DN2500& DN2600 Size Water Supply Projects

● Destination Poland

● Size DN2500 PN16,DN2600 PN10,Dn2600 PN16,DN2600 PN25

SPECIFICATION

● Material

Body: Ductile iron body EN GJS500-7

Gasket: EPDM

Tie Rods: Carbon steel grade 4.8 Dacromet coated bolts,nuts and washers

Surface: FBE coating inside and outside no less than 250um

Project Solution

Step 1

Our R&D team designed the drawing and send to our client for confirmation.For the big size,there have no dimension for big size flange.and our client also can’t offer the flange dimension.So our R&D calculated the flange dimension based on our experience and professional knowledge

Drawing details

Step 2

We produce the castings by lost foam craft, and machined the 100% surface according our own designed drawing.

Step 3

According to our QC department requirement,the Coarse shot blasting before machining and fine shot blasting before FBE coating are essential. The shot blasting process determines the stress and surface of the casting, which must be perfect.

Step 4

FBE coating

For large size dismantling joint, the preheating and spraying adhesion of castings in FBE coating are different from small size dismantling joint. According to the customer’s requirements ,the dismantling joint will be used above ground, so we use two different powders. After the casting was preheated, we first used pure epoxy FBE coating to ensure the adhesion of the FBE coating, and then we sprayed a layer of polyester FBE coating to ensure the FBE coating’s resistance to ultraviolet radiation. Because for large size dismantling joint, ordinary polyester powder cannot meet the requirements for good adhesion, and pure epoxy powder is not resistant to UV rays, so we fused the two types of powder to meet the requirements of good adhesion and good UV resistance.

Step 5

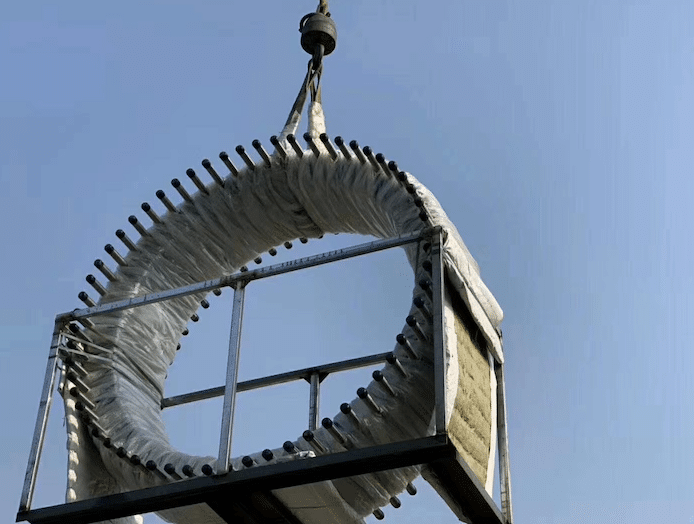

Assemble the EPDM gasket and tie rods ,and plastic protect cap on the tie rods.

Step 6

For big size dismantling joint, it can’t be loaded in normal container because the normal container is too small for them, you have to choose open top container.Base on open top container, we have to choose the right package method which can ensure the goods are shipped safely and without risk for rust because open top container is without cover on the container top.So our transport department formulated detailed packaging requirements, and the production department purchased suitable materials for the customization and improvement of packaging racks in accordance with the transport department’s packaging requirements, thus ensuring safe and convenient transport.

Note

The design and production of large size dismantling joint are both more complex compared to small size dismantling joint.

The requirements for production equipment and packaging are also higher.

Specific design and production solutions need to be developed according to the specific size.

If you need big size dismantling joint, consult judberd now.