Butterfly valve is a common valve used to switch and regulate the flow in the pipeline, the quality of the butterfly valve plays a pivotal role in the operation of the entire pipeline, so how to choose the right butterfly valve?

We have to consider from the following aspects.

Butterfly Valve Design

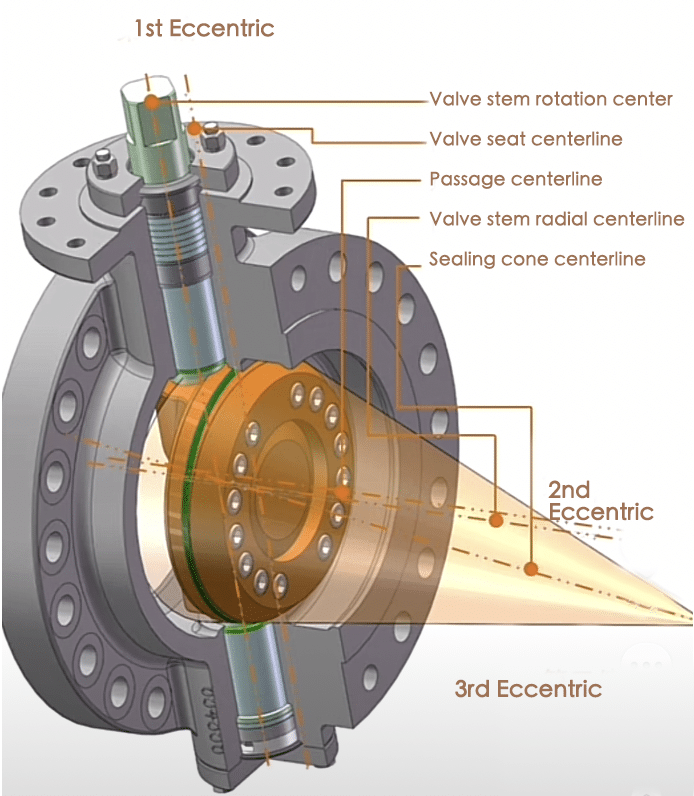

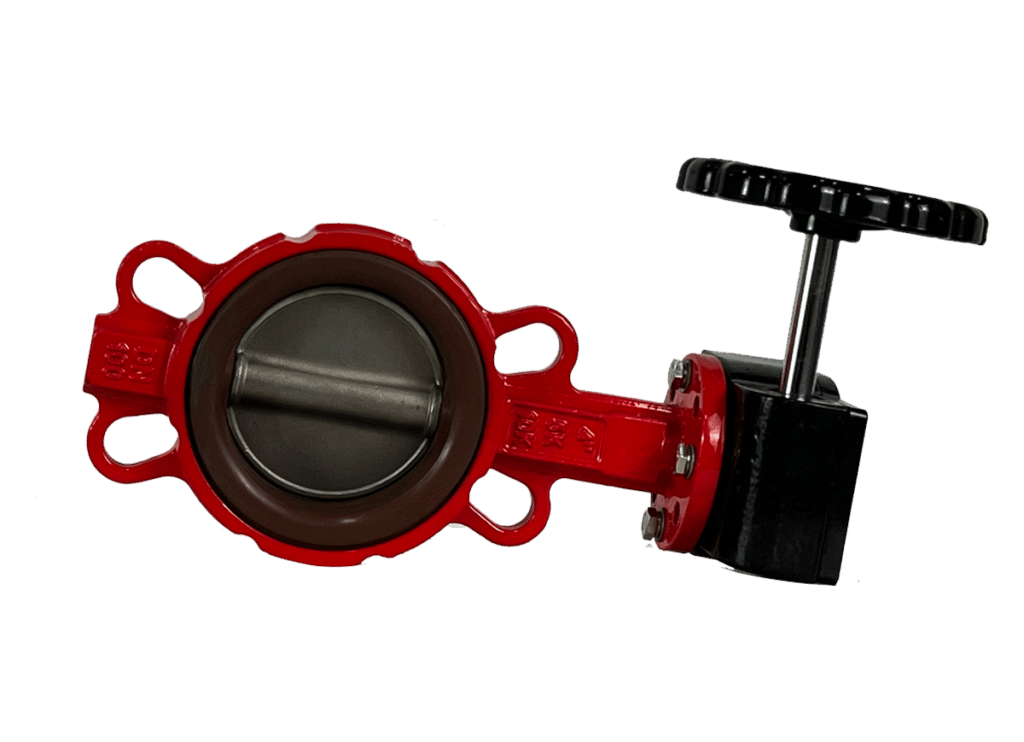

Butterfly valve include concentric butterfly valve, single eccentric butterfly valve, double eccentric butterfly valve and triple eccentric butterfly valve.

