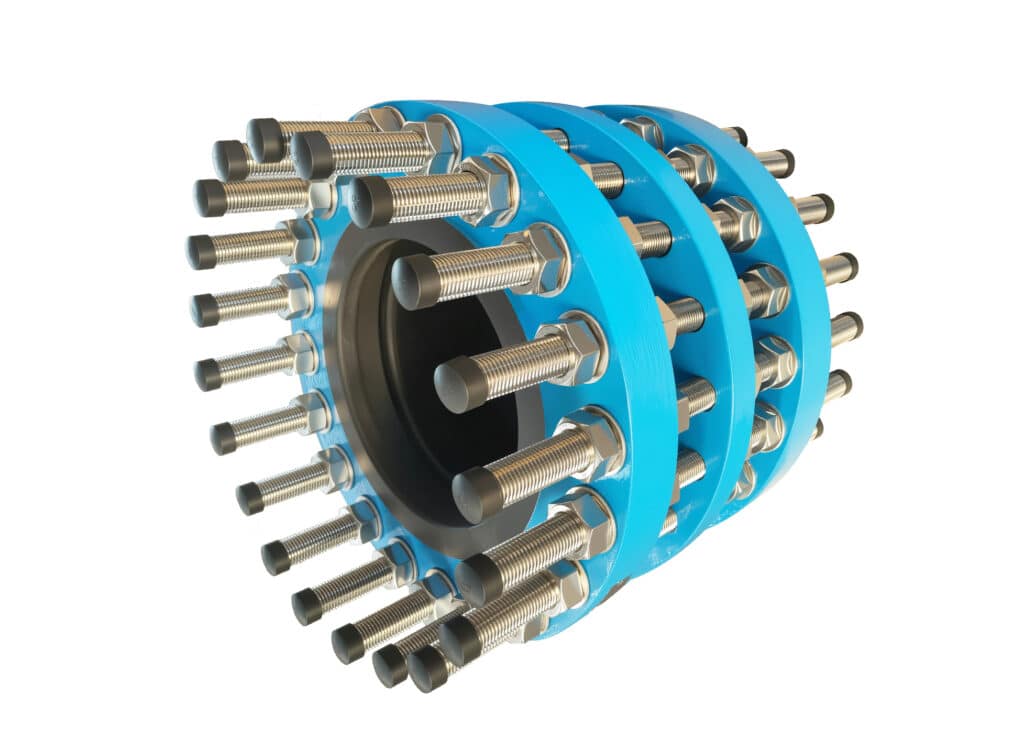

MS DISMANTLING JOINT

The MS dismantling joint is made by welding carbon steel flange and Seamless steel pipe or carbon steel plate, it can withstand pressures from PN6 to PN100 which is much more higher than ductile iron dismantling joint, no need moulds.

