Pipe Dismantling Joint

Judberd’s dismantling joint features a very simple and practical design.

Sealing is achieved by compressing the gasket with a centrally positioned, independent gland and very short bolts, making installation extremely quick and easy.

If the pipeline is laid on very stable ground, with no significant movement caused by ground settlement, thermal expansion, or contraction that could compromise the seal, then long tie rods are not required. In this case, the dismantling joint is a non-thrust type dismantling joint.

On the other hand, if the pipeline is subject to external forces that may cause movement and lead to seal failure, long tie rods must be installed. In this case, the dismantling joint becomes a thrust type dismantling joint.

Feature

● Flange Drilled according to EN1092-1/ASME B16.5/ASME B16.47

● Adjustable Length can be customized

● Both thrust type and non thrust type are available

● Material Flange carbon steel S-235-JR with carbon steel or Stainless steel middle sleeve, FBE coating no less than 250um

● With EPDM gasket for water

● With Carbon Steel or Stainless Steel tie rods

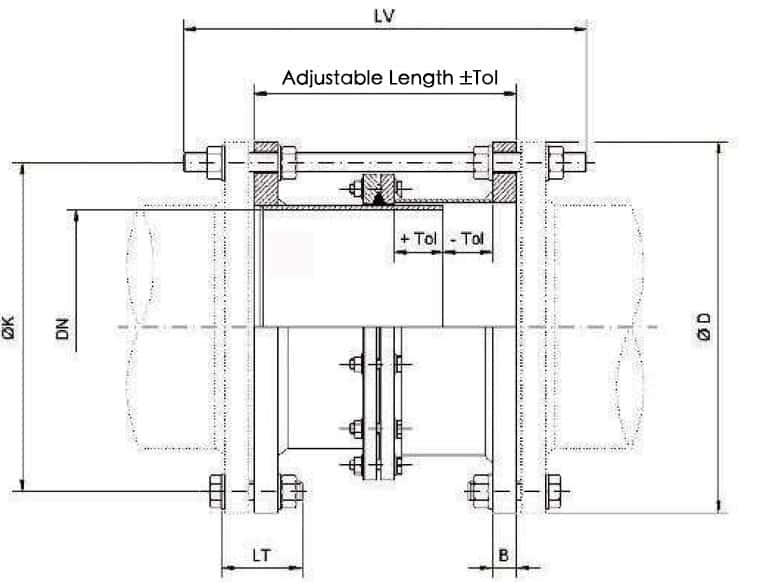

Drawing

Dimension

| DN | Adjustable Length | ФD | ФK | N | M | LV | LT | B |

|---|---|---|---|---|---|---|---|---|

| 50 | 200±30 | 165 | 125 | 4 | 16 | 330 | 70 | 18 |

| 65 | 200±30 | 185 | 145 | 4 | 16 | 330 | 70 | 18 |

| 80 | 200±30 | 200 | 160 | 8 | 16 | 330 | 70 | 20 |

| 100 | 200±30 | 220 | 180 | 8 | 16 | 330 | 70 | 20 |

| 125 | 200±30 | 250 | 210 | 8 | 16 | 330 | 70 | 22 |

| 150 | 200±30 | 285 | 240 | 8 | 20 | 330 | 80 | 22 |

| 200 | 280±40 | 340 | 295 | 8 | 20 | 430 | 80 | 24 |

| 250 | 280±40 | 395 | 350 | 12 | 20 | 430 | 80 | 26 |

| 300 | 280±40 | 445 | 400 | 12 | 20 | 430 | 80 | 26 |

| 350 | 280±40 | 505 | 460 | 16 | 20 | 430 | 80 | 28 |

| 400 | 280±40 | 565 | 515 | 16 | 24 | 450 | 100 | 32 |

| 450 | 280±40 | 615 | 565 | 20 | 24 | 450 | 100 | 38 |

| 500 | 330±50 | 670 | 620 | 20 | 24 | 530 | 100 | 38 |

| 600 | 330±50 | 780 | 725 | 20 | 27 | 550 | 120 | 38 |

| 700 | 330±50 | 895 | 840 | 24 | 27 | 550 | 120 | 40 |