Tapping saddle with thread outlet-double bands or multiple bands for big size pipes installation instruction

We have clearly marked the applicable outer diameter of the main pipeline and the outlet size on each saddle clamp(as below figure). Before installation, please carefully check these markings to confirm they match the outer diameter of the main pipe and the required outlet size. Additionally, inspect all parts of the saddle clamp to ensure they are intact, especially the threaded parts. If necessary, please indicate whether you need thread protection caps when placing your order to prevent damage to the threads.

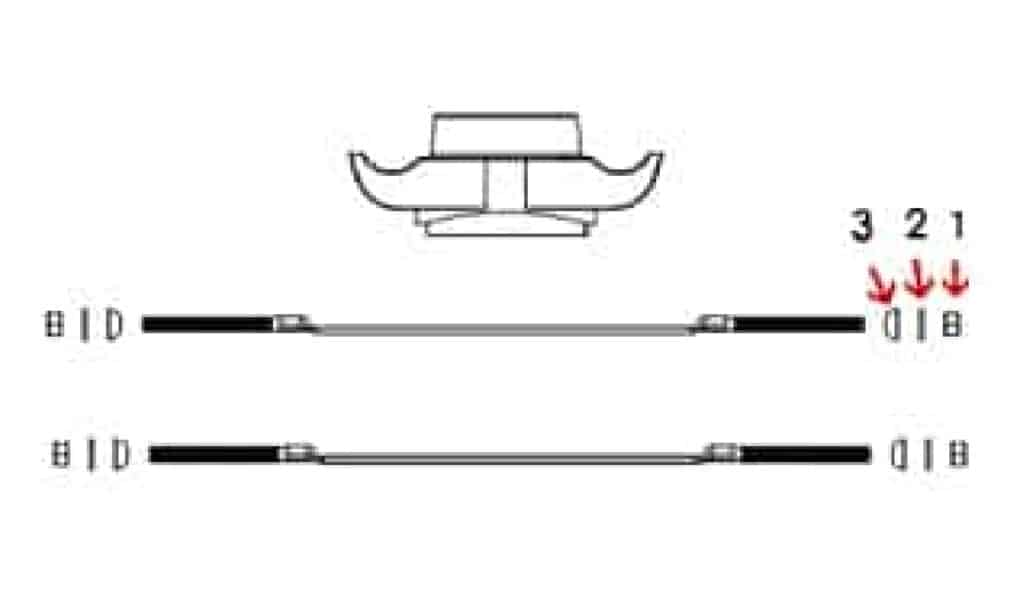

Step 1

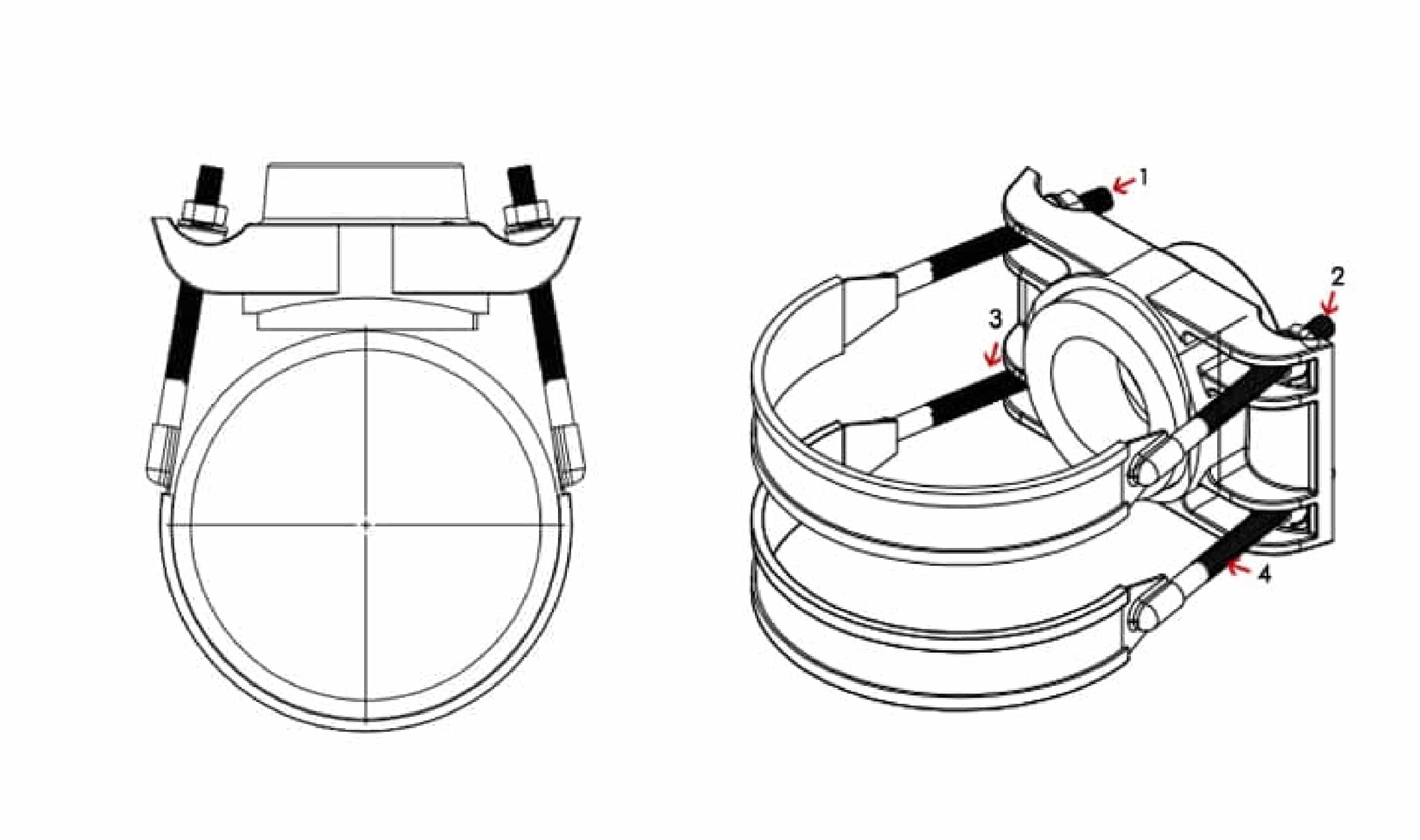

Disassemble the nuts(as right figure 1) ,washers(as right figure 2) and semi-Spherical washer(as right figure 3) at both ends of the steel bands.