SPECIFICATION

● Design standard EN545,ISO2531,AWWA C219,AS/NZS2280

● Material Q235,Q235B,Q275 etc carbon steel material

● Joint type V type

● Welding method Automatic submerged arc welding

● Test standard ISO17640:2010

● Ultrasonic testing, penetration testing, pressure testing are available

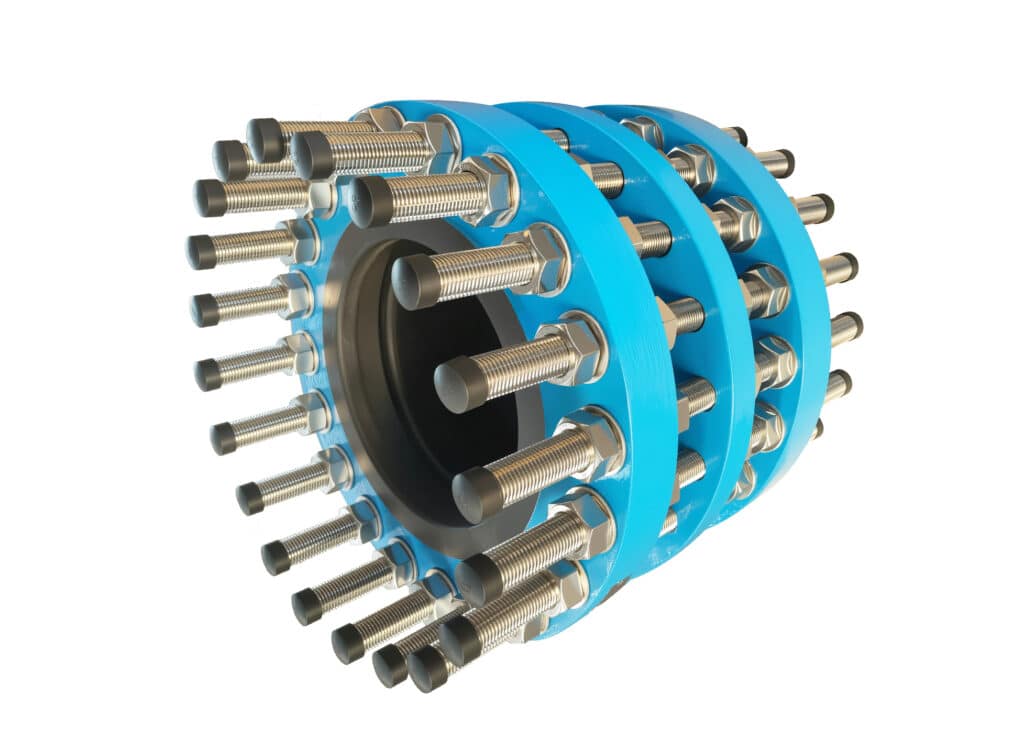

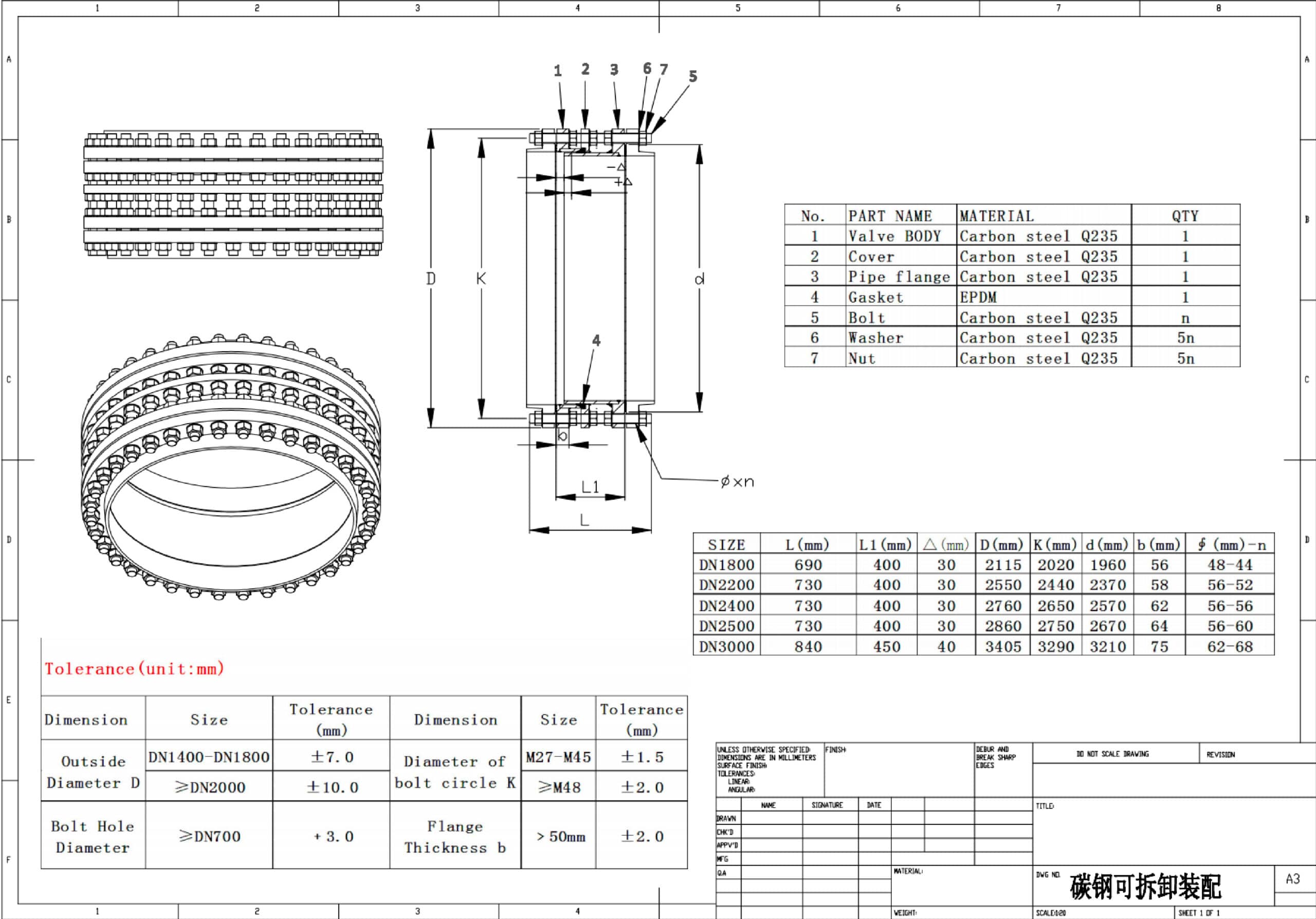

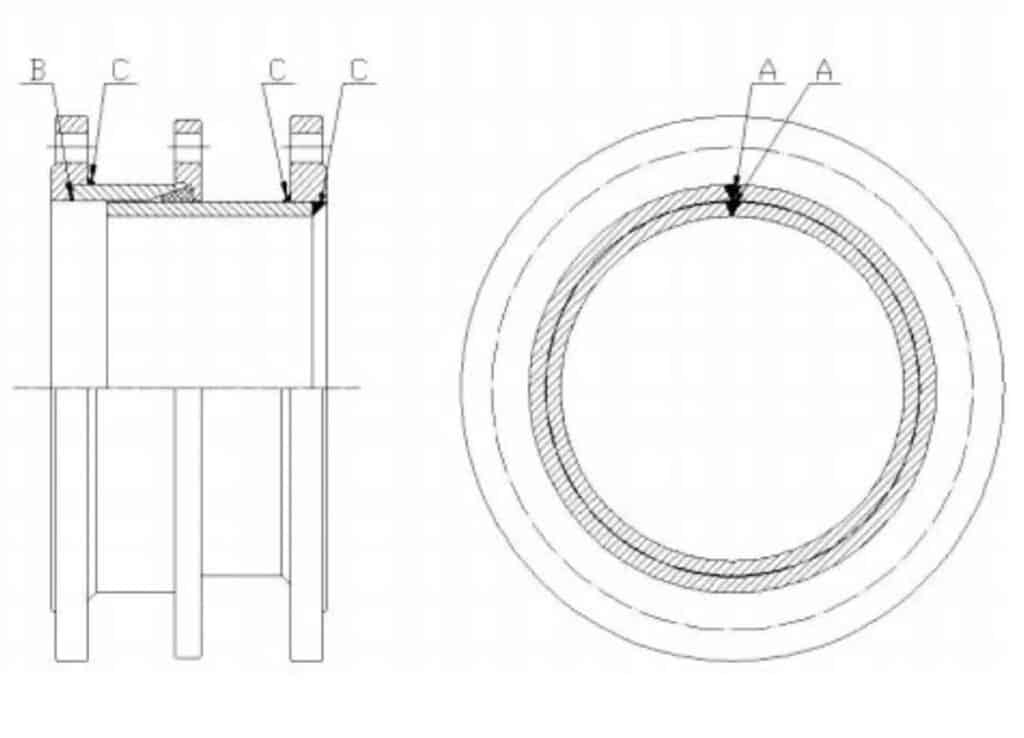

Drawing

We can design MS dismantling joint according to projectreguirement.

Heavy Duty Type

Light Duty Type

HOW TO WELD FOR MS DISMANTLING JOINT?

