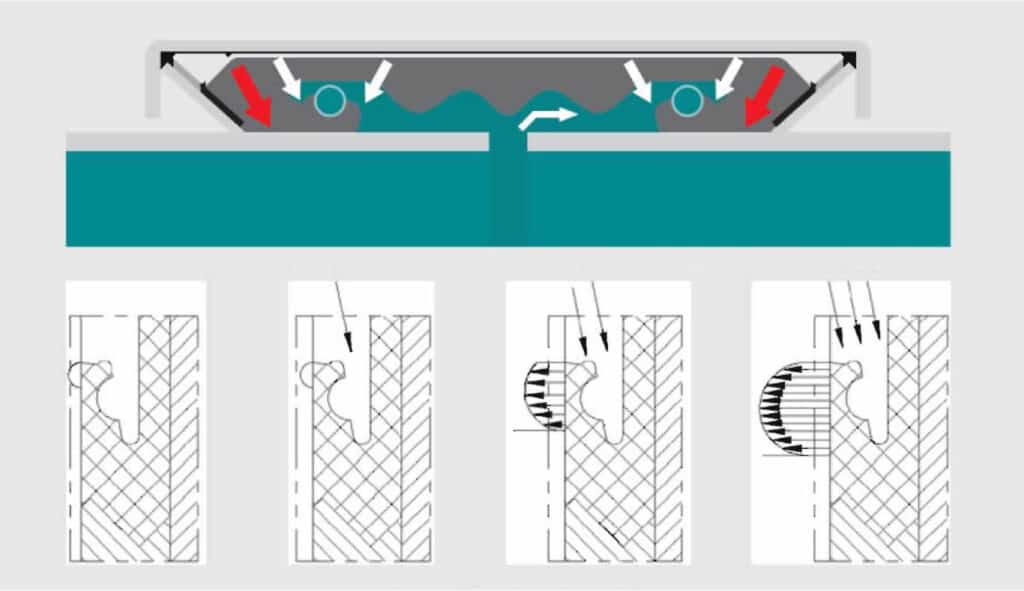

Advanced Design For Sealing Function

When the pipe contains moving liquids, gases, or dust and the internal pressure increases, the pressure on the sealing lip attached to the pipe surface also increases. The structure of the device not only prevents the medium in the pipe from leaking, but more importantly, it ensures the overall seal of the pipe.

According to Pascal’s principle in fluid mechanics, when the pipe is sealed, every point in contact with the medium experiences a normal pressure equal to the internal pressure. As a result, the base of the sealing lip is axially compressed, and the lip itself is also axially compressed. This causes the contact surface between the sealing lip and the pipe to widen, increasing the contact pressure and achieving a self-sealing effect.

Diagram of the Self-Sealing Principle of judberd stainless steel pipe coupling gasket