Concentric butterfly valve and single eccentric butterfly valve, relying on the valve plate and seat extrusion to form a seal, so it can only be a resilient seal, can not withstand high pressure and high temperature, the operating torque is large. So the concentric butterfly valve is generally smaller size, because the torque of large size is too large. And it can’t be used in high pressure and high temperature working condition.

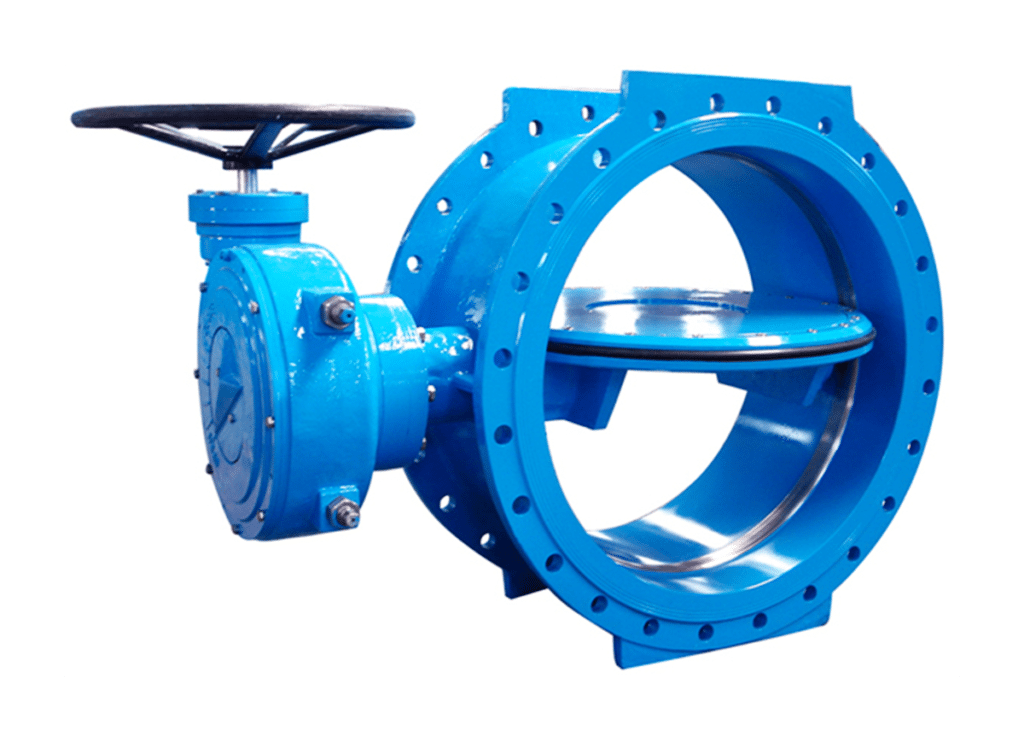

Judberd Concentric Butterfly Valve

Double eccentric butterfly valve’s valve stem, valve disc and valve body center is deviated, when the valve disc is opened, it can immediately get rid of the scraping with the valve seat. So it can be both resilient seal and metal seal, which greatly improves the high temperature resistance of the butterfly valve, but because of the strict requirements of the sealing position, it can’t withstand very high pressure.

Judberd Double Eccentric Butterfly Valve

Tripe eccentric butterfly valves do not rely on the elastic deformation of the valve seat, but rely on the valve seat contact surface pressure to achieve the sealing effect, can withstand both high temperature and high pressure, so it is selected to some high temperature and high pressure conditions.

Triple Eccentric butterfly valve

Butterfly Valve Body Material

Commonly used butterfly valve body materials are ductile iron, carbon steel, stainless steel, alloy, UPVC, CPVC, FRPP, PPR, ABS and so on.

Butterfly valve made of ductile iron, wear-resistant and corrosion-resistant, but not resistant to high pressure and high temperature, Applicable to working temperature between -30 ℃ -350 ℃, nominal pressure less than 4 Mpa pipeline .

Carbon steel butterfly valve, high pressure and high temperature resistance, so generally used for non-corrosive water, oil, gas and other high-pressure, high-temperature conditions, applicable to the operating temperature of -29 ℃ -425 ℃ of the substances and high pressure conditions.

Stainless steel butterfly valve, corrosion resistance, low temperature resistance, high temperature resistance, but high cost, generally used for corrosive substances or ultra-low temperature substances, temperature range -268 ℃ -649 ℃.

