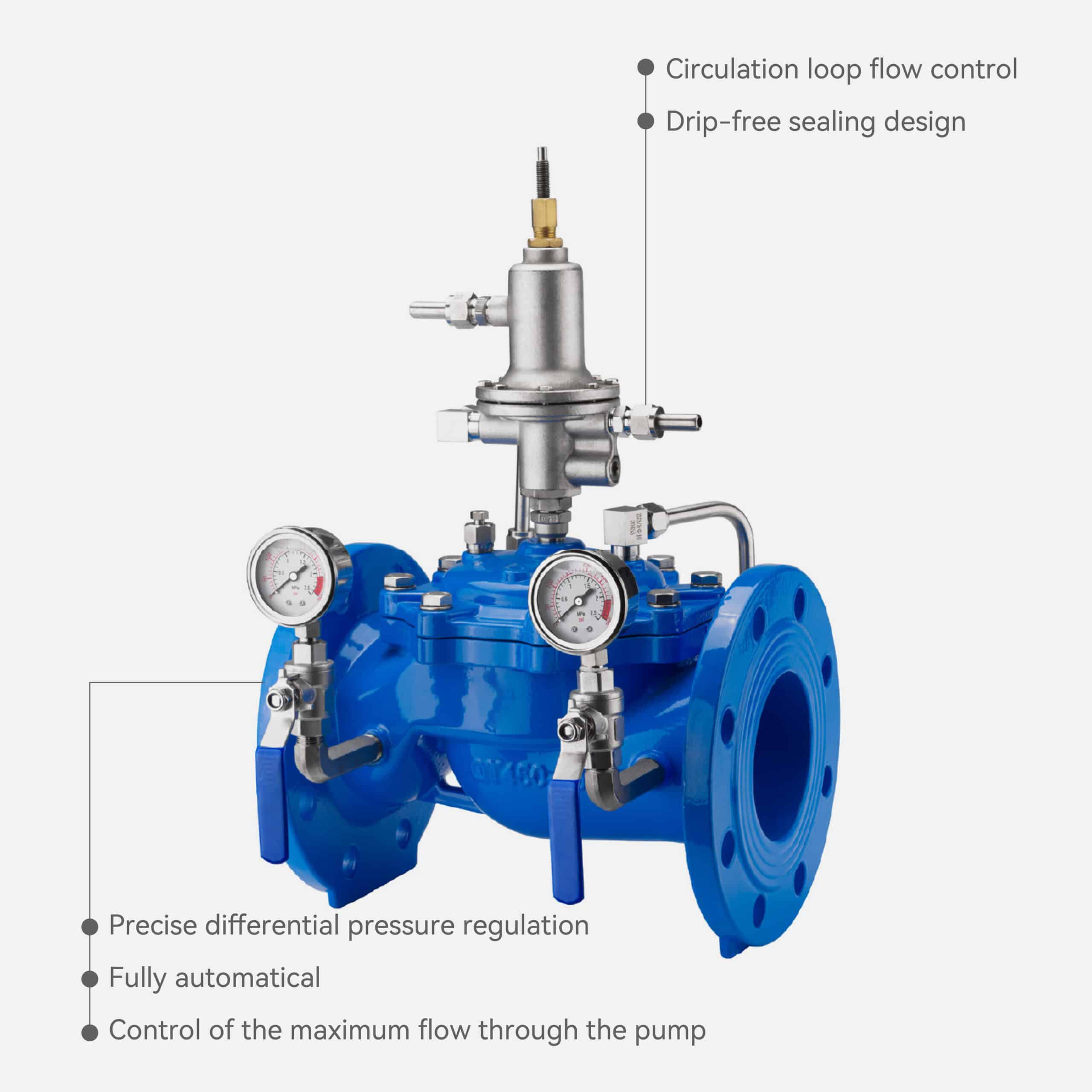

Adjustable Pressure Reducing Valve

The adjustable pressure reducing valve is used in domestic water supply, fire-fighting water supply, and other industrial water systems.

By adjusting the pilot valve, the outlet pressure of the main valve can be regulated.