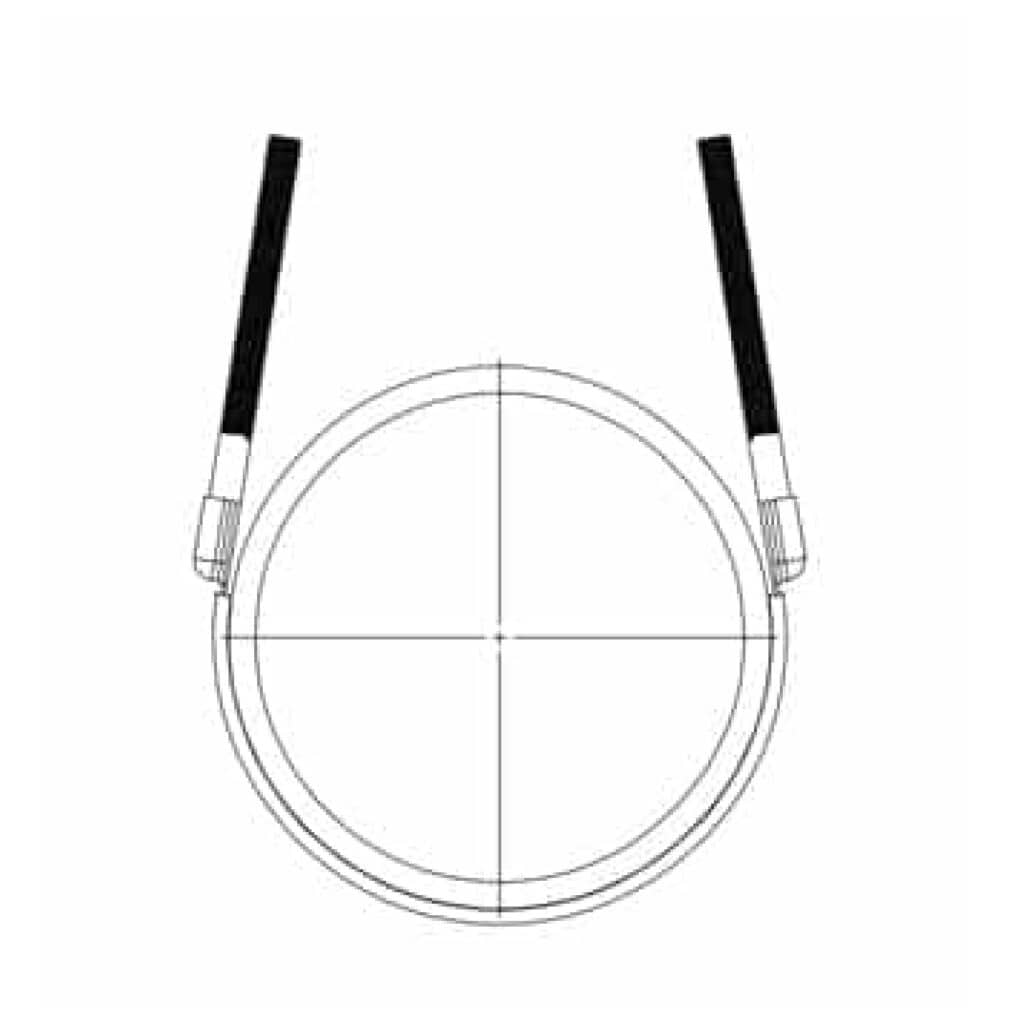

Step 2

Bend the steel bands so that they matches the curvature of the outer diameter of the pipe to be installed as left figure.

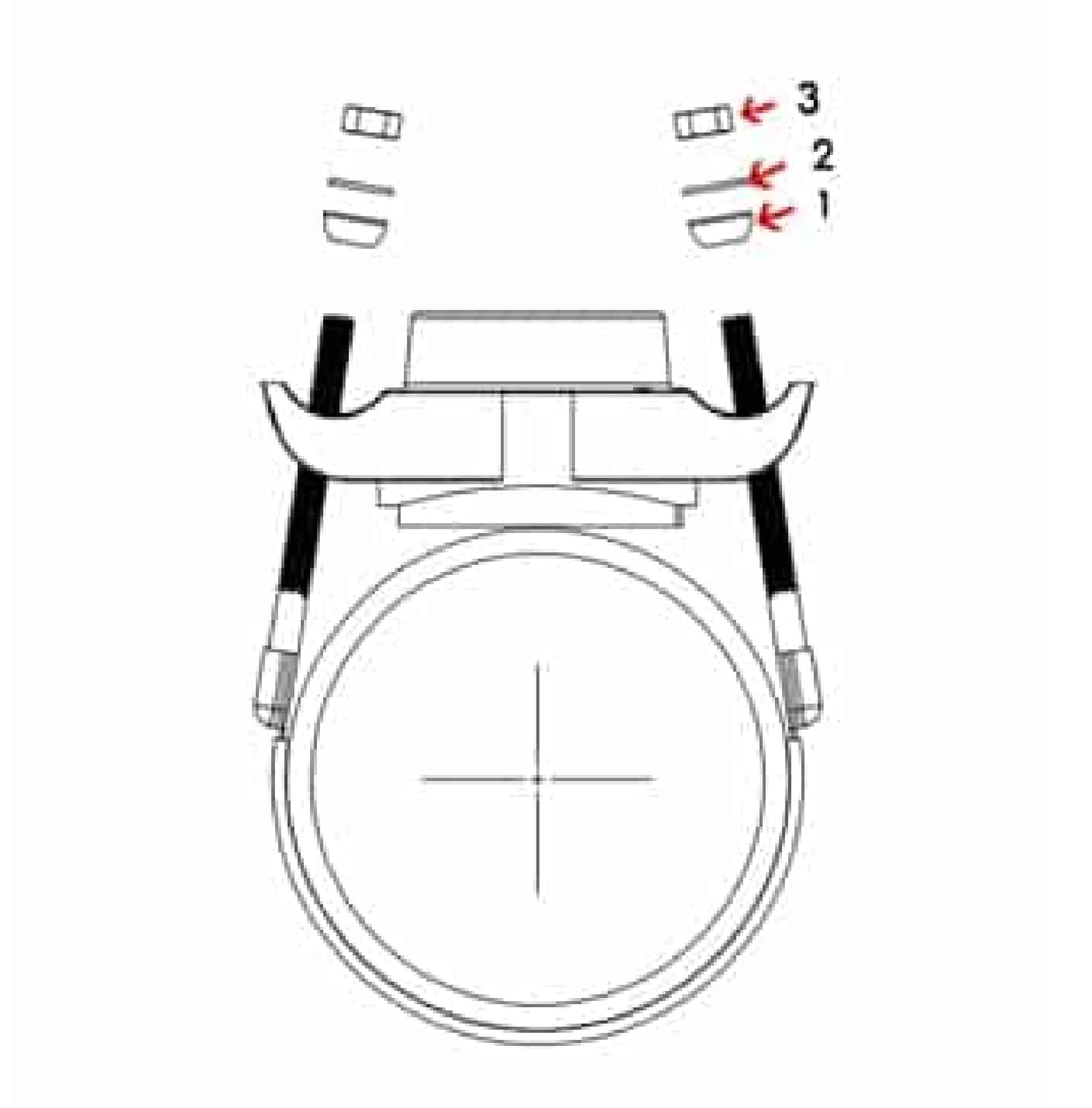

Step 3

Install ductile iron head onto the bent steel bands (as described in Step 2). Then, sequentially install the semicircular pad (as right Figure 1 ), the washer (as right Figure 2 ), and the nut (as right Figure 3), following the diagram as below.