Copper alloy butterfly valve, available in 280 ℃ working conditions, the main material is bronze, bronze physical strength, structural stability so that it is particularly suitable for industrial production, other alloy butterfly valves and Monel alloy, Hastelloy, duplex stainless steel, titanium alloys

UPVC butterfly valve is a plastic material butterfly valve, a injection molding, light weight, corrosion resistance, lightweight operation, can more quickly cut off and regulate the flow rate.

Butterfly Valve Disc

Commonly used material for Butterfly valve disc is ductile iron, stainless steel, duplex steel.

Ductile iron valve disc is economical and durable, it will rust when it meets water, but it will not corrode so as to affect the sealing.

Stainless steel valve disc, will not rust, corrosion resistance, does not affect water quality

Duplex steel valve disc, desulfurization system commonly use duplex steel valve disc, common 2507, 1.4529, 1.4469, 2205 and other materials, with anti-scouring, chlorine corrosion resistance characteristics

Commonly used in water treatment plants is ductile iron valve disc, covered with nylon coating, this valve disc has the characteristics of corrosion resistance and not rusting

Rubber of rubber lined disc is generally the same material as the valve seat rubber, also plays a role in corrosion prevention, PTFE lined valve disc, mainly used in strong acid and alkali substances, has good corrosion resistance.

In addition to the material of the valve disc, the dimension of the valve disc design also have very strict requirements, if the valve disc is larger than correct one, it will cause the torque of the butterfly valve to become larger, if the dimension of the valve disc is smaller than correct one, it will cause the valve to leak.

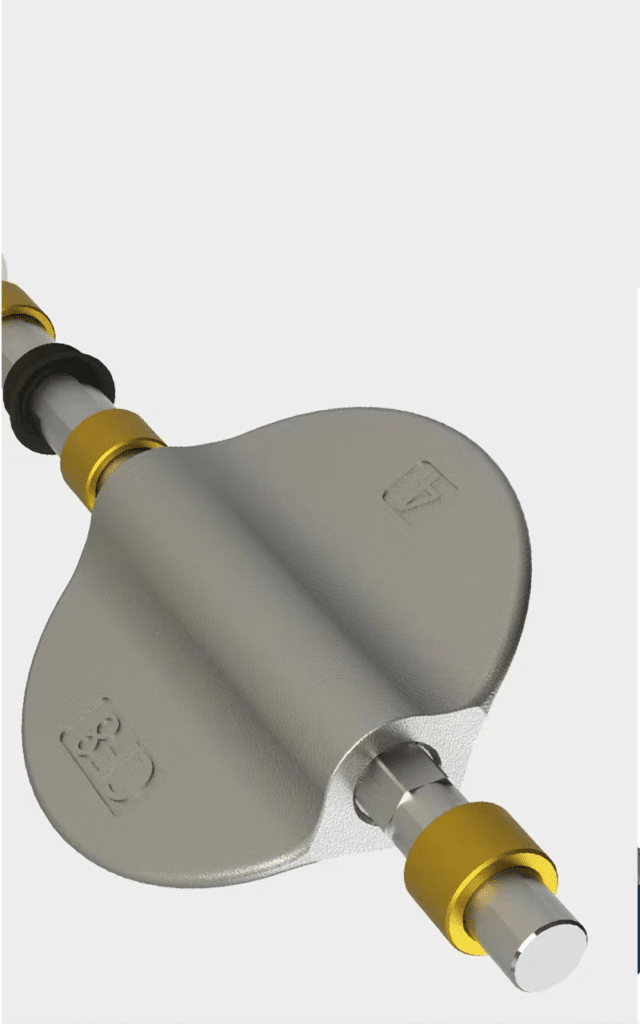

Valve Stem

Commonly used material for Valve stem are 45# steel and 2CR13, 45# steel is carbon steel, 2CR13 is stainless steel, compared with 45# steel, 2CR13 has better mechanical properties and corrosion resistance, higher cost. The valve stem is divided into two kinds, through shaft and half shaft.

Butterfly Valve Operation

Butterfly valve operation include lever, hand wheel, gear box, electric, pneumatic.

The advantage of lever is that it is easy to switch on and off, and it can be switched on and off at once, which is suitable for small diameter butterfly valves.

Judberd lever operated butterfly valve

For gear box operated butterfly valve, you needs to rotate the hand wheel to open and close the valve, which is more labor-saving for the handle, so it is more suitable for the butterfly valve of large diameter.

