Socket Bend

Socket Bend refers to a pipe fitting that allows for a change in direction in a piping system. It typically involves a socket where the end of a pipe can be inserted and connected. The socket bend is designed to provide a secure and leak-proof connection, ensuring the fluid or gas being transported can change direction smoothly without leaks or other issues.

EN545 Double Socket 45 Degree Bend for DI Pipe

EN545 Single Socket 45 Degree Bend for DI Pipe

Socket Bend Drawing

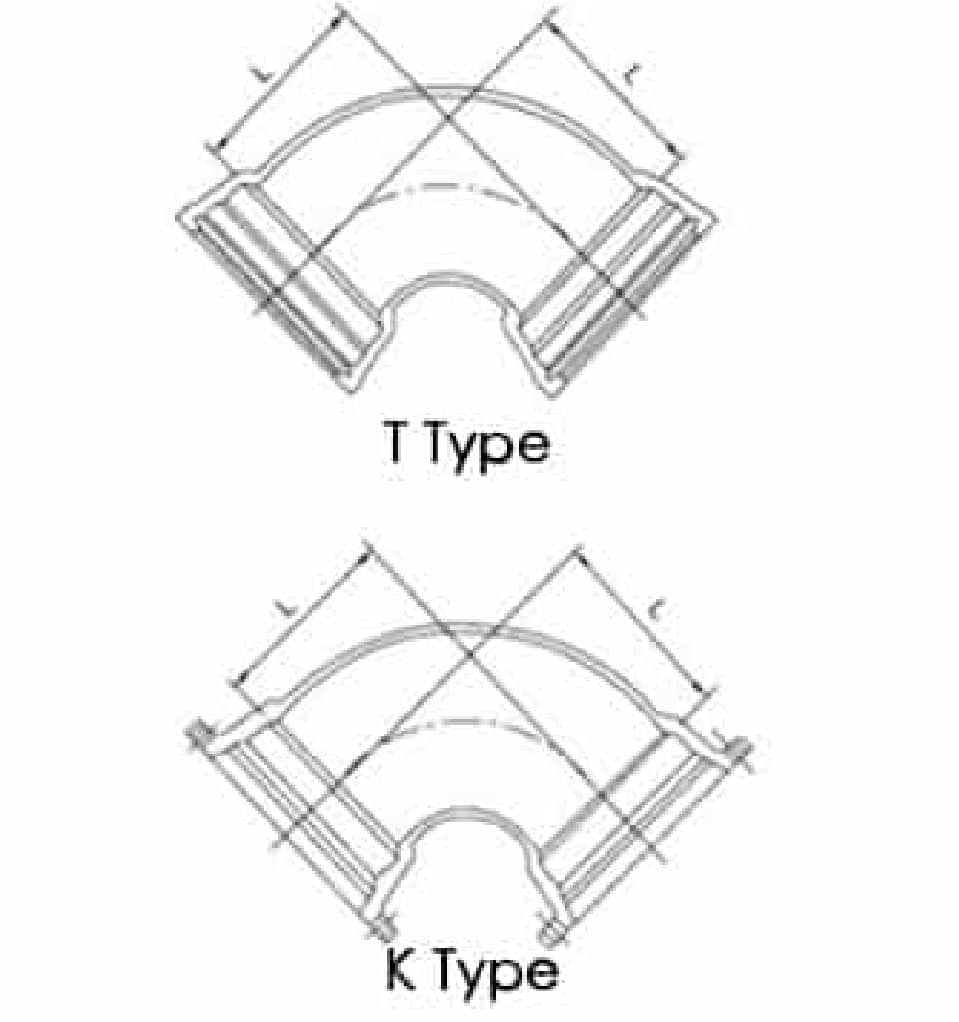

Double Socket 90° Bend Drawing

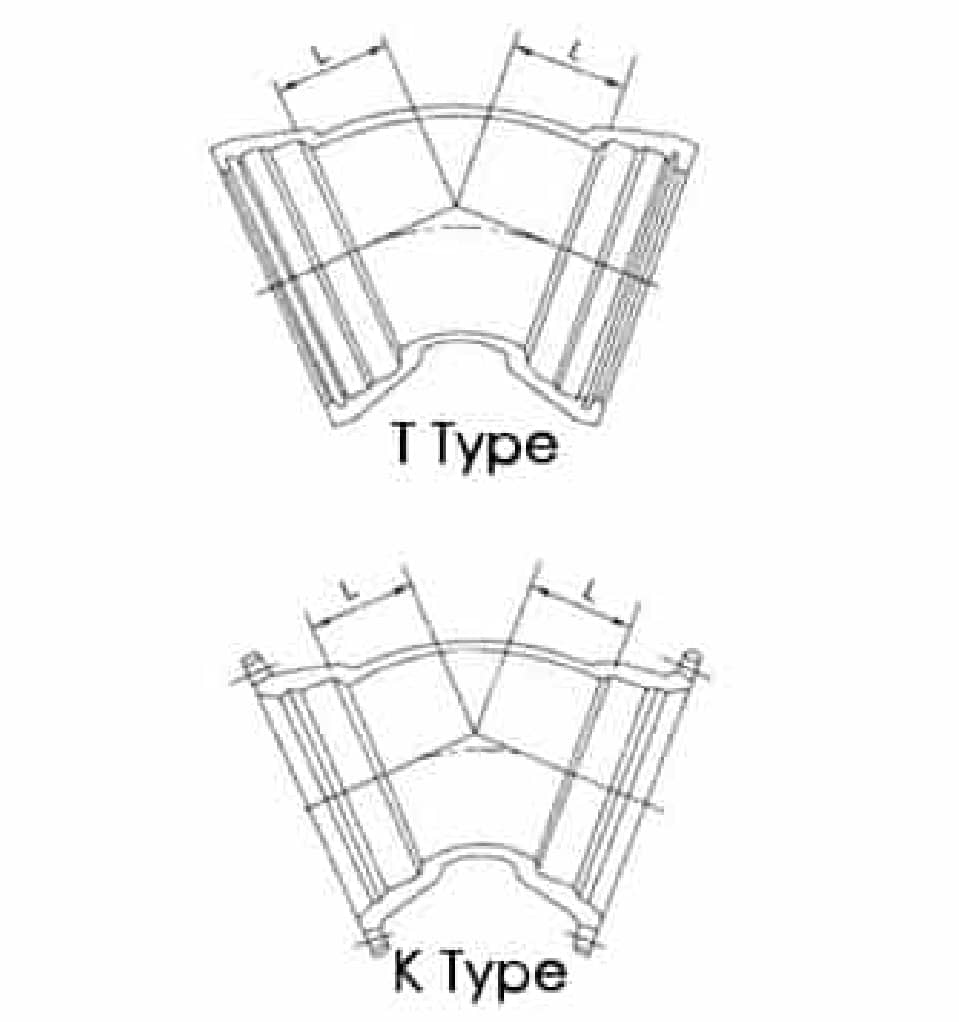

Double Socket 45° Bend Drawing

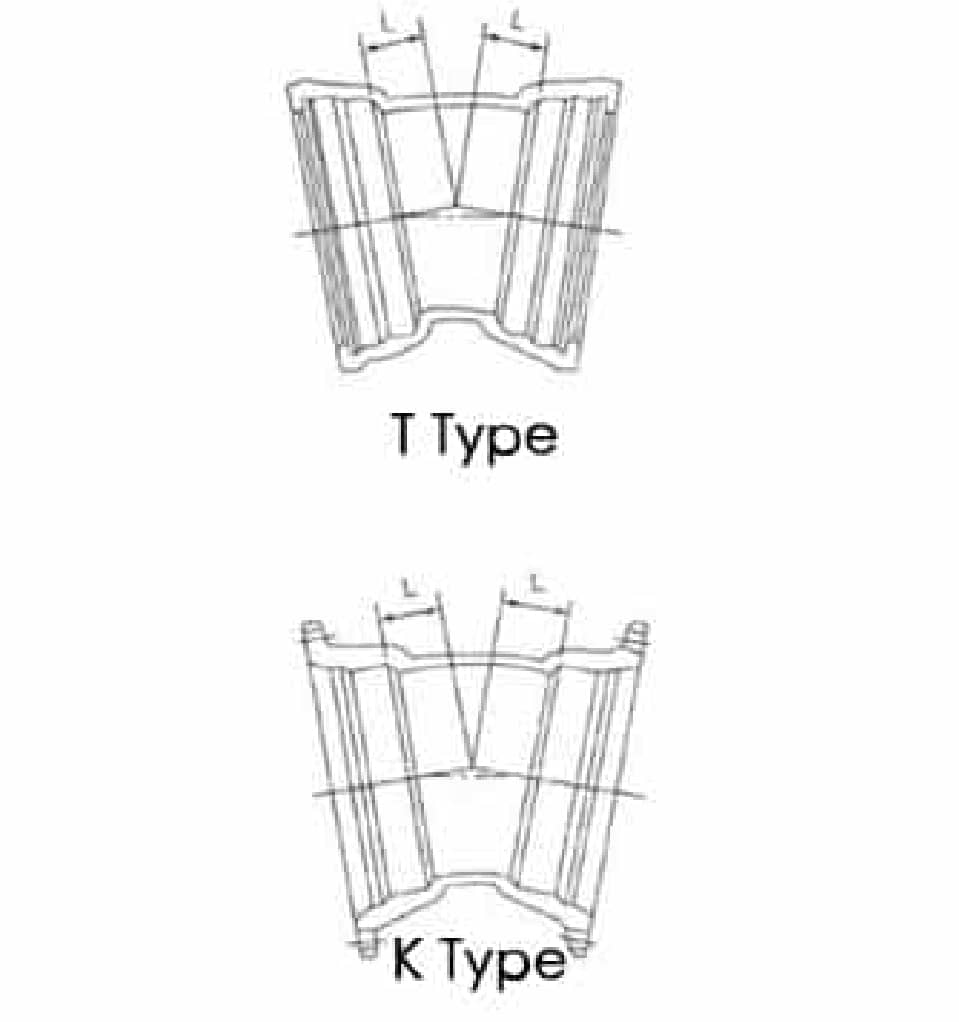

Double Socket 22.5° Bend Drawing

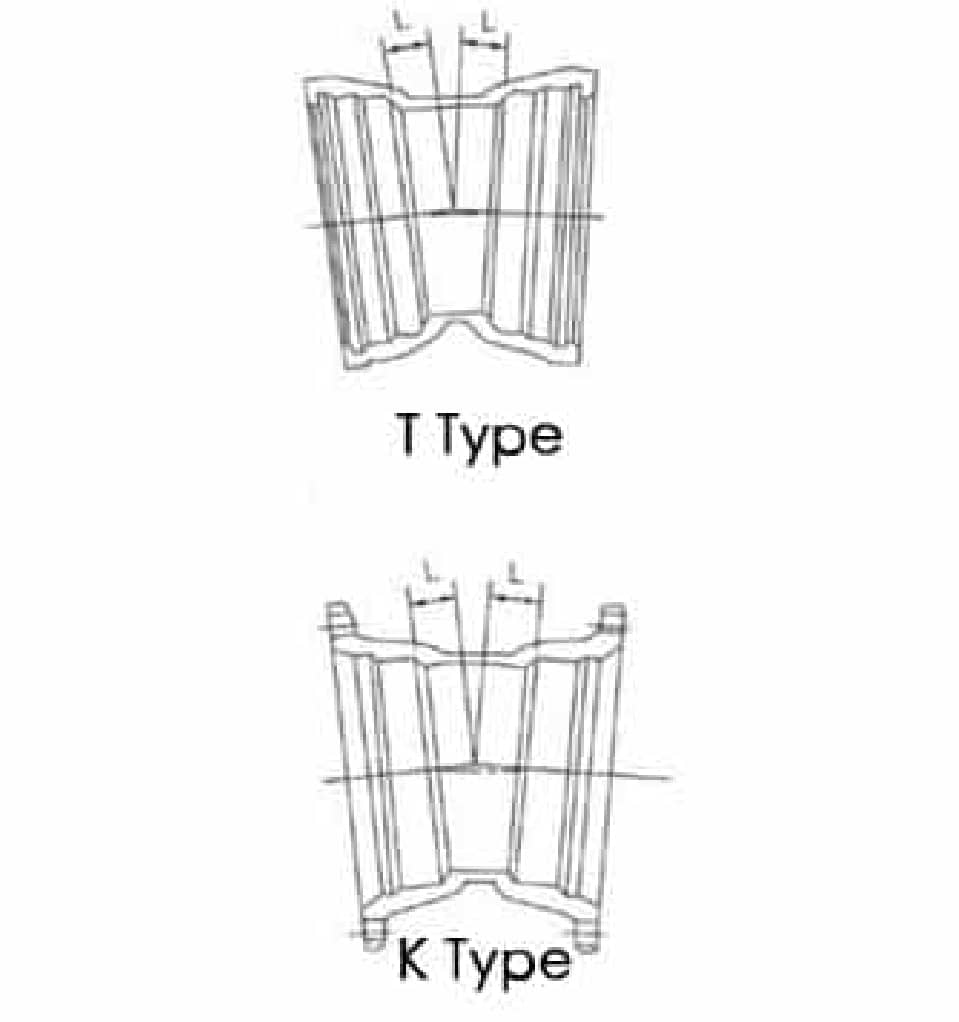

Double Socket 11.25° Bend Drawing

Socket Bend Dimension

Double Socket 90° Bend Dimension

K=12

| Nominal Diameter DN | L | Mass (kg) T Type | Mass (kg) K Type |

|---|---|---|---|

| 80 | 100 | 8.6 | 12 |

| 100 | 120 | 11.5 | 15.6 |

| 150 | 170 | 20.5 | 27.5 |

| 200 | 220 | 33 | 40 |

| 250 | 270 | 48.5 | 55.5 |

| 300 | 320 | 68 | 81.5 |