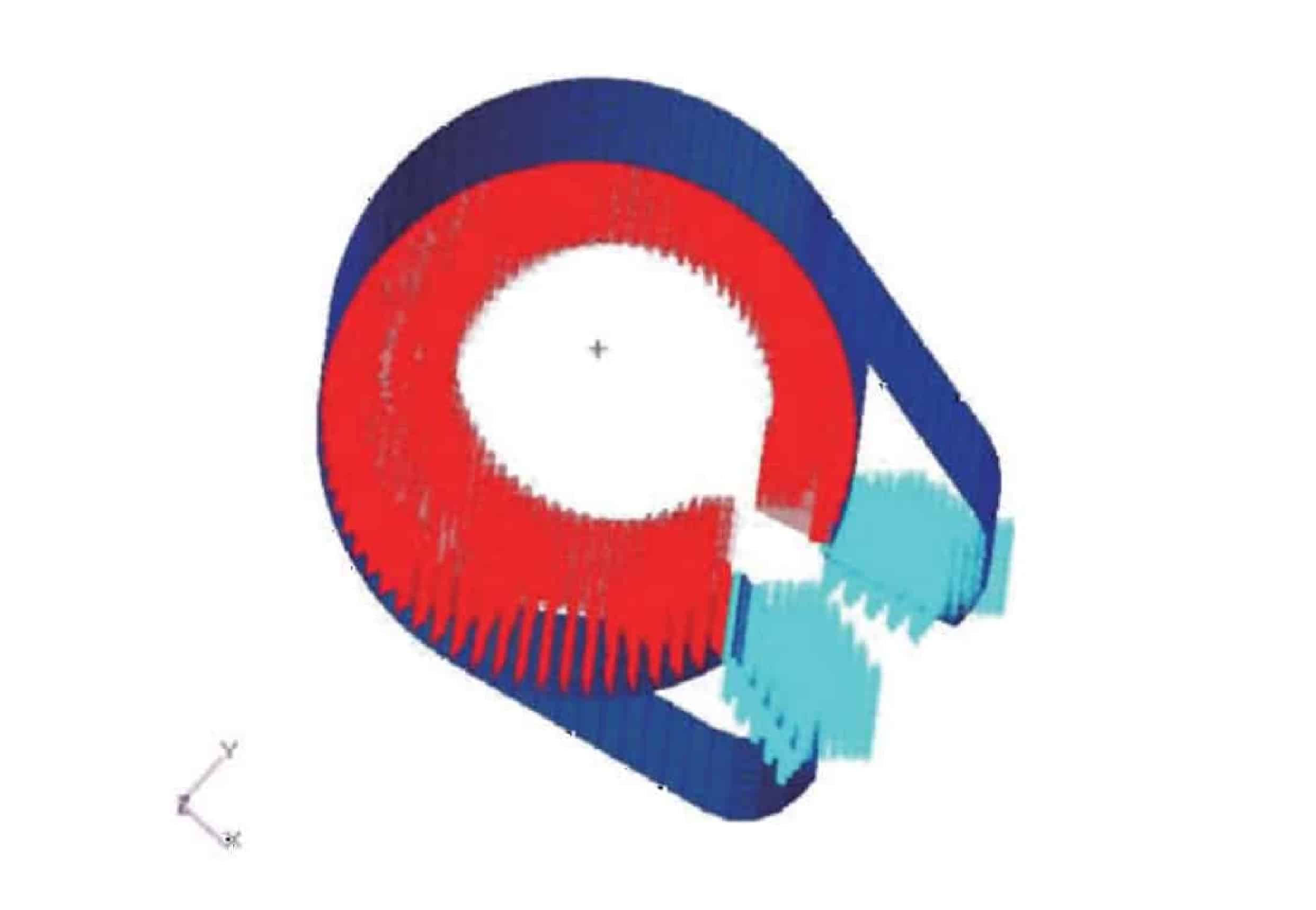

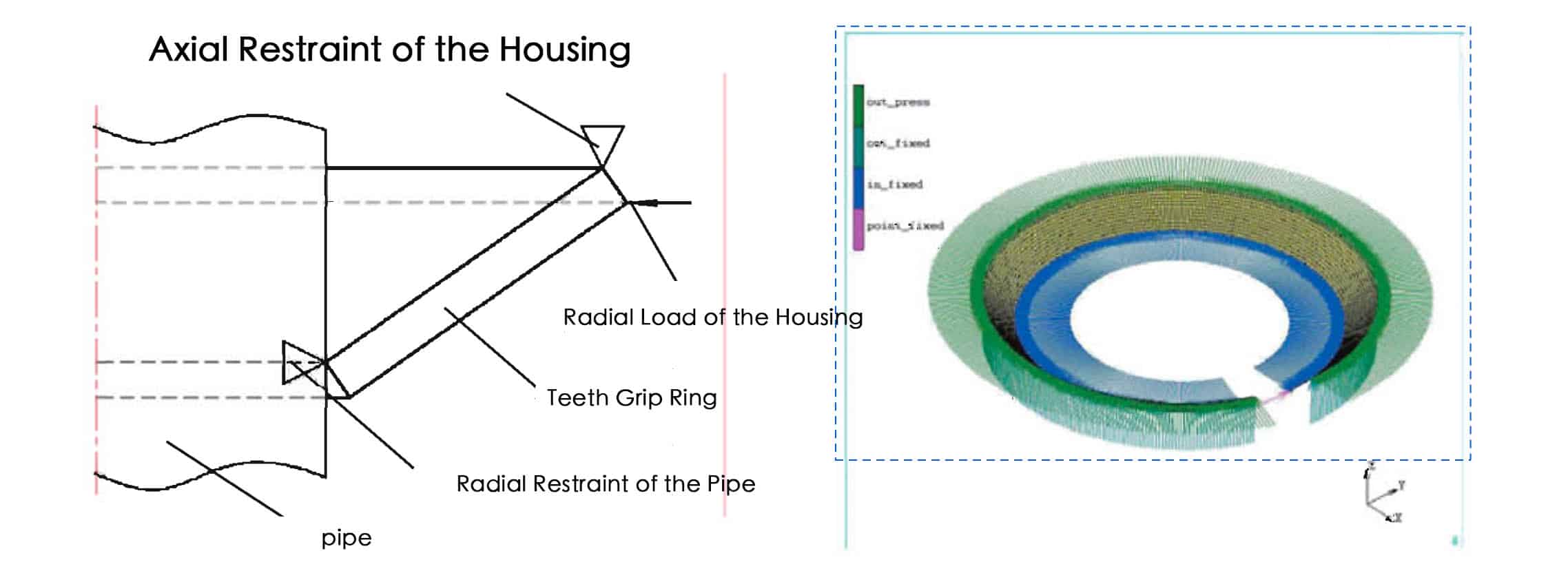

Finite Element Model of Judberd Stainless Steel Pipe Coupling Housing

Under pressure, the sealing surface fits tightly with the pipe, ensuring a seal. From actual working conditions, we know that the sealing ring mainly performs static sealing, while more severe conditions involve slight vibrations and impact oscillations. Based on the characteristics of the Y-shaped seal, it is clear that the sealing ring can handle dynamic sealing pressures above 20 MPa.

The housing is the main pressure-bearing part of the pipe coupling and directly affects the safety and reliability of its use. Therefore, a comprehensive structural mechanics analysis must be performed to determine if the strength of each stressed point meets the use requirements under the rated working pressure. Stress concentration points must be identified and modified as needed to ensure safety and reliability.

The strength of the housing is related to various factors such as the tensile strength, ductility, and thickness of the material used. The clamping force of the bolts will cause some deformation of the housing. Additionally, the lip edge of the housing will deform under pressure. These factors all affect the housing’s pressure resistance and overall safety and reliability.

Judberd optimized the housing structure based on the finite element analysis results under a 5.0 MPa pressure condition,

ensuring that the pressure-resistant housing has sufficient reserve strength.