PART A

Welding form butt joint

The groove form is double V-shaped groove,

flat welding Welding process Submerged Arc Welding

Welding material J422 size:3.2 4.0 5.0

Multi-layer welding

Welding by manual

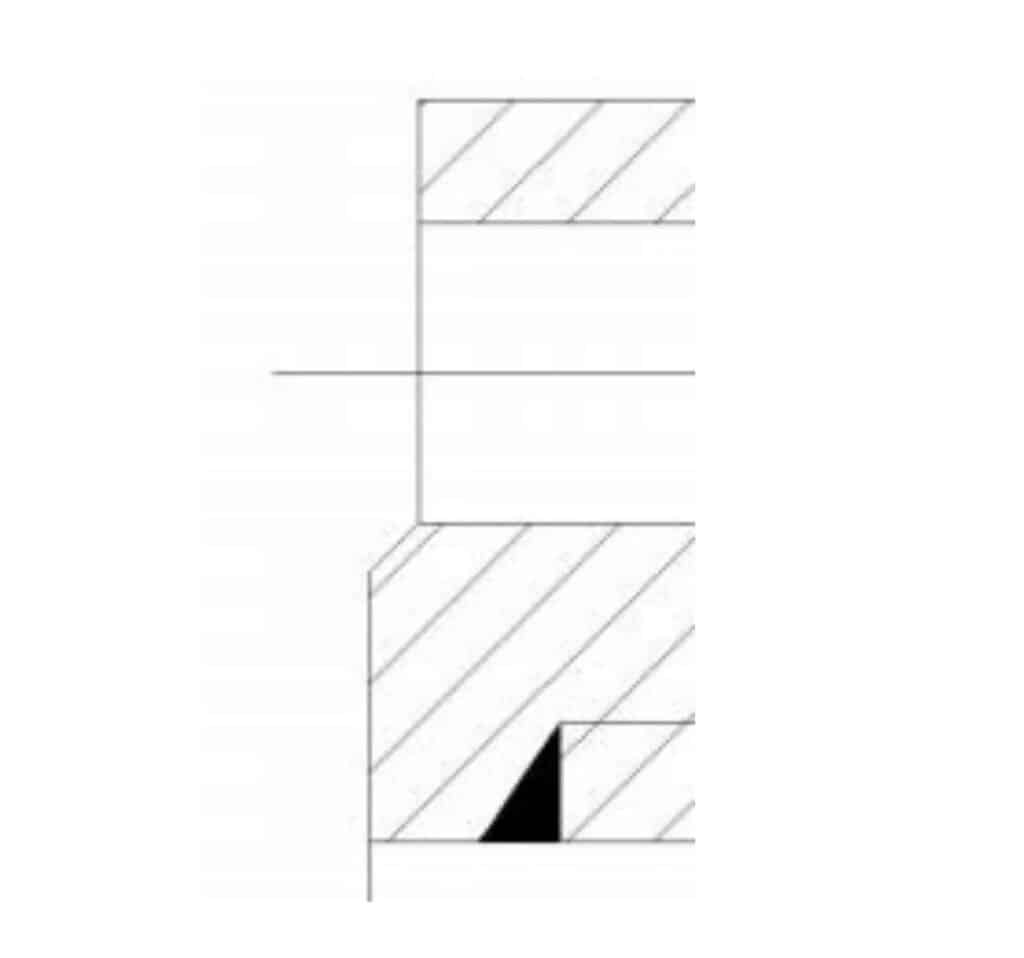

PART B

Welding form butt joint

The groove form is Single V-groove, flat welding

Welding process Submerged Arc Welding

Welding material J422 size:3.2 4.0 5.0

single-pass welding

Welding by manual

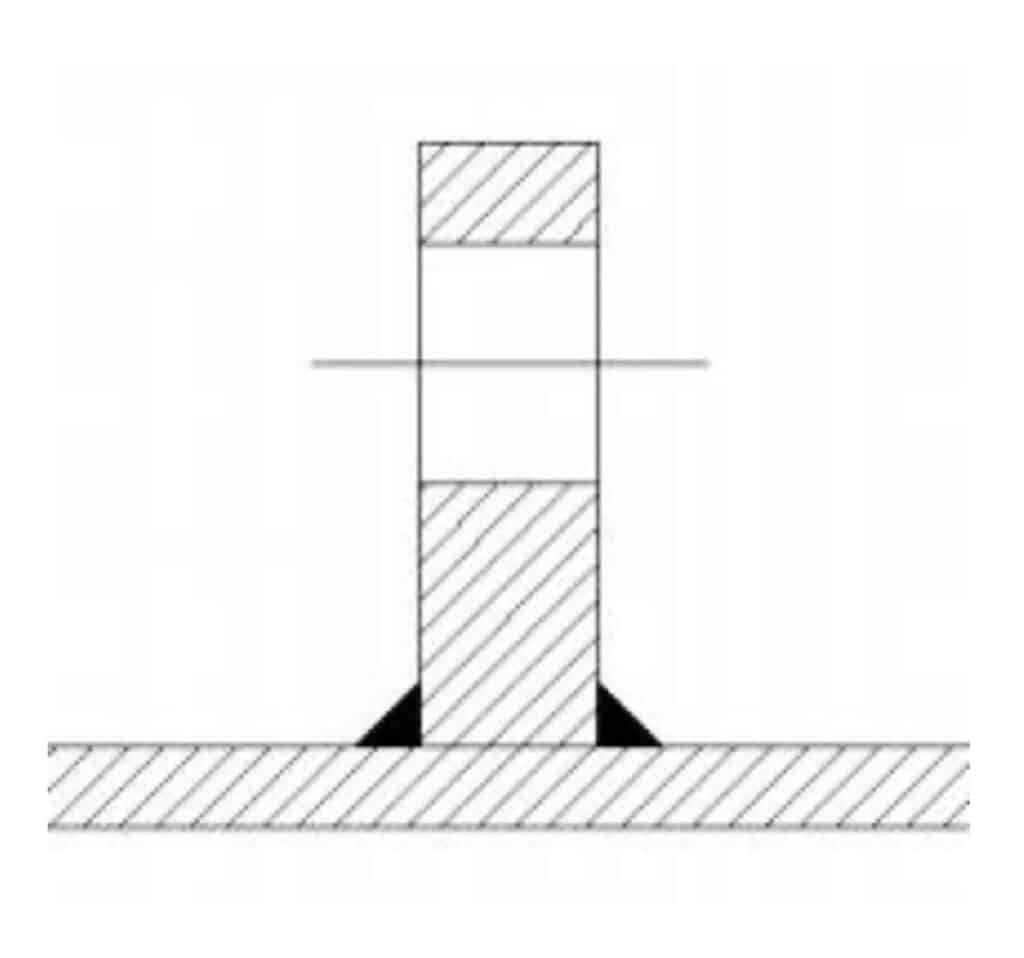

PART C

Welding form Fillet joint

The groove form is 45° Fillet

Welding process Arc welding

Welding material Gas 80%Ar 、20%CO2

single-pass welding

Welding by Machine

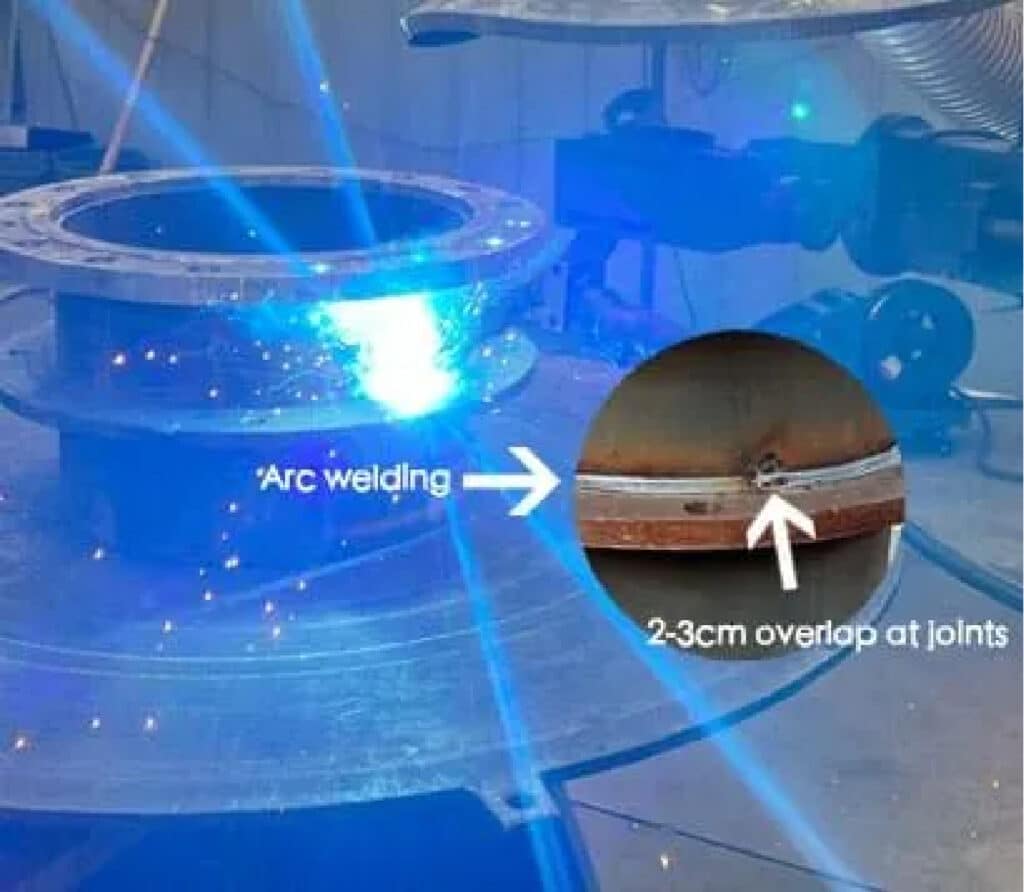

SUBMERGED ARC WELDING PROCESS

PREPARE

LOCATION

WELDING

FINISHED

PENETRATION TESTING PROCESS FOR MS DISMANTLING JOINT

01

After the dismantling joint surface is smeared with the penetrating liquid with coloring dye, under the influence of capillarity, after a period of time, the penetrating liquid can penetrate into the surface vacancy.

02

Removing the excess penetrating liquid on the dismantling joint surface, then smearing the imaging agent on the dismantling joint surface. Under the influence of capillarity, the imaging agent attracts the penetrading liquid saved in the surface vacancy, the penetrating liquid will seep back into the imaging agent. The morphology and distribution of defects are detected under a certain light source.