| 350 | 370 | 83 | 105 |

| 400 | 420 | 143 | 134 |

| 450 | 470 | 156 | 166 |

| 500 | 520 | 183 | 202 |

| 600 | 620 | 273 | 290 |

| 700 | 720 | 455 | 408 |

| 800 | 820 | 605 | 544 |

| 900 | 920 | 813 | 720 |

| 1000 | 1020 | 1045 | 935 |

| 1200 | 1220 | 1508 | 1444 |

| 1400 | 1220 | 2419 | 1918 |

| 1600 | 1290 | 3382 | 2543 |

| 1800 | 1320 | 3616 | 3229 |

| 2000 | 1360 | 4516 | 4033 |

Double Socket 45° Bend Dimension

K=12

| Nominal Diameter DN | L | Mass (kg) T Type | Mass (kg) K Type |

|---|---|---|---|

| 80 | 55 | 7.7 | 11.1 |

| 100 | 65 | 10.1 | 14.3 |

| 150 | 85 | 17.5 | 24 |

| 200 | 110 | 27 | 34 |

| 250 | 130 | 38.5 | 45.5 |

| 300 | 150 | 53 | 66 |

| 350 | 175 | 70 | 83.5 |

| 400 | 195 | 89 | 104 |

| 450 | 220 | 117 | 127 |

| 500 | 240 | 139 | 150 |

| 600 | 285 | 202 | 209 |

| 700 | 330 | 282 | 289 |

| 800 | 370 | 378 | 373 |

| 900 | 415 | 496 | 488 |

| 1000 | 460 | 635 | 628 |

| 1200 | 550 | 986 | 943 |

| 1400 | 515 | 1273 | 1223 |

| 1600 | 565 | 1740 | 1647 |

| 1800 | 610 | 2296 | 2166 |

| 2000 | 660 | 2970 | 2791 |