Gear Box Operated Butterfly Valve

For high altitude and high temperature conditions, the use of electric or pneumatic automatic control of the valve is more appropriate, especially pneumatic valves, more suitable for high-frequency switching conditions, common electric actuators include compact, QB-type, QT-type, DZW-type, in addition to the use of electric actuators to control, can also open or close the valve through the manual operation, these types of actuators and the corresponding intelligent type can be selected, intelligent type is Intelligent type can be connected to PLC system to realize intelligent remote control, and also can switch the valve by the knob on the actuator on the spot.

The common types of pneumatic actuators are AT-type, GT-type, and AW type, AT type compared to GT type, the quality is more stable, longer service life, AW type is often used in large diameter valves, these actuators can be added through the installation of accessories to achieve different functions, the manual mechanism allows pneumatic actuators to achieve the function of manually switching the valve, solenoid valves can control the valve open and close, the filter can filter out the vapor inside the gas source, but also to the inside of the cylinder injected with lubricant to improve service life. Limit switch can feedback the switch position of the valve, the positioner can control the valve opening angle, so as to realize the function of regulating the flow.

Electric Actuator Operated Butterfly Valve

Butterfly Valve with Pin ?Or Butterfly Valve without Pin?

Pinless butterfly valve has no pin and is driven through the positive hexagon of the valve stem and valve disc, which is not easy to leak from the pin. Easier to replace and repair. More resistant to high temperature and wear

Pinned butterfly valve, with the use of longer time, the substance is easy to penetrate from the pin to the space between the valve disc and valve stem, there will be wear and tear, internal leakage, fracture, affecting the service life of the valve.

So you need to choose the pinless type butterfly valve ,not pinned butterfly valve.

Valve Seat

Narrow sealing surface seat and wide sealing surface seat, wide seat can be installed directly with the flat welding flange, reducing the leakage between the valve and the flange.

Valve seat can be vulcanized seat, after the seat vulcanized to the valve body, the valve seat and the valve body becomes an integrated whole, reduce the corrosive substance leakage to the space between valve seat and the valve body, extend the service life of the valve.

Vulcanized Seat Butterfly Valve for Sea Water

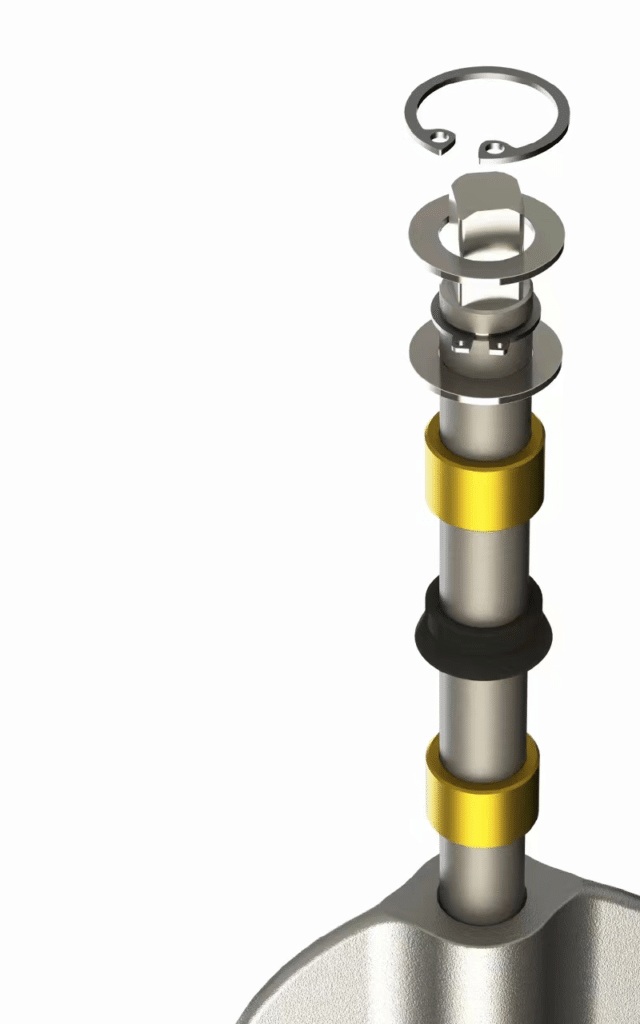

Bushing Material

Good bushings, such as copper bushings, can support the valve stem, and also reduce the opening and closing torque, with self-lubricating function, very wear-resistant.

Bronze Bushing Design(Yellow Color Parts)

Judberd is professional manufacturing vendor based in china for butterfly valve, if you have any query, welcome you contact us.