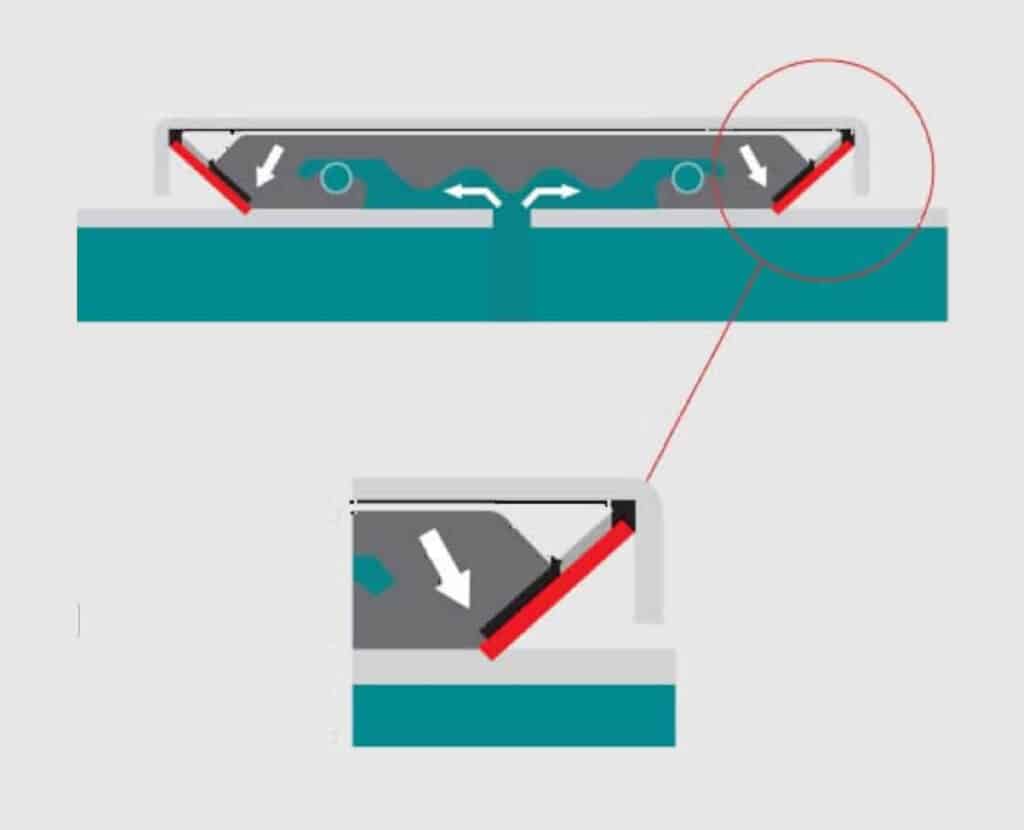

Advanced Design For Sealing Function

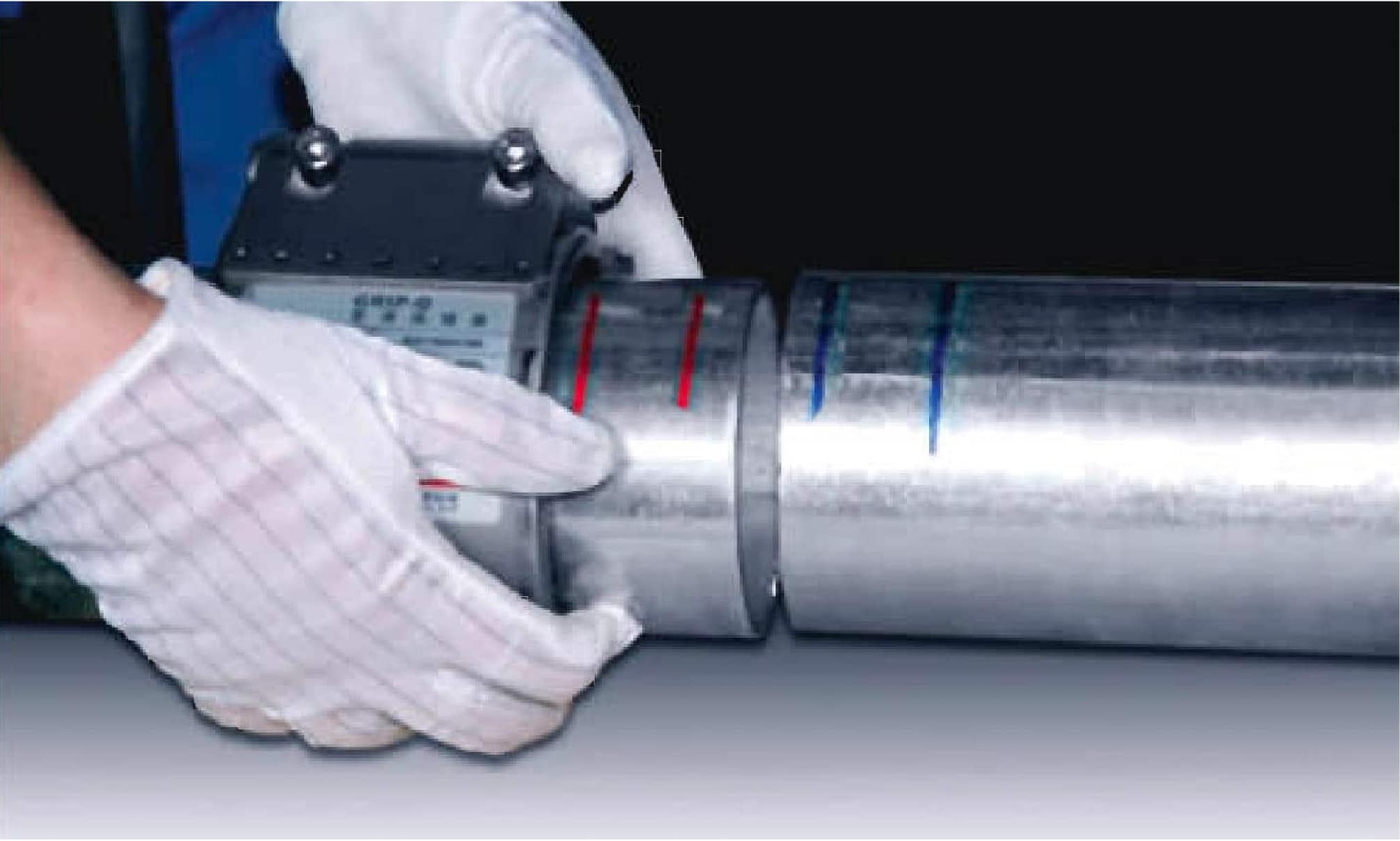

Judberd stainless steel pipe coupling adopts a cleverly designed toothed gripping structure at both ends. After installation, the teeth on the grip ring firmly bite into the outer surface of the pipe. When the internal pressure increases or external forces cause a rise in axial force, the teeth grip the pipe even tighter. The principle is illustrated in the diagram below.

Schematic Diagram of judberd Impact-Resistant Stainless

Steel Pipe Coupling’s Anti-Pull-Out Principle

Finite element analysis of the gripping strip was conducted using MARC, employing Shell elements with a thickness of 1.5mm. The gripping strip model is shown in the figure below.