Double Socket 22.5° Bend Dimension

K=12

| Nominal Diameter DN | L | Mass (kg) T Type | Mass (kg) K Type |

|---|---|---|---|

| 80 | 40 | 7.5 | 10.7 |

| 100 | 40 | 9.5 | 13.5 |

| 150 | 55 | 15.9 | 22.5 |

| 200 | 65 | 24 | 30.5 |

| 250 | 75 | 33.5 | 40.5 |

| 300 | 85 | 44.5 | 58 |

| 350 | 95 | 58 | 71 |

| 400 | 110 | 74 | 88 |

| 450 | 120 | 95 | 105 |

| 500 | 130 | 111 | 123 |

| 600 | 150 | 157 | 164 |

| 700 | 175 | 217 | 223 |

| 800 | 195 | 287 | 281 |

| 900 | 220 | 373 | 364 |

| 1000 | 240 | 470 | 463 |

| 1200 | 285 | 716 | 671 |

| 1400 | 260 | 933 | 882 |

| 1600 | 280 | 1259 | 1167 |

| 1800 | 305 | 1663 | 1533 |

| 2000 | 330 | 2114 | 1965 |

Double Socket 11.25° Bend Dimension

K=12

| Nominal Diameter DN | L | Mass (kg) T Type | Mass (kg) K Type |

|---|---|---|---|

| 80 | 30 | 7.1 | 10.5 |

| 100 | 30 | 8.9 | 13.1 |

| 150 | 35 | 14.8 | 21.5 |

| 200 | 40 | 22 | 29 |

| 250 | 50 | 30.5 | 37.5 |

| 300 | 55 | 40.5 | 54 |

| 350 | 60 | 52 | 65.5 |

| 400 | 65 | 65 | 79 |

| 450 | 70 | 83.5 | 93.5 |

| 500 | 75 | 96 | 108 |

| 600 | 85 | 134 | 141 |

| 700 | 95 | 181 | 187 |