The outlet pressure remains constant regardless of fluctuations in inlet pressure or flow rate, ensuring safe and reliable operation while maintaining the outlet pressure at the preset value.

The set value can also be adjusted as needed to achieve pressure reduction.

FEATURE

● Size DN50-DN800

● Working Pressure PN10/PN16/PN25

● Maximum Inlet Pressure Same as Working Pressure

● Minimum Outlet Pressure 0.05 Mpa

● Minimum Pressure Difference 0.1 Mpa

● Flow Characteristic Deviation ≤10%

● Pressure Characteristic Deviation

PN10≤ 4% set outlet pressure ;PN16&PN25≤ 5%set outlet pressure

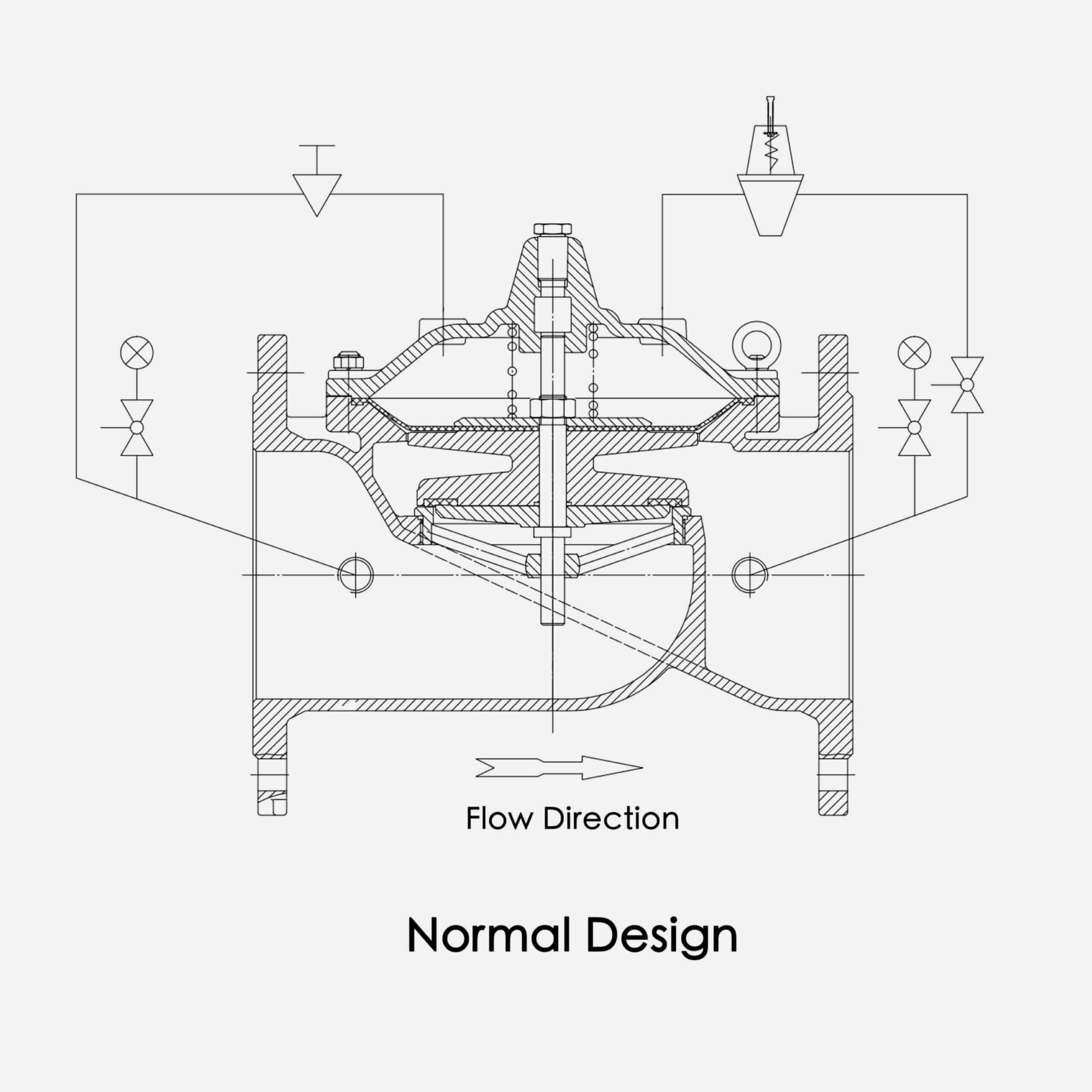

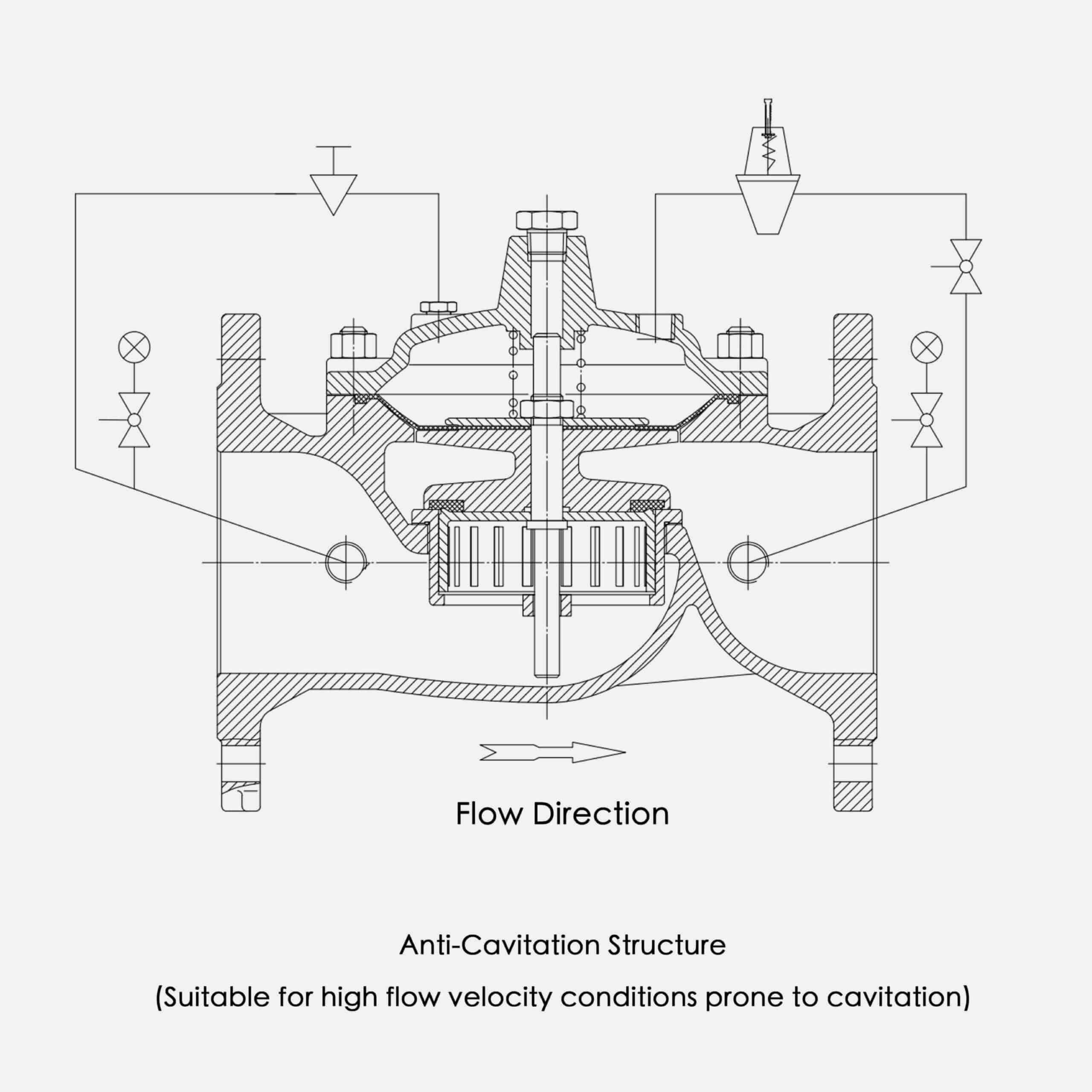

Types & Application

Adjustable Pressure Reducing Valve normal design drawing

Anti-Cavitation Design pressure reducing valve

Causes and Prevention Methods of Cavitation

1. Main Causes of Cavitation

Cavitation occurs when the local pressure inside the valve drops below the vapor pressure of the fluid, causing part of the liquid to vaporize and form bubbles.