Finite Element Model of the Teeth Grip Ring

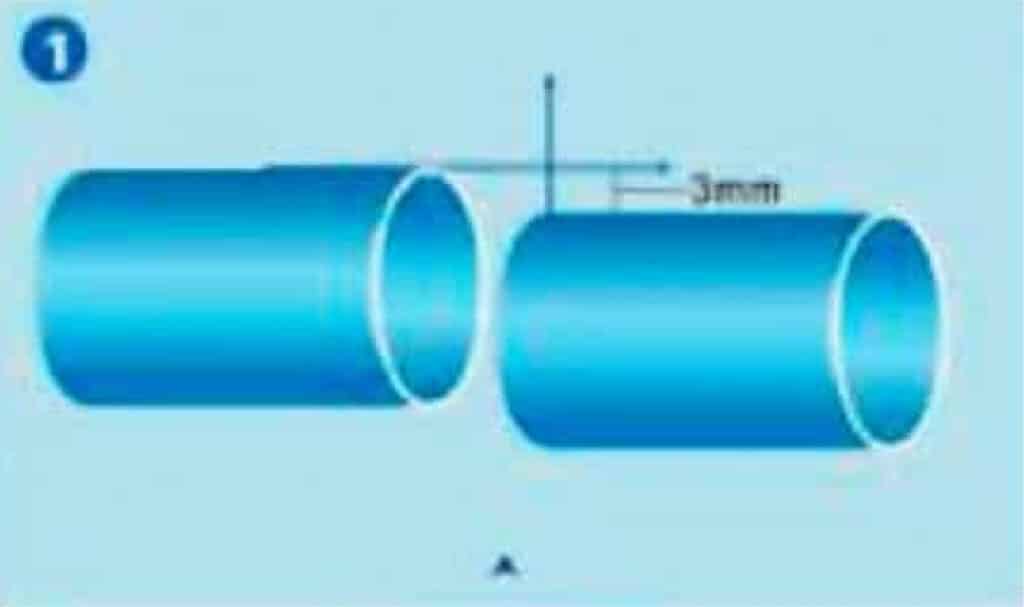

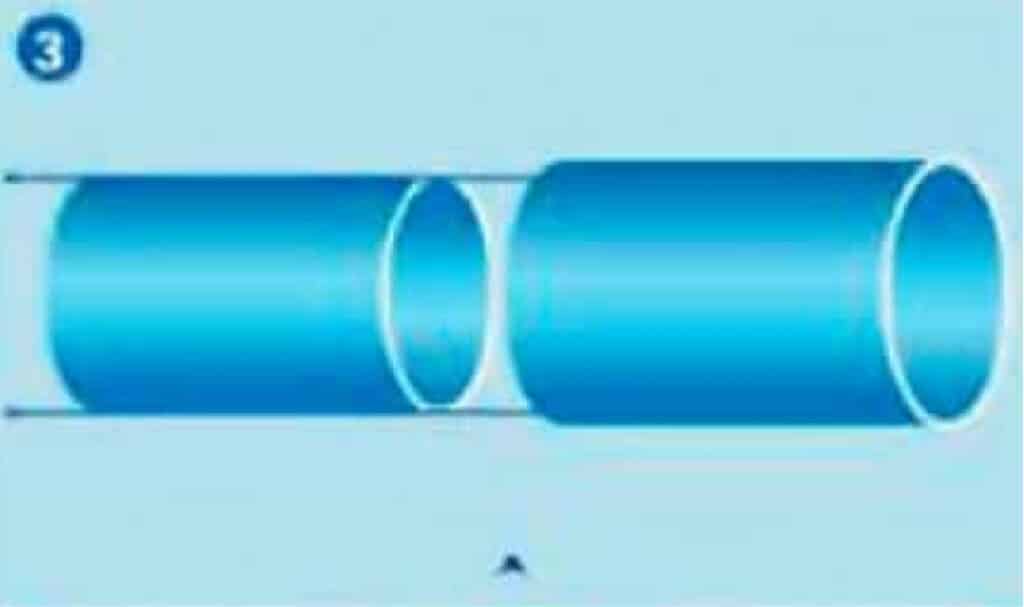

Considering the actual working conditions of the gripping strip, constraints and loads were applied as shown in the diagram. The radial restraint of the pipe and the radial load of the housing are both directed toward the axis. The radial load of the housing is applied as a displacement load, contracting inward by 3mm.

Schematic Diagram of the Constraints and Loads on the Teeth Grip Ring

The contact between the gripping strip teeth and the pipe is not merely a frictional interaction. The teeth’s cross-sectional tip has a right-angle shape. During the installation of Judberd pipe coupling and pipe, the teeth initially make line contact with the pipe. During pre-tightening, the teeth exert high pressure on the pipe surface, causing plastic deformation of the pipe’s exterior.

Using the slip theory of plane strain problems, the relationship between the pressure exerted by the gripping strip on the pipe and the critical axial force required to prevent pull-out can be determined.

2.Function Advantage

Safe and Reliable with Excellent Sealing Performance

Judberd stainless steel pipe coupling can withstand 3.2 MPa of pressure, with a maximum temperature resistance of 300°C and a maximum working pressure of 6.7 MPa, making it suitable for over 80% of the piping systems on ships. The sealing ring operates under a pressure far below its elastic limit, with a pre-tightening force of only 2 kg/cm², significantly lower than flange gaskets (which require up to 70 kg/cm²). Additionally, the equalizing pressure hole ensures that the sealing effect is proportional to the pipeline pressure, enabling long-term durability and reliable sealing.