Step 4

Tighten the four nuts alternately in multiple turns as left figure 1-2-3-4, ensuring equal force for all nuts during each turn. Gradually increase the force from low to high until reaching the required torque.

Step 5

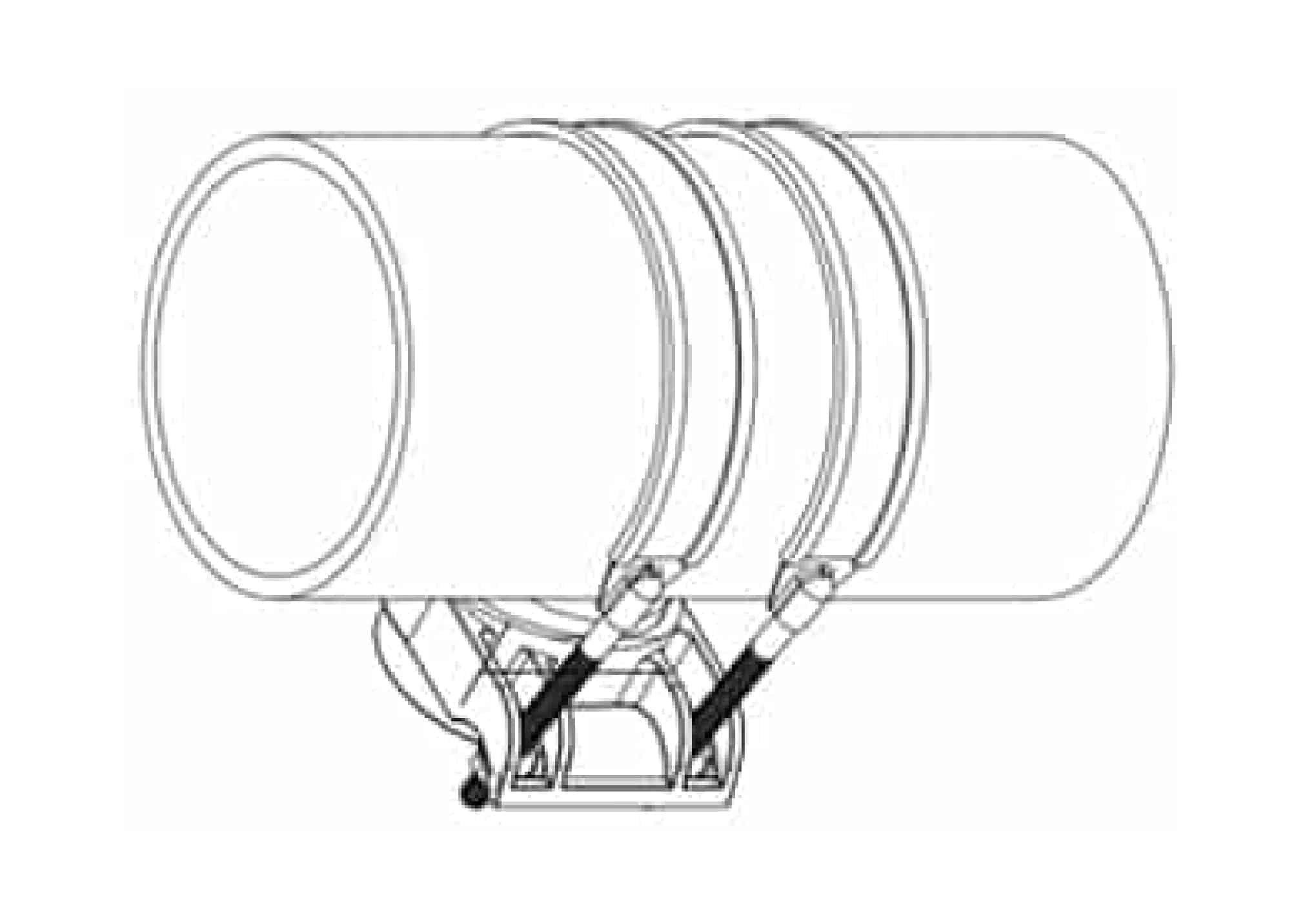

Assembling was finished as right photo.