As these vapor bubbles move into higher-pressure regions, they collapse violently, creating noise, vibration, and erosion damage on metal surfaces such as the valve seat or body.

Below are the most common causes of cavitation in pressure reducing valves:

| Cause | Description | Typical Application |

|---|---|---|

| 1. Excessive Pressure Differential (ΔP too high) | The inlet pressure is much higher than the outlet pressure, leading to a sharp pressure drop inside the valve. | High-pressure transmission → low-pressure distribution |

| 2. Excessive Flow Velocity | When the flow rate or valve opening is too large, the velocity near the seat or orifice increases sharply, causing a pressure drop below vapor pressure. | Operation at small openings or high flow conditions |

| 3. Outlet Pressure Set Too Low | If the set outlet pressure is too low, part of the valve interior may fall below the vapor pressure. | Users pursuing an excessive pressure reduction ratio |

| 4. High Fluid Temperature | Higher temperature reduces the vapor pressure of the fluid, making cavitation easier to occur. | Hot water or industrial circulation systems |

| 5. Poor Piping Design | Elbows, reducers, or short straight runs before/after the valve cause turbulence and local pressure fluctuations. | Valve installed near elbows or pump outlets |

2. Prevention Methods for Each Cavitation Cause

| Cause | Description | Typical Application |

|---|---|---|

| 1. Excessive Pressure Differential (ΔP too high) | The inlet pressure is much higher than the outlet pressure, leading to a sharp pressure drop inside the valve. | High-pressure transmission → low-pressure distribution |

| 2. Excessive Flow Velocity | When the flow rate or valve opening is too large, the velocity near the seat or orifice increases sharply, causing a pressure drop below vapor pressure. | Operation at small openings or high flow conditions |

| 3. Outlet Pressure Set Too Low | If the set outlet pressure is too low, part of the valve interior may fall below the vapor pressure. | Users pursuing an excessive pressure reduction ratio |

| 4. High Fluid Temperature | Higher temperature reduces the vapor pressure of the fluid, making cavitation easier to occur. | Hot water or industrial circulation systems |

| 5. Poor Piping Design | Elbows, reducers, or short straight runs before/after the valve cause turbulence and local pressure fluctuations. | Valve installed near elbows or pump outlets |

3. Additional Recommendations

Use valves with multi-hole or multi-stage anti-cavitation structures

Regularly inspect valve seat and plug for erosion

Install pressure gauges or transmitters to monitor differential pressure

For high-pressure systems, adopt staged pressure reduction or bypass relief lines

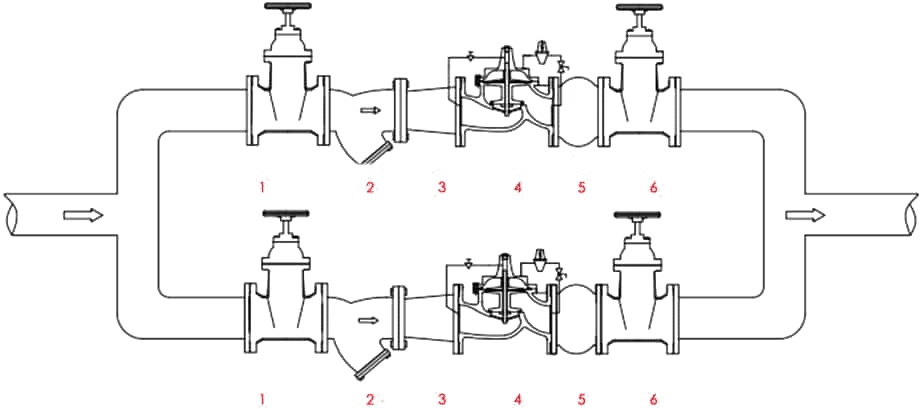

Installation

I. Overall Installation Layout

For a reliable and uninterrupted water supply, the main pipeline should have two parallel branches, each with a complete set of valves and accessories.