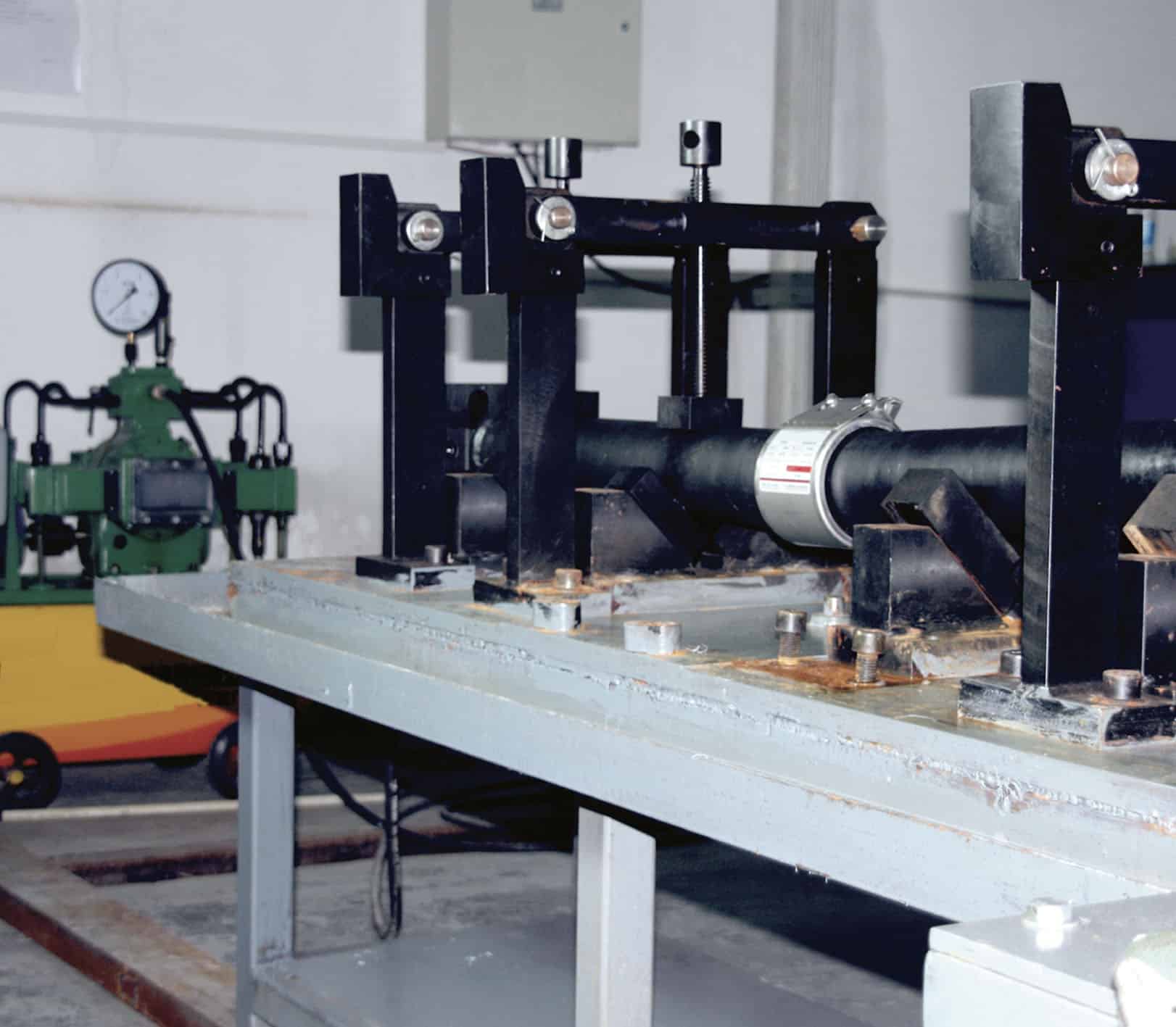

A pressure fatigue test was conducted at 0–2.5 MPa for 12,000 cycles, with no damage to the pipe body. At the connection point, fluids such as seawater primarily interact with the pipe itself and the rubber sealing ring, reducing the likelihood of galvanic corrosion between the metal housing of the pipe connector and the pipe. These measures effectively ensure reliable sealing.

Vibration Reduction, Noise Dampening, and Impact Resistance

Judberd stainless steel pipe coupling replaces rigid connections with flexible connections, helping to absorb shocks and reduce noise. Judberd stainless steel pipe coupling itself can withstand an impact load of 30g×A. Compared to flange connections, it can reduce noise intensity by 80%, which benefits the entire piping system, including pumps, valves, and other instruments, ensuring safe operation and extended service life.

Lightweight Pipe Structure

Compared to flange connections, the pipe couplings reduces weight by approximately 75%.

For example, on a single ship using an average of 3,000 pipe couplings (with sizes ranging from 48.3mm to 219.1mm), switching to these pipe couplings instead of flanges can reduce total weight by 24 tons.

3.Usage Advantage

Space-Saving in Pipe Installation

Installation and disassembly do not require full-circle flange assembly, as bolts are tightened from one side only, allowing for 50% space savings in pipe layout and construction. This is particularly significant for ships with limited space, where efficient pipe arrangement is crucial.

When pipe axes are misaligned, the connector accommodates an offset value of up to 1% (maximum 3mm), ensuring no leakage at nominal pressure. Additionally, it allows for a single-pipe angular deflection of 4° and an end gap of 5–35mm, providing generous tolerances that eliminate the need for high-precision assembly. This flexibility supports advanced shipbuilding techniques, such as modular construction and floating raft vibration isolation systems. Installation deviations or shifts due to ship movement do not negatively impact our pipe coupling’s performance.

High Compatibility and Adaptability

Judberd stainless steel pipe coupling is widely applicable to various metal and composite pipes. It is suitable for connecting pipes of the same or different materials and does not impose strict wall thickness or end face processing requirements on the connected pipes.

Quick and Convenient Installation

During on-site construction, Judberd stainless steel pipe coupling requires no assembly, and the connected pipes do not need complex adjustments or processing. A single person can complete the installation in 10 minutes using a torque wrench to tighten one or two bolts on one side, making the operation simple and efficient.

Easy Maintenance

For pipeline repairs, even when oil or water is present inside the pipe, our pipe coupling eliminates the need for welding or heating, thus avoiding fire or explosion hazards. By using double-clamp or split-type repair couplings, damaged pipes can be wrapped and repaired under pressure.

4.Cost Advantage

Facilitates Computer-Aided Design (CAD)

Since there is no need to consider flange hole alignment, CAD design is simplified, enabling easy modular design implementation and streamlining of pipeline schematics, ultimately reducing design and construction costs.