| 800 | 110 | 239 | 234 |

| 900 | 120 | 305 | 297 |

| 1000 | 130 | 381 | 375 |

| 1200 | 150 | 568 | 524 |

| 1400 | 130 | 747 | 697 |

| 1600 | 140 | 1007 | 914 |

| 1800 | 155 | 1331 | 1200 |

| 2000 | 165 | 1702 | 1522 |

Socket Bend Application

Ductile iron socket bends can be used to connect the socket of ductile iron pipes or PVC pipes with T-shaped rubber rings. The T-shaped rubber ring has two different hardnesses, which can play the roles of fixing and sealing respectively. When the socket moves outward, the sealing performance of the rubber ring will be better.

The design of this connection method ensures the reliability and durability of the pipeline system. The double hardness design of the T-shaped rubber ring can make the pipeline stable and firm during the connection process, and provide excellent sealing performance. The harder part provides mechanical support to prevent the pipe from moving, while the softer part can adapt to the slight deformation of the pipe to ensure sealing.

In addition, the flexible nature of the rubber ring can further enhance the sealing performance when the socket moves outward, preventing any leakage. This feature is particularly important in pipeline systems that need to be frequently moved or subjected to external pressure.

Overall, ductile iron pipes and PVC pipes connected with T-shaped rubber rings have the following advantages:

RELIABLE SEALING PERFORMANCE

The double hardness design ensures efficient sealing at the pipe connection, preventing leakage.

STRONG ADAPTABILITY

Can withstand slight movements and deformations of the pipe, suitable for various complex installation environments.

EASY INSTALLATION

Fast installation and connection can be achieved without special tools, saving time and cost.

HIGH DURABILITY

Superior corrosion resistance and compressive strength, suitable for a variety of industrial and municipal applications.

This connection method not only improves the stability and reliability of the pipeline system, but also extends the service life, reduces the frequency of maintenance and replacement, and is a very efficient and practical solution in modern pipeline engineering.