This way, one valve can work while the other is on standby or both can work together during high flow conditions.

Each branch should be installed in this order (in the direction of water flow):

Shut-off Valve → Strainer → Reducer (big end connected to PRV) → Pressure Reducing Valve → Rubber Flexible Joint → Shut-off Valve

Both branches connect to the main inlet and outlet headers, with optional bypass lines and pressure gauges for monitoring and commissioning.

II. Component Positions and Functions

| Component | Installation Position | Function / Reason |

|---|---|---|

| Shut-off Valve | Installed before and after the branch line | Allows isolation of each branch during maintenance or replacement without affecting the other line. |

| Strainer (Filter) | Installed upstream of the PRV | Filters out debris, rust, sand, and welding residue to protect internal PRV components and ensure stable pressure control. |

| Reducer (Expansion Pipe) | Installed between the strainer and the PRV | When the upstream pipe diameter is smaller than the PRV size, a reducer ensures a smooth flow transition from smaller to larger diameter, reduces flow velocity, improves flow stability, and minimizes turbulence and noise. The large end must connect to the PRV inlet. |

| Adjustable Pressure Reducing Valve (PRV) | Installed after the reducer | Regulates and stabilizes downstream pressure to the preset outlet pressure, protecting downstream pipelines and equipment. The arrow on the valve body must match the flow direction. |

| Rubber Flexible Joint | Installed at the PRV outlet | Absorbs vibration and noise, mitigates water hammer, and compensates for pipe movement caused by temperature changes or installation misalignment. |

| Pressure Gauges (Recommended) | Installed at both PRV inlet and outlet | For monitoring inlet and outlet pressures, adjusting setpoints, and observing valve performance. |

III. Installation Steps

Pipeline Cleaning

_

Before installing, flush and clean the entire system thoroughly to remove rust, sand, and welding debris.

Confirm Flow Direction

_

Make sure the installation direction matches the arrow on the PRV body.

If you install the valve backward, it won’t work or will be damaged.

Sequential Component Installation

_

Install in this order:

Shut-off Valve → Strainer → Reducer (big end toward PRV) → PRV → Rubber Flexible Joint → Shut-off Valve

Make sure the flanges are aligned correctly and the sealing gaskets are in the right place.

Installation Orientation and Space

_

The PRV should be installed horizontally on a level section of the pipeline;

If you install it in a pit or chamber, make sure there is enough space around the valve to lift and maintain it;

Make sure you have enough room to turn the ball valve handles and needle valve handwheels.

Parallel Installation (Recommended)

_

Install two identical PRV assemblies in a parallel configuration;

This way, one valve can work, the other can stand by, or both can work together during peak demand;

Each branch should have shut-off valves at the inlet and outlet for isolation and easy maintenance.

System Commissioning

_

Before you supply water, make sure all the shut-off valves and ball valves on the PRV are fully open.

Open the upstream valve slowly to avoid water hammer.

Watch the pressure gauges and adjust the outlet pressure to the setpoint you want.

IV. Installation Precautions

01

Don’t install the PRV upside down or vertically unless it’s designed specifically for vertical mounting.

02

Always install a strainer upstream of the PRV to prevent clogging and malfunction.

03

If you install it in a damp or underground area, take measures to protect it from moisture.

04

When you start the system or restart it after a shutdown, open the upstream valves slowly to avoid water hammer.

05

Clean the strainer regularly to maintain the flow stability and control accuracy.

V. Summary

Installing a reducer before the pressure reducing valve ensures a smooth flow transition and reduces turbulence, vibration, and noise, which improves the accuracy and service life of the valve.

A dual parallel configuration with shut-off valves, strainers, reducers, PRVs, rubber joints, and gauges ensures a safe, stable, and continuous water supply while making maintenance and pressure regulation easy.