5.Strict Quality Control According to ISO9001

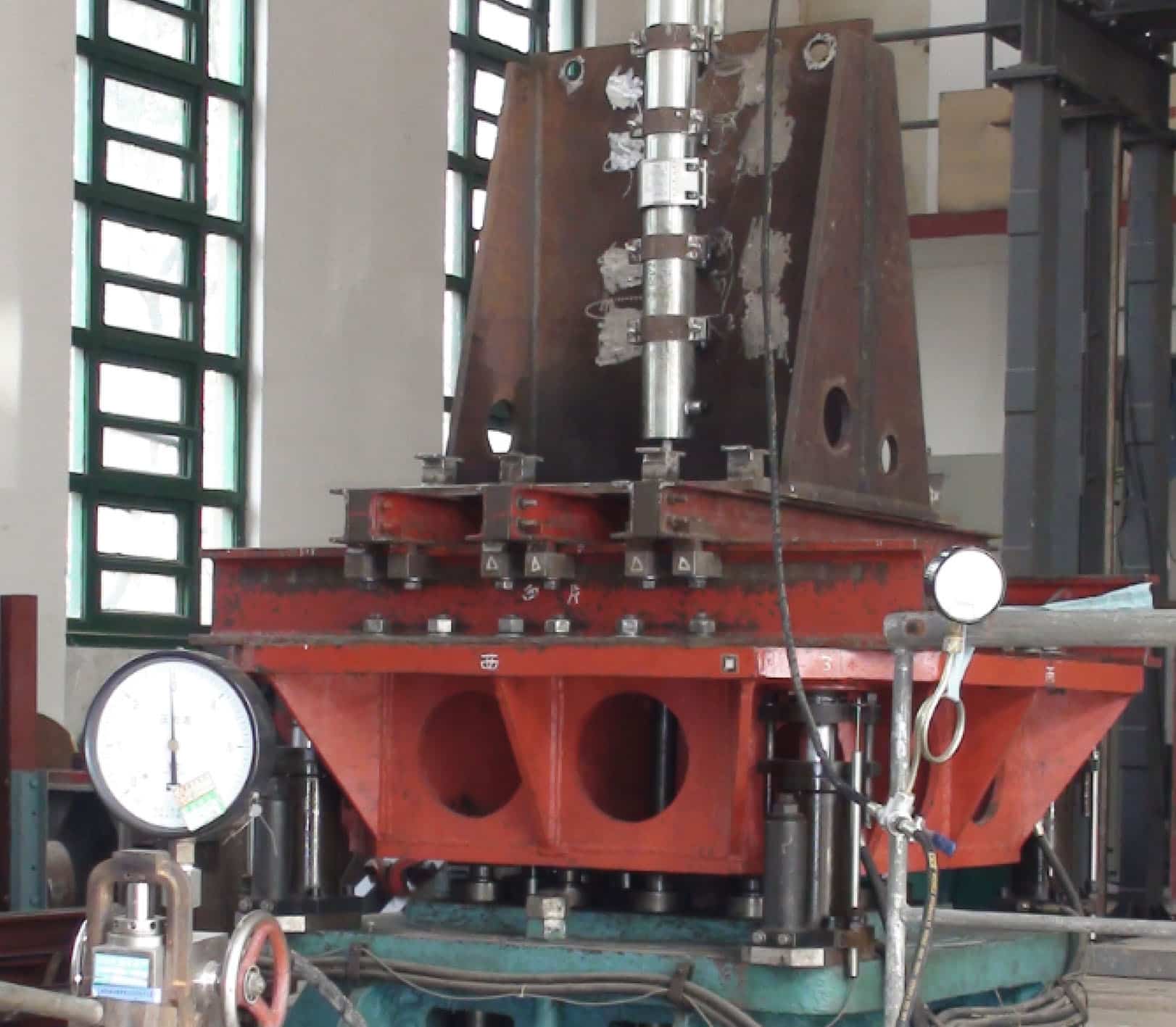

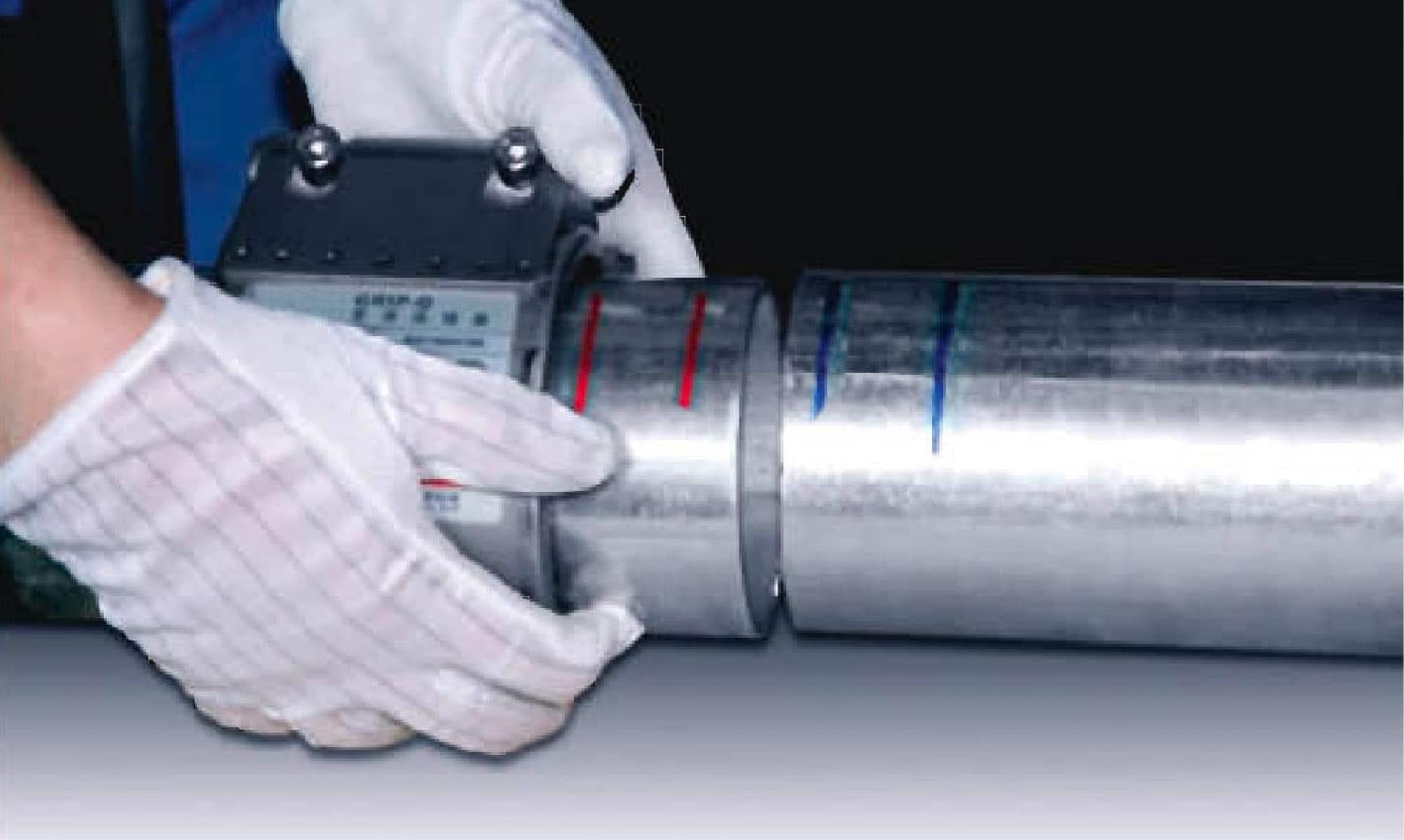

Impact resistance test

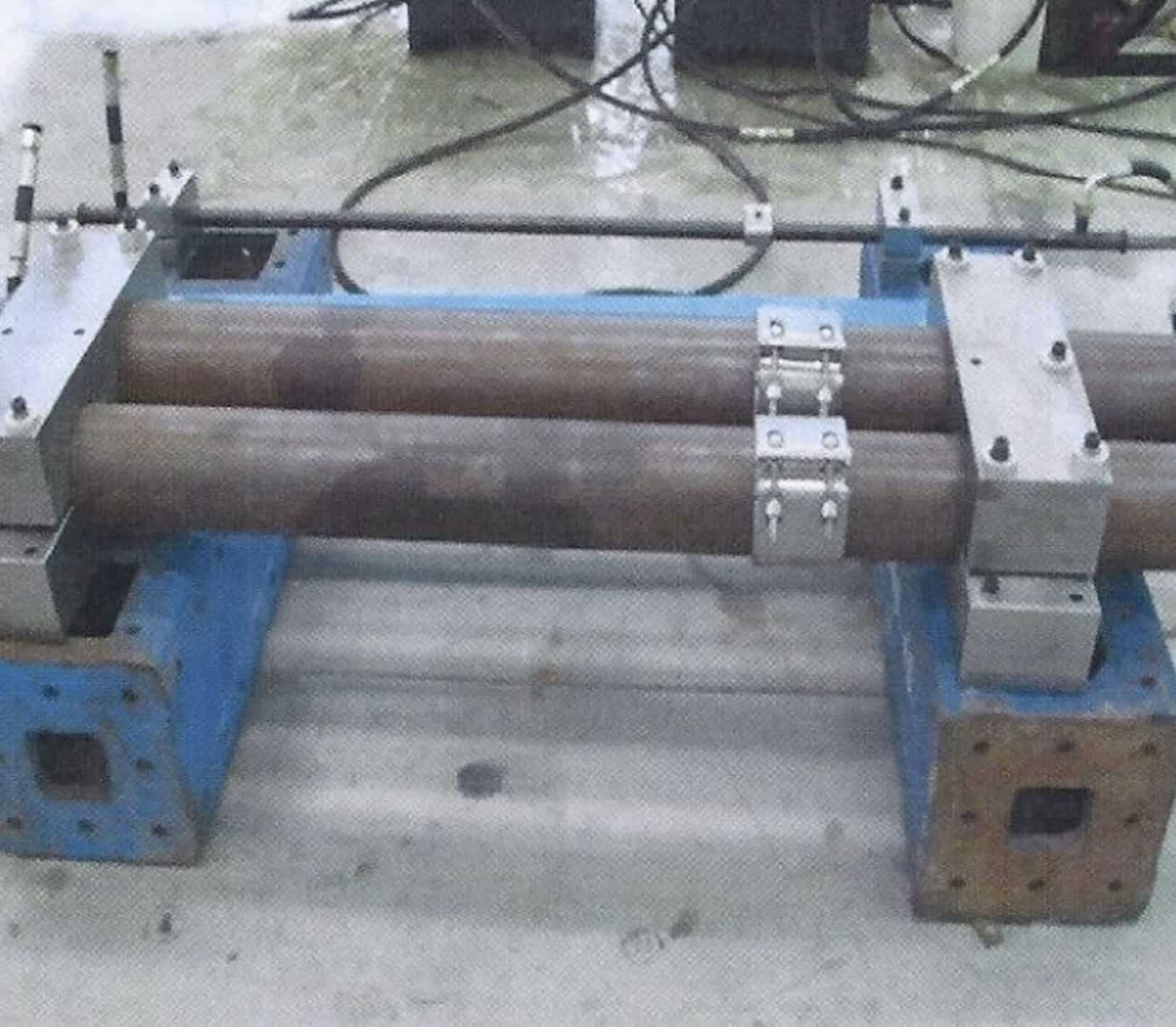

Pullout test under pressure

Vibration fatigue test

Pressure fatigue test (500,000 cycles)

Pressure test

Burst pressure test

Low temperature resistance test

High temperature resistance test

Fire resistance test

Vacuum test

Use

Application system

Stainless steel pipe couplings are used in a wide range of applications, including:

MATERIAL COMPATIBILITY

_

Drinking water, tap water, and industrial water pipes (SS316 for food-grade applications)

Seawater and Desalination Systems

_

Marine environments and offshore projects (SS316/SS316L for saltwater corrosion resistance)

Oil and Gas

_

Crude oil, natural gas, and liquefied petroleum gas (high pressure and corrosion resistance)

Chemicals

_

Acids, alkalis, and chemical solvents (SS316L for highly corrosive environments)

Food and Pharmaceutical

_

Food-grade liquids and medical fluids (meets hygiene standards)

Heating and Cooling

_

HVAC, cooling water, and hot water circulation (high temperature and oxidation resistance)

Fire Protection

_

Firefighting water and foam extinguishing systems (durable and corrosion resistant)

Wastewater

_

Sewage and wastewater transport (corrosion and pollution resistant)

Industrial Gases

_

Oxygen, nitrogen, and compressed air transport (airtight and high pressure)

Function

CONNECT PIPES

_

Securely join two pipes to ensure stable fluid or gas transport even for two pipes that have Axial movement, angular deflection, different outside diameters.

SEAL

_

Prevent leaks and maintain the integrity of the pipe system,

HANDLE HIGH PRESSURE

_

