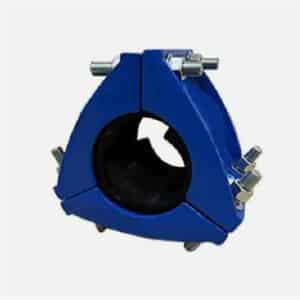

Express Joint Fitting Manufacturer

The Express Joint consists of the body, follower, gasket, and bolts. By tightening the bolts, the follower and the body compress and deform the gasket to form a seal. Unlike a push-on joint, the express joint is a mechanical joint, which does not rely on the precision of the pipe material to achieve sealing. Unlike a flanged joint, which is a rigid connection with poor deflection capability, the express joint allows angular deflection, is easy to install, and does not require a large amount of jointing force.

Judberd is competitive manufacturer for express fittings include but not limit to express bend, express tee , express flange socket etc, photos are as below

Applications & Reasons

1. Restricted Installation Conditions

_

● Situation: Tunnels, basements, narrow trenches, or congested areas where space is limited and it is difficult to apply high insertion force.

● Why Express Joint?

It requires no jointing force; sealing is achieved by mechanical compression with bolts, making installation quick and easy in confined spaces.

2. Pipes with Low Dimensional Accuracy

_

● Situation: Locally produced pipes or pipes with larger tolerances where the outer diameter accuracy cannot be guaranteed.

● Why Express Joint?

Unlike push-on joints, which rely on precise pipe dimensions, the Express Joint provides reliable sealing through mechanical compression of the gasket, independent of pipe accuracy.

3. Ground Settlement or Soil Movement

_

● Situation: Projects in soft soil, areas with potential ground settlement, or pipelines exposed to soil scouring or vibration.

● Why Express Joint?

It allows angular deflection (1°–5° depending on DN) and limited axial gap, enabling the pipeline to absorb small displacements and reduce the risk of leakage.

4. Quick Installation and Easy Maintenance

_

● Situation: Emergency repairs, frequent maintenance pipelines, or projects requiring faster construction schedules.

● Why Express Joint?

Assembly and dismantling are simple with standard tools; no large jointing force or precise flange alignment is needed, saving time and labor.

5. Comparison with Other Joints

_

● Versus Push-on Joint:

Express Joint is better when pipe accuracy is low or when it is difficult to apply insertion force.

● Versus Flange Joint:

Express Joint is more flexible, allowing angular deflection and gap absorption, while flange joints are rigid.

● Versus Other Flexible Joints (e.g., Flexible Coupling):

Express Joint has simpler structure, lower cost, and still provides flexibility for movement and settlement.

Conclusion

_

Customers should choose Express Joint when:

- Installation space is limited or conditions are difficult;

- Pipe dimensional accuracy is not reliable;

- The project requires angular deflection or settlement absorption;

- Fast installation and maintenance are needed.

Express Joint offers a balance of flexibility, reliability, and easy installation, making it the best choice in complex field conditions where push-on joints or flange joints are less suitable.

Installation Guide

1. Preparation

_

● Clean the pipe spigot and the socket chamber thoroughly.

● Remove any rust, dirt, grease, or foreign materials.

● Check the gasket, gland, and bolts for damage. Replace if necessary.

2. Position the Gasket

_

● Place the elastomer gasket into the socket seat.

● Ensure it is properly aligned in its groove without twisting.

3. Insert the Pipe Spigot

_

● Carefully align the pipe spigot with the socket.

● Insert it into the socket until it reaches the correct depth.

● A cylindrical bearing surface inside the socket helps alignment.

4. Position the Gland

_

● Place the ductile iron gland inside the socket against the gasket.

● Make sure the gland sits evenly around the spigot.

5. Insert and Tighten the Bolts

_

● Insert bolts into the external socket rim, ensuring bolt heads anchor correctly.

● Hand-tighten all bolts first to ensure even contact.

● Then tighten bolts gradually and evenly in a cross/star sequence to compress the gasket.

● The gasket seals by axial compression between the gland and the socket wall.

6. Final Check

_

● Confirm all bolts are tightened to the recommended torque values.

● Ensure the joint is evenly compressed.

● Check angular deflection or gap (if designed for it) is within allowable limits.

● Pressure-test the pipeline according to EN 545 / ISO 2531 requirements.

Key Notes

_

● No insertion force is required during assembly, unlike push-on joints.

● Express Joints allow angular deflection and slight axial gap — but these must remain within specified values.

● Always follow the torque recommendations provided by the manufacturer to ensure proper sealing performance.

Express Joint VS Push-on Joint VS Flange Joint

| Criteria | Express Joint | Push-on Joint | Flange Joint |

|---|---|---|---|

| Sealing Principle | Mechanical sealing: gasket compressed by gland & bolts | Push-in sealing: pipe spigot inserted into gasket seat | Flange face & gasket compressed by bolts |

| Dependence on Pipe Accuracy | Low – independent of pipe dimensional precision | High – requires precise pipe outer diameter | Medium – requires proper flange alignment and surface finish |

| Required Jointing Force | Very low – no insertion force needed | High – needs significant pushing force | High – requires bolt torque and accurate flange alignment |

| Installation Efficiency | High – quick assembly, easy dismantling | Medium – slower due to high insertion force | Low – time-consuming, requires precise flange matching |

| Angular Deflection | Yes – allows 1°–5° depending on DN, reduces need for bends | Limited – small flexibility | None – rigid connection |

| Axial Gap Absorption | Yes – absorbs small expansion or settlement | Very limited | None – rigid joint |

| Best Application Scenarios | Restricted sites (tunnels, basements, congested areas); soft soil; quick installation/repair | Long straight pipelines with stable ground and precise pipe dimensions | Rigid connection with valves, pumps, and equipment (no movement allowed) |

| Key Advantages | Flexible, reliable sealing, easy to install in difficult conditions | Cost-effective for standard projects with accurate pipes | Strong rigid connection, standardized for equipment interfaces |