Work in high-pressure pipes to maintain safety,

RESIST CORROSION

_

Work in harsh environments like seawater and chemical applications

ABSORB VIBRATION AND SHOCK

_

Flexible couplings help reduce stress from vibrations

INSTALL AND MAINTAIN EASILY

_

Available in threaded, welded, and quick connect for different needs

STAINLESS STEEL PIPE COUPLING ARE CORROSION RESISTANT

_

More resistant to acids, alkalis, moisture, and oxidation than carbon steel and ductile iron

CLEAN AND SAFE

_

Suitable for food and pharmaceutical applications without contaminating what you’re moving,

STRONG

_

Work in high-pressure and high-temperature applications

LAST

_

Work in high-pressure and high-temperature applications

AXIAL MOVEMENT

ANGULAR DEFLECTION

DIFFERENT OUTSIDE DIAMETERS

Installation

Prepare

Pick the Right Coupling – Choose based on pressure, temperature, and what you’re doing.

Use the Right Tools – Torque wrench

Follow Judberd’s Torque Specs – Don’t over-tighten and damage things.

Installation

1, Check Pipe Alignment – Make sure the pipes are lined up before you start.

2, Remove any sharp edges from the pipe ends – This will prevent damage to the rubber components of the stainless steel pipe coupling.

3, Mark the maximum and minimum insertion depth on each pipe – This will ensure proper positioning during the installation process.

4, Slide the stainless steel pipe coupling onto the pipe – Adjust the gap between the two pipe ends within the allowable range (please refer to the Judberd Stainless Steel Pipe Coupling User Manual for specific guidelines).

5, Adjust the pipe insertion depth – The first mark (closer to the pipe end) should be inside the stainless steel pipe coupling, while the second mark (farther from the pipe end) should remain visible outside the coupling.

6, Tighten the bolts gradually – Follow the specified torque values, tightening alternately in multiple steps from low to high. (The recommended torque values are usually indicated on the product label.)

7, Leak Test – Slowly bring the pressure back up and check for leaks.

Stainless steel pipe coupling VS Ductile iron pipe coupling

When you’re choosing a pipe coupling, you need to make sure you’re picking the right material based on where you’re working, the pressure, what you’re moving, and how much corrosion resistance you need. Here’s a detailed comparison between stainless steel pipe couplings and ductile iron pipe couplings to help you figure out which one is going to work best for you.

Stainless steel pipe coupling

Ductile iron pipe coupling

What They’re Made Of and How They Resist Corrosion

Stainless Steel Pipe Coupling

_

● What It’s Made Of:

Made from stainless steel like SS304, SS316, or SS316L, which is really good at resisting corrosion.

● How It Resists Corrosion:

It’s really good at resisting rust, chemicals, and seawater, which makes it great for places like the coast or in the chemical industry.

● How Long It Lasts:

It’s going to last a lot longer because it’s really good at resisting rust and wear.

Ductile Iron Pipe Coupling

_

● What It’s Made Of:

Made from ductile cast iron (nodular cast iron) and usually coated with epoxy or zinc to keep it from rusting.

● How It Resists Corrosion:

It’s pretty good at resisting water and underground stuff, but it’s not as good with chemicals and saltwater as stainless steel.

● How Long It Lasts:

It’s not going to last as long as stainless steel in really bad places, but it’s still going to last a long time in your average pipe.

● If you’re in a really bad place (like the ocean, chemicals, or really bad weather) → Go with stainless steel pipe coupling.

● If you’re in regular water, gas, and oil pipes with not a lot of chemicals → Ductile iron pipe coupling is a good way to save some money.

How Strong They Are and What They Do

Stainless Steel Pipe Coupling

_

● How Strong It Is:

It’s stronger than ductile iron when it comes to not breaking and bending.

● What It Does:

You can get it in a rigid or flexible design, which means it can move a little bit or not line up perfectly.

Ductile Iron Pipe Coupling

_

● How Strong It Is:

It’s more ductile than regular cast iron, which means it can take a hit and not break.

● What It Does:

It can handle a lot of weight, which is good for big pipes or putting it underground where there’s a lot of weight.

● If you’re doing something really hot or really high pressure, you want stainless steel pipe coupling.

● If you’re doing something regular with pressure and temperature, you want ductile iron pipe coupling.

How Heavy They Are and How Easy They Are to Put In

Stainless Steel Pipe Coupling

_

● How Heavy It Is:

It’s light, which means it’s easier to move and put in, which saves you money on labor.

● What You Need to Do:

You don’t have to do anything special to keep it from rusting because it’s stainless steel.

Ductile Iron Pipe Coupling

_

● How Heavy It Is:

It’s heavy, which means it’s harder to move and put in, especially if you’re using big pipes.

● What You Need to Do:

You have to put epoxy or zinc on it to keep it from rusting, and that can wear off over time.

● If you want something light and easy to put in, you want stainless steel pipe coupling.

● If you’re doing something big, underground, or for the city, you want ductile iron pipe coupling.

How They Handle Heat and Pressure

Stainless Steel Pipe Coupling

_

● How They Handle Heat:

They can handle really hot and really cold temperatures, which is good for hot water, steam, and really cold stuff.

● How They Handle Pressure:

They can handle a lot of pressure, which is good for when you’re doing something industrial.

Ductile Iron Pipe Coupling

_

● How They Handle Heat:

They can handle regular temperature changes, but they’re not good for really hot or really cold stuff.

● How They Handle Pressure:

They can handle medium to high pressure, which is good for most city water and gas pipes, but not for really high pressure.

● If you’re doing something really hot or really high pressure, you want stainless steel pipe coupling.

● If you’re doing something regular with pressure and temperature, you want ductile iron pipe coupling.

How Much They Cost

Stainless Steel Pipe Coupling

_

● How Much It Costs at First:

It’s more expensive because it’s better.

● How Much It Costs to Keep It Up:

You don’t have to replace it or recoat it all the time, which means you save money in the long run.

Ductile Iron Pipe Coupling

_

● How Much It Costs at First:

It’s cheaper than stainless steel.

● How Much It Costs to Keep It Up:

You have to put coatings on it and check it all the time for rust.

● If you’re worried about money, you want ductile iron pipe coupling.

● If you’re worried about saving money and having something that lasts a long time, you want stainless steel pipe coupling.

Where You Should Use Them

| Application | Stainless Steel Pipe Coupling | Ductile Iron Pipe Coupling |

|---|---|---|

| Drinking Water Pipelines | ✅ Excellent (hygienic and corrosion-resistant) | ✅ Good (safe but needs coating) |

| Seawater and Coastal Pipelines | ✅ Best Choice (high corrosion resistance) | ❌ Not Recommended (prone to corrosion) |

| Oil and Gas Pipelines | ✅ Suitable for corrosive environments | ✅ Commonly used for general conditions |

| Chemical and Industrial Applications | ✅ Best Choice (resistant to chemicals) | ❌ Not Recommended (corrosion risk) |

| Underground Water Pipelines | ✅ Good (lightweight and corrosion-resistant) | ✅ Best Choice (impact-resistant) |

| High-Pressure Steam and Heat Systems | ✅ Best Choice (withstands high temperatures) | ❌ Not Suitable (temperature limitations) |

| Municipal and Large-Diameter Pipelines | ✅ Good for flexibility and corrosion resistance | ✅ Best Choice (cost-effective for large projects) |

What You Should Get

Get Stainless Steel Pipe Coupling If

_

● You’re in a place that’s really bad (like the ocean, chemicals, or really bad weather).

● You need something strong, long-lasting, and that can handle really hot and really cold temperatures.

●You want something you don’t have to keep up all the time and that will save you money in the long run.

● You’re using a small pipe and you need it to move a little bit.

Get Ductile Iron Pipe Coupling If

_

● You’re putting a pipe underground or you’re using it for city water.

● You need something that’s cheap and that will work for regular water, oil, and gas pipes.

● You’re using a big pipe and you need it to take a hit.

● You’re not in a place that’s really bad.

● Both of them have good things about them. Stainless steel pipe couplings are better for places that are really bad, need high pressure, and need to handle really hot and really cold temperatures. Ductile iron pipe couplings are cheaper for regular water and